When embarking on a new project, one crucial element to consider is the choice of materials, specifically the type of plate sheet that will best suit your needs. Plate sheets are versatile components used across various industries, from construction to manufacturing, due to their robust properties and adaptability. Selecting the right plate sheet can significantly impact the overall quality and durability of your project, making it essential to understand the available options.

In this guide, we will explore the top ten best plate sheet choices that you can incorporate into your upcoming project. Whether you're seeking lightweight materials for ease of handling or robust options for heavy-duty applications, our selection covers a range of characteristics, including thickness, material composition, and finish. Understanding these factors will not only enhance the functionality of your project but also ensure that you achieve the desired aesthetic and performance outcomes. As we delve into these options, you'll gain valuable insights that will equip you with the knowledge to make informed decisions about the ideal plate sheet for your specific requirements.

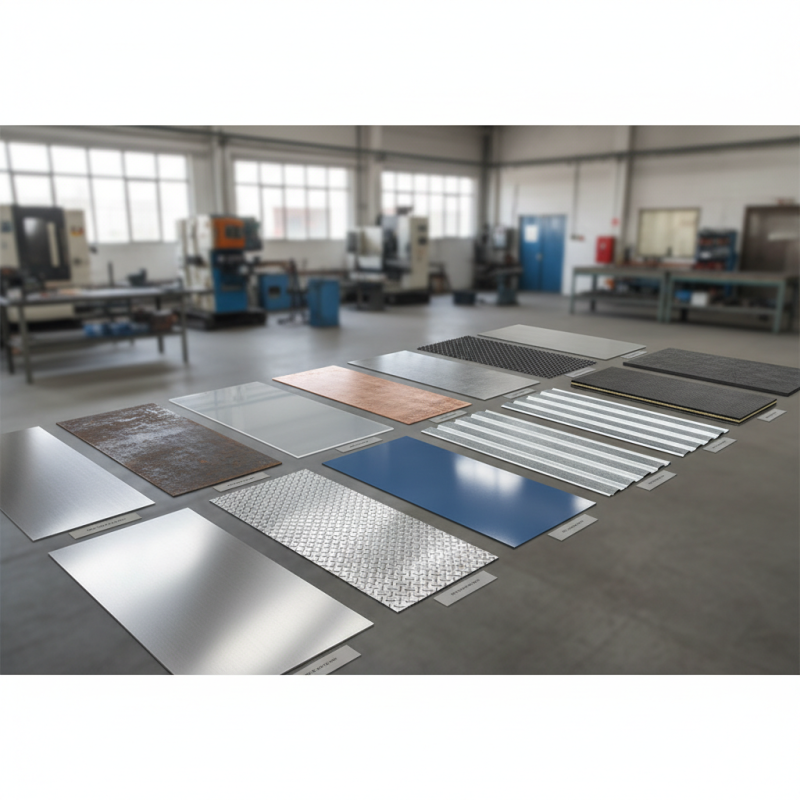

Plate sheets are flat and typically rectangular materials that come in various thicknesses and sizes, primarily made from metals like steel, aluminum, and composite materials. These sheets are known for their strength and durability, making them integral to a wide range of industrial and construction applications. They are commonly used in manufacturing structural components, machinery, and equipment enclosures, as well as in construction for beams, columns, and flooring systems.

In addition to structural uses, plate sheets also find application in creative fields such as art and design, where they serve as canvases for sculptures and installations. Their versatility allows them to be cut, shaped, and welded, opening up possibilities for custom projects. Moreover, plate sheets are used in automotive and aerospace industries, where precise engineering and weight considerations are critical. The ability to withstand high stress and impact means they are ideal for ensuring safety and reliability in various applications.

| Plate Sheet Type | Material | Thickness (mm) | Common Uses | Weight (kg/m²) |

|---|---|---|---|---|

| Aluminum Plate | Aluminum | 3 | Aerospace, Automotive | 7.85 |

| Carbon Steel Plate | Steel | 4 | Construction, Shipbuilding | 7.85 |

| Stainless Steel Plate | Stainless Steel | 5 | Food Processing, Medical Equipment | 7.93 |

