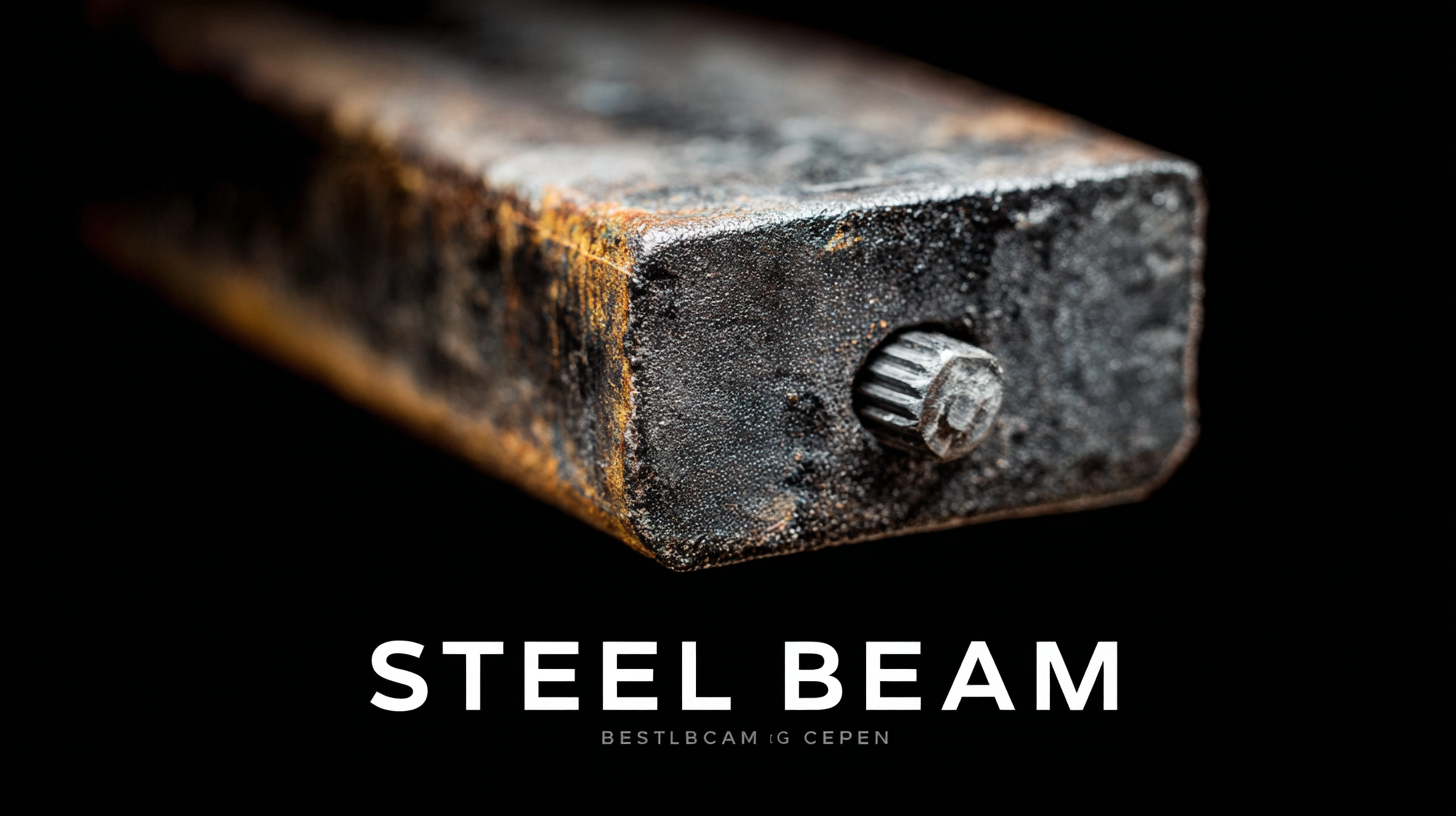

In the competitive landscape of construction and structural engineering, the choice of materials plays a crucial role in determining the overall success of projects. Among these materials, the steel beam stands out for its strength, durability, and cost efficiency. According to a report by the American Institute of Steel Construction (AISC), steel beams can reduce construction costs by up to 10% compared to traditional materials, while providing a lifespan that exceeds 50 years with minimal maintenance. Additionally, the World Steel Association reports that the global demand for structural steel is projected to grow by 5% annually, reflecting the material's increasing popularity among global buyers. In this blog, we will delve into a comprehensive comparison of steel beams, highlighting their performance metrics, cost considerations, and sustainable benefits, equipping readers with valuable insights for informed decision-making in their construction projects.

When selecting steel beams for construction projects, understanding the various types available is crucial for ensuring structural integrity and cost-effectiveness. The most common types of steel beams include

I-beams, H-beams, and C-channel beams.

I-beams are widely used due to their excellent load-bearing capacity and stability, making them ideal for constructions that require significant strength.

H-beams, on the other hand, offer a wider flange and greater resistance to twisting, which can be advantageous in high-stress applications.

Additionally, C-channel beams provide versatility in construction, often utilized in lighter structural applications and as support for various installations.

Each type has unique properties that cater to different structural requirements, from weight distribution and span length to resistance to bending. By understanding these differences, buyers can make informed decisions that align with their project specifications and budget constraints, ultimately ensuring the selection of the most suitable steel beam type for their needs.

When choosing the right steel beam for your project, evaluating strength is paramount. Recent studies, such as those utilizing machine learning techniques, have demonstrated an ability to assess the shear strength of corroded reinforced concrete beams with impressive accuracy. This provides valuable insights for structural engineers who need to ensure that the steel beams they select can withstand specific stresses and loads.

Emerging trends highlight the significance of using various steel fibers to enhance the shear strength of reinforced slender beams. Research has shown that different types of steel fibers, including straight wire and deformed wire, can substantially improve performance metrics when integrated into concrete structures. This advancement, combined with a growing emphasis on sustainable building materials, points to an exciting future where technological innovations lead to enhanced performance and cost efficiency.

**Tip 1:** Always consider the environment in which your steel beam will be placed; factors such as corrosion resistance are vital for longevity.

**Tip 2:** Analyze the specific load requirements of your project to match with the shear strength capabilities of different steel beam options.

**Tip 3:** Stay informed on the latest advancements in materials science, as innovations like steel fibers can significantly impact the structural integrity of your construction.

When it comes to construction, the choice of materials can significantly impact a project’s longevity and overall success.

High-quality steel beams stand out for their exceptional durability, making them a top choice for both residential and commercial applications.

Unlike other materials, steel beams resist warping, cracking, and environmental wear, ensuring that structures remain stable over time.

This resilience not only reduces maintenance costs but also extends the life of the project.

Tips for Choosing Durable Steel Beams:

When considering the purchase of steel beams, understanding cost efficiency is paramount. The upfront price of steel beams can vary widely based on factors like quality, size, and manufacturer. However, buyers should also evaluate the long-term savings associated with durability and maintenance. High-quality steel beams, though initially more expensive, can reduce repair costs and enhance longevity, providing a better return on investment over time.

When considering the purchase of steel beams, understanding cost efficiency is paramount. The upfront price of steel beams can vary widely based on factors like quality, size, and manufacturer. However, buyers should also evaluate the long-term savings associated with durability and maintenance. High-quality steel beams, though initially more expensive, can reduce repair costs and enhance longevity, providing a better return on investment over time.

Tip: Always factor in the total lifecycle cost of steel beams, not just the purchase price. Look for suppliers that offer warranties or guarantees, which can provide additional peace of mind and protect your investment.

Moreover, steel beams are renowned for their strength-to-weight ratio, allowing for more efficient designs that save on material costs and labor during installation. This efficiency can translate into significant savings, especially for large-scale projects.

Tip: When selecting steel beams, consult with engineers for optimal designs that utilize materials effectively. This collaboration can uncover cost-saving opportunities that might be overlooked, maximizing both functionality and value.

China has established itself as a dominant player in the global steel beam manufacturing market, thanks to its robust industrial infrastructure and cost-effective production processes. With state-of-the-art facilities and advanced technologies, Chinese manufacturers are capable of producing a wide variety of steel beams that meet diverse needs and specifications. This enables global buyers to access high-quality products at competitive prices, which is crucial for projects that require both durability and financial efficiency.

Moreover, China's strategic investments in research and development have led to significant improvements in the strength and reliability of steel beams. The country's focus on sustainable practices and innovative methods ensures that the materials produced are not only strong but also environmentally friendly. As a result, sourcing steel beams from China offers international buyers not only cost savings but also peace of mind in terms of product quality and compliance with international standards.

These advantages position China as a preferred partner for businesses looking to optimize their supply chains while ensuring that structural integrity is never compromised.