When it comes to manufacturing, selecting the right materials is crucial for ensuring both quality and efficiency in production processes. Among these materials, the "Metal Steel Sheet" stands out as a versatile and essential component used across various industries, from automotive to construction. However, with a myriad of options available in the market, choosing the best metal steel sheet for your specific manufacturing needs can be a daunting task. Factors such as thickness, finish, strength, and resistance to corrosion play pivotal roles in determining which type of metal steel sheet will best suit your project requirements. In this blog, we will guide you through the critical considerations and factors to keep in mind so that you can make informed decisions and ultimately select the optimal metal steel sheet tailored to your operational demands.

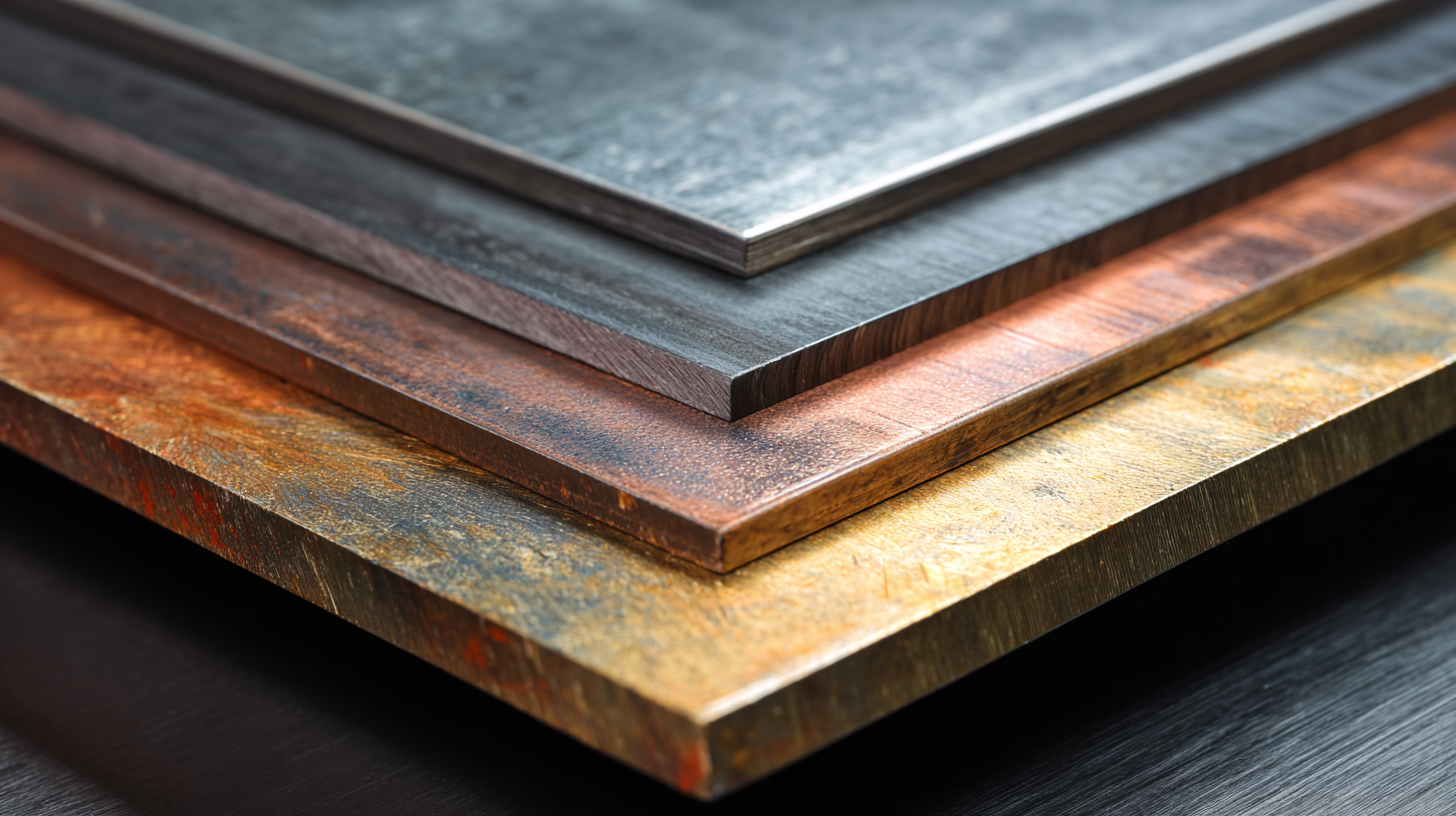

When selecting the best metal steel sheet for your manufacturing needs, it's essential to understand the different types available in the market. Steel sheets come in various grades and styles, tailored for specific applications, particularly in industries like automotive and construction. For instance, advancements in lightweight composite structures and manufacturing technologies underscore the significance of selecting steel alloys that offer the right balance of strength and weight. As the global sheet metal market is projected to reach $450 billion by 2033, with an estimated CAGR of 4%, the demand for specialized steel sheets continues to grow.

Tips for choosing the right steel sheet include evaluating corrosion resistance, which is crucial for durability in structures and components. Recent studies have highlighted the effectiveness of hot-dip galvanized steel coatings in automotive and rail applications, ensuring longer life spans for your products. Additionally, consider the forming limits of different steel grades—research utilizing ANFIS-based predictions indicates that understanding material properties can significantly impact the success of your manufacturing processes. By keeping these points in mind, you can make informed decisions that align with your operational goals.

