Factory Quality High Strength Spring Steel Wire

Product Description

The quality of the galvanized layer can be evaluated by the weight of the galvanized substrate, the adhesion between the galvanized layer and the substrate and the uniformity of the coating. The uniformity of the zinc layer is an important quality index of the zinc layer, and the corrosion always starts at the thinnest part of the zinc layer and spreads around in general use, resulting in rust and broken wires that affect the service life. For the weight and adhesion of the coating, the standards have clear provisions, but the uniformity is different, in the 70s of the 20th century, ISO standards and standards around the world generally stipulate the use of copper sulfate test to test.

By the 80s, with the exception of Japan and the former Soviet Union, ISO standards and standards from all over the world no longer used this method. Although China retains this method in some standards such as GB/T15393-94 "steel wire galvanized layer" in the way of "both parties can be carried out by agreement", most of them are no longer used. However, the old zinc layer uniformity detection method has been discarded but no corresponding new method has been established, and there is no unified definition and requirement for uniformity, so that some producers have not well monitored and tested the uniformity of the coating, which has affected the further improvement of product quality

By the 80s, with the exception of Japan and the former Soviet Union, ISO standards and standards from all over the world no longer used this method. Although China retains this method in some standards such as GB/T15393-94 "steel wire galvanized layer" in the way of "both parties can be carried out by agreement", most of them are no longer used. However, the old zinc layer uniformity detection method has been discarded but no corresponding new method has been established, and there is no unified definition and requirement for uniformity, so that some producers have not well monitored and tested the uniformity of the coating, which has affected the further improvement of product quality

Product Parameters

| Material | Q195/Sae1006/Sae1008/Sea1020 |

| Tolerance | ±5% |

| Standard | ASTM/GB |

| Processing services | Cutting/Bending |

| Shipping date | 15-21days |

| Price terms | FOB/CFR/CIF/EXW/ETC |

| Application | Construction |

| Package | Standard Sea-worthy Packing |

| Galvanized steel wire | |||||

| Diameter (mm) | Tolerance (mm) | Tensile Strength No Less Than (MPA) | Torsion Test No less Than (times) | Bend Times No Less Than (times) | Zinc Coating Mass No Less Than (g/m2) |

| 0.45 | +/-0.01 | 1770 | 28 | 5 | 5 |

| 0.5 | +/-0.01 | 1770 | 28 | 5 | 5 |

| 0.6 | +/-0.01 | 1770 | 28 | 9 | 5 |

| 0.7 | +/-0.01 | 1670 | 28 | 7 | 10 |

| 0.8 | +/-0.01 | 1670 | 28 | 13 | 10 |

| 0.9 | +/-0.02 | 1570 | 28 | 11 | 15 |

| 1 | +/-0.02 | 1470 | 27 | 9 | 20 |

| 1.2 | +/-0.02 | 1470 | 27 | 15 | 20 |

| 1.3 | +/-0.02 | 1370 | 27 | 13 | 20 |

| 1.4 | +/-0.02 | 1370 | 27 | 11 | 20 |

| 1.6 | +/-0.03 | 1370 | 27 | 13 | 20 |

| 1.8 | +/-0.03 | 1370 | 27 | 11 | 30 |

| 2 | +/-0.03 | 1270 | 25 | 10 | 30 |

| 2.4 | +/-0.03 | 1270 | 25 | 11 | 30 |

| 2.6 | +/-0.03 | 1270 | 25 | 10 | 35 |

| 2.77 | +/-0.03 | 1270 | 25 | 9 | 35 |

Production Flow Chart

Project Case

Pack And Ship

Certificate

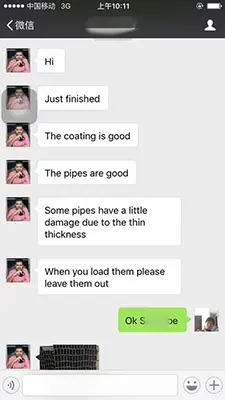

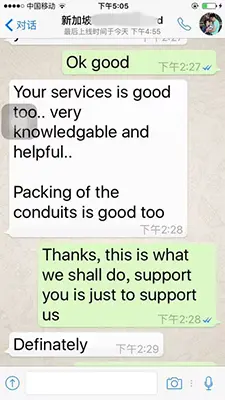

Customer Praise

Plant And Equipment

FAQ

1.Are you trader or manufacturer?

We are professional manufacturer of steel processing and galvanizing,owing our own galvanizing mill with first class.

2.Is personalized steel processing services available for customer?

Yes,get in touch with us and we will be happy to discuss your requirements in depth and our highly trained team members will ensure that the completed service meets all your requirements.

3.What is your regular delivery time?

It will be 5-7 days,it will depend on your exact order quantity.

4.Is free sample available for customer?

Yes,we will send customer free samples,and the freight charge will be paid by customers.

5.How do you control your quality of products?

We will do sampling and full inspection from raw materials to finished products.

2.Is personalized steel processing services available for customer?

Yes,get in touch with us and we will be happy to discuss your requirements in depth and our highly trained team members will ensure that the completed service meets all your requirements.

3.What is your regular delivery time?

It will be 5-7 days,it will depend on your exact order quantity.

4.Is free sample available for customer?

Yes,we will send customer free samples,and the freight charge will be paid by customers.

5.How do you control your quality of products?

We will do sampling and full inspection from raw materials to finished products.

Leave Your Message

This is a paragraph