| Titanium Plate | Titanium | 6 | Aerospace, Marine | 4.51 |

| Copper Plate | Copper | 2 | Electrical, Plumbing | 8.96 |

| Plastic Sheet | Polycarbonate | 8 | Signage, Protective Barriers | 1.2 |

| Lead Sheet | Lead | 10 | Radiation Shielding | 11.34 |

| Fiber Reinforced Plastic Sheet | Composite | 5 | Automobile Components, Aerospace | 3.2 |

| Glass Fiber Reinforced Plastic Sheet | Composite | 4 | Transportation, Roofing | 2.5 |

| Wood Composite Sheet | Wood | 18 | Furniture, Flooring | 6.0 |

When selecting plate sheet materials for your project, several critical factors must be evaluated to ensure you make the most informed choice. First and foremost, consider the material's mechanical properties, including strength, durability, and flexibility. Depending on the intended application, you may require sheets that can withstand significant stress or those with high impact resistance. Understanding the specific demands of your project will help in identifying the most suitable materials.

Another essential consideration is the environmental conditions to which the plate sheets will be exposed. Factors such as moisture, temperature fluctuations, and chemical exposure can influence the longevity and performance of the material. For instance, if the sheets will be utilized in an outdoor setting, corrosion resistance may become a top priority. Additionally, it’s important to think about the weight of the material, as heavier sheets may complicate installation and transportation processes. By balancing these considerations, you can choose the ideal plate sheet that meets both functional requirements and project specifications.

When selecting the right plate sheet for your next project, understanding the features and benefits of various options is essential. Plate sheets come in diverse materials, including aluminum, steel, and composite options, each offering unique advantages. Aluminum sheets are not only lightweight but also resistant to corrosion, making them suitable for outdoor applications. Steel plates, on the other hand, provide exceptional strength and durability, ideal for heavy-duty tasks. Composite sheets combine the best qualities of different materials, offering high strength-to-weight ratios and thermal insulation.

Tips for choosing the right plate sheet include assessing the specific requirements of your project. Consider factors like weight, strength, and environmental exposure. For example, if you need a sheet that withstands harsh weather conditions, prioritize materials with higher resistance levels. Additionally, evaluate the ease of installation and maintenance; some materials may require special tools or techniques for cutting and fitting. By aligning these features with your project needs, you can optimize performance and longevity.

Another essential aspect is cost-effectiveness. While premium materials may offer advanced benefits, balancing your budget without compromising on quality is crucial. Research different suppliers to compare prices while ensuring that the selected plates meet safety and performance standards. Staying informed about innovations in materials can also provide additional options that may enhance your project’s efficacy.

Plate sheets are versatile materials widely used across various industries due to their durability, strength, and adaptability. In construction, plate sheets serve as essential components for structural support, flooring, and roofing systems. Their ability to withstand heavy loads and harsh conditions makes them ideal for foundations and framing. In the automotive industry, plate sheets are utilized for body panels and components, offering a lightweight solution that maintains structural integrity while enhancing fuel efficiency.

When incorporating plate sheets into your next project, consider the material properties that best meet your needs. For instance, choosing the right thickness can significantly affect durability and weight distribution. Additionally, exploring coatings and treatments can improve resistance to corrosion and wear, extending the lifespan of your project.

As you dive into your applications, utilize our tips for optimizing plate sheet performance. Always assess the environmental conditions the sheets will face—like exposure to harsh weather or chemicals—and select materials accordingly. Finally, ensure accurate measurements and cuts to minimize waste and enhance the precision of your assembly process. This attention to detail will lead to improved outcomes in your projects, regardless of the industry.

When it comes to maintaining plate sheets in any project, a systematic approach to care is essential for ensuring longevity and performance. According to a report by the American Welding Society, improper care of metal sheets can lead to significant corrosion, which impacts structural integrity and overall cost. Regular inspection and cleaning are vital; using non-corrosive cleaners helps eliminate contaminants without damaging the surface. Implementing a routine maintenance schedule can reduce deterioration by up to 30%, which is crucial for projects that involve heavy usage or exposure to harsh environments.

Environmental factors also play a significant role in the longevity of plate sheets. The National Association of Corrosion Engineers states that moisture, pollutants, and temperature fluctuations can accelerate wear. Therefore, applying protective coatings can act as a barrier against these elements. Additionally, storing plate sheets in a controlled environment reduces the risk of oxidation and physical damage. It is advisable to keep them in a dry location, ideally with humidity levels below 50%. By focusing on these maintenance and care practices, you can significantly enhance the lifespan and performance of your plate sheets in any project.