In the construction industry, selecting the appropriate materials is pivotal for the success and longevity of any project. Among various material options, "Steel Frames" have gained significant traction due to their strength, durability, and versatility. According to a report from the World Steel Association, the global demand for steel in construction is forecasted to reach approximately 1.6 billion tons by 2025, highlighting the increasing reliance on steel frameworks in modern architecture. As we recognize the burgeoning trend towards sustainable practices, steel’s recyclability reinforces its position as a choice material for eco-conscious projects.

Industry expert Dr. Emily Johnson, a prominent figure in civil engineering, emphasizes the importance of making informed decisions regarding structural components. She states, “The choice of steel frames can drastically influence the overall performance and sustainability of a building.” This sentiment reflects a broader acknowledgment within the industry that the selection process must consider not only the project's immediate needs but also long-term implications such as maintenance, lifecycle costs, and environmental impact. As construction practices evolve, understanding the nuances of different steel framing options becomes essential for architects and builders alike, ensuring they are well-equipped to meet the demands of contemporary construction challenges.

When selecting the right steel frames for a construction project, understanding the different types available is crucial. Steel frames can be broadly categorized into several types, including structural steel frames, cold-formed steel frames, and modular steel frames. Structural steel frames are known for their strength and durability, making them ideal for high-rise buildings and large industrial projects. These frames are constructed using steel beams and columns, providing a solid foundation that can withstand significant loads and environmental stresses.

Cold-formed steel frames, on the other hand, are manufactured from thin sheets of steel that are shaped at room temperature. They are lightweight and often used in residential and low-rise commercial buildings. This type of frame allows for a quick construction process and is perfect for projects that require flexibility and ease of installation. Finally, modular steel frames combine pre-fabricated modules, which are manufactured off-site and then assembled on-site. This method can speed up construction time and can be especially useful in tight urban environments where space is limited. Each type of steel frame offers distinct advantages, making it essential to consider the specific requirements of your construction project when making a choice.