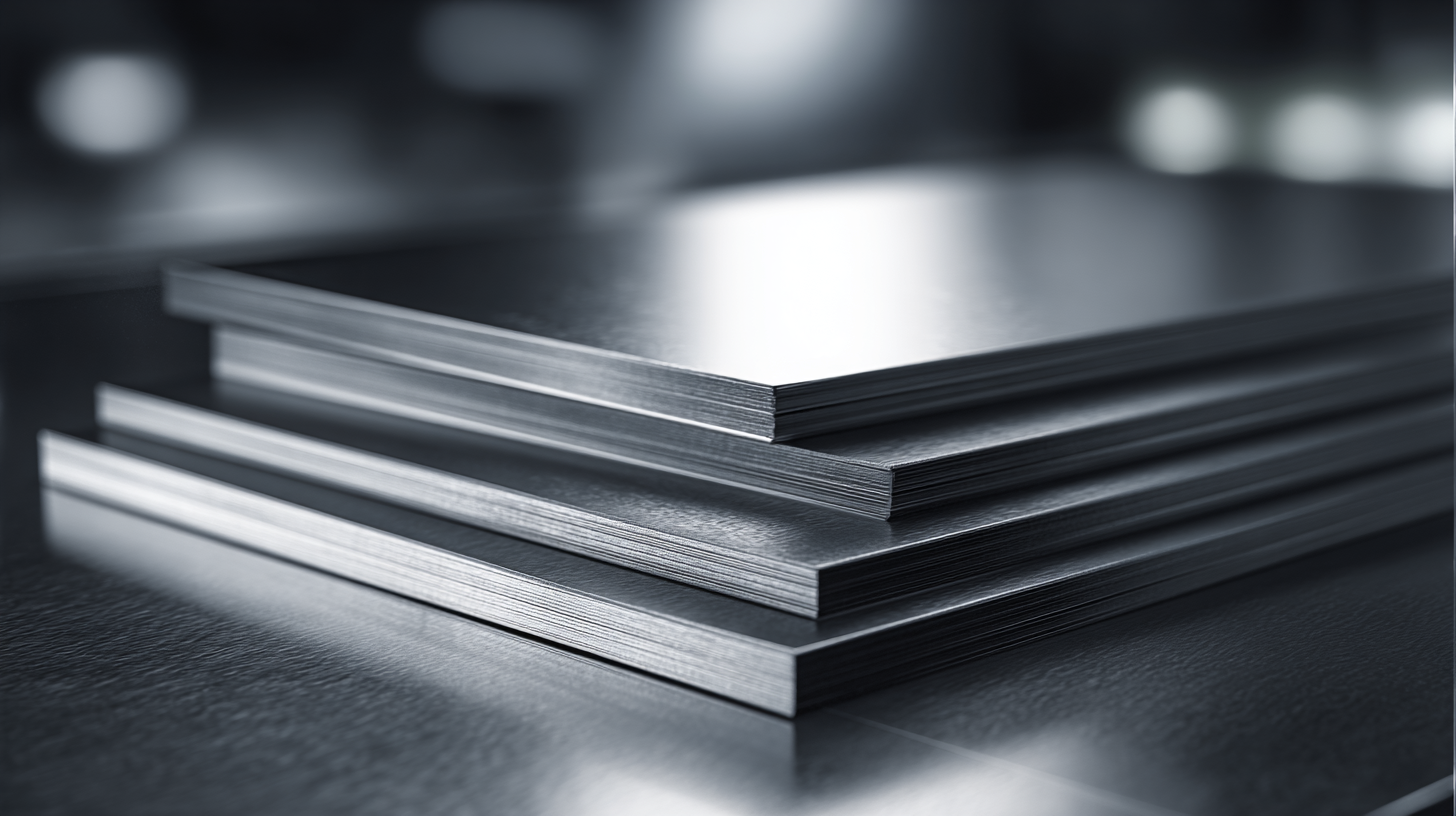

When selecting metal steel sheets for manufacturing, several key properties must be considered to ensure optimal performance for your specific application. First and foremost, you should evaluate the steel grade. Different grades of steel offer varying levels of strength, ductility, and resistance to corrosion or wear. For instance, stainless steel is ideal for applications requiring high corrosion resistance, while carbon steel may be more suitable for projects focusing on strength and durability.

Another critical property to consider is thickness. The thickness of the steel sheet directly impacts its strength and ability to withstand forces. Thicker sheets are generally more robust but can also be heavier and more expensive. Additionally, it’s essential to assess the sheet’s surface finish and coating options. A smooth finish can enhance aesthetic appeal and functionality, while coatings can provide additional protection against environmental factors. By carefully considering these properties, you can select the best metal steel sheet that aligns with your manufacturing needs, ensuring product quality and longevity.

Metal steel sheets play a crucial role in various manufacturing sectors due to their versatility and strength. They are commonly used in automotive, construction, and appliance manufacturing, where durability and precision are paramount. According to a recent report by Smithers Pira, the global metal sheet market is expected to reach $300 billion by 2025, highlighting the increasing demand for high-quality steel sheets across industries.

When selecting a metal steel sheet, it's essential to consider the specific applications. For instance, automotive manufacturers often require sheets with high tensile strength and corrosion resistance to ensure vehicle longevity. In the construction industry, galvanized steel sheets are favored for their ability to withstand harsh weather conditions while maintaining structural integrity. It's advisable to consult with material engineers to determine the best grade of steel for your specific project needs.

**Tip:** Always analyze the mechanical properties required for your application, such as hardness and ductility, before making a purchase. **Tip:** Consider the processing methods—like welding and cutting—when selecting a steel sheet, as these can influence the overall production efficiency. Understanding these factors can lead to better material selection and improved end products.

When selecting the best metal steel sheet for manufacturing purposes, it is crucial to evaluate the cost versus quality of the materials available. The initial price of steel sheets may seem appealing, but if the quality is subpar, it can lead to increased expenses in the long run due to high failure rates, maintenance costs, or premature replacements. Therefore, striking a balance between budget constraints and material durability is key. Manufacturers should consider the specific requirements of their projects, such as tensile strength, corrosion resistance, and formability, as these factors directly impact the overall performance and longevity of the steel sheet.

Investing in higher quality steel sheets often pays off, especially for applications that demand precision and reliability. In many instances, opting for a trusted supplier that offers a warranty or quality assurance can mitigate risks associated with lower-cost alternatives. Furthermore, engaging in thorough research, including reviews and case studies, can help manufacturers make informed choices. By understanding the long-term implications of their selection, businesses can prioritize quality over the immediate allure of cheaper options, ultimately leading to greater productivity and cost-effectiveness in their operations.

When sourcing metal steel sheets for your manufacturing needs, it's crucial to partner with reliable suppliers to ensure quality and adherence to specifications. In light of recent tariff developments, which have created an unpredictable market environment, a strategic approach to sourcing is imperative.

One of the first tips is to prioritize suppliers who provide transparency about their sourcing practices and compliance with trade regulations. With the implementation of tariffs on metal imports, understanding the origins of your materials can help navigate potential cost increases and supply chain disruptions.

Additionally, consider suppliers who offer customizable solutions tailored to your specific needs. This flexibility can be a significant advantage in maximizing the utility of the metal sheets while minimizing waste. Look for manufacturers with a strong track record in quality assurance and customer service, as this will contribute to a smoother procurement process amidst fluctuating market conditions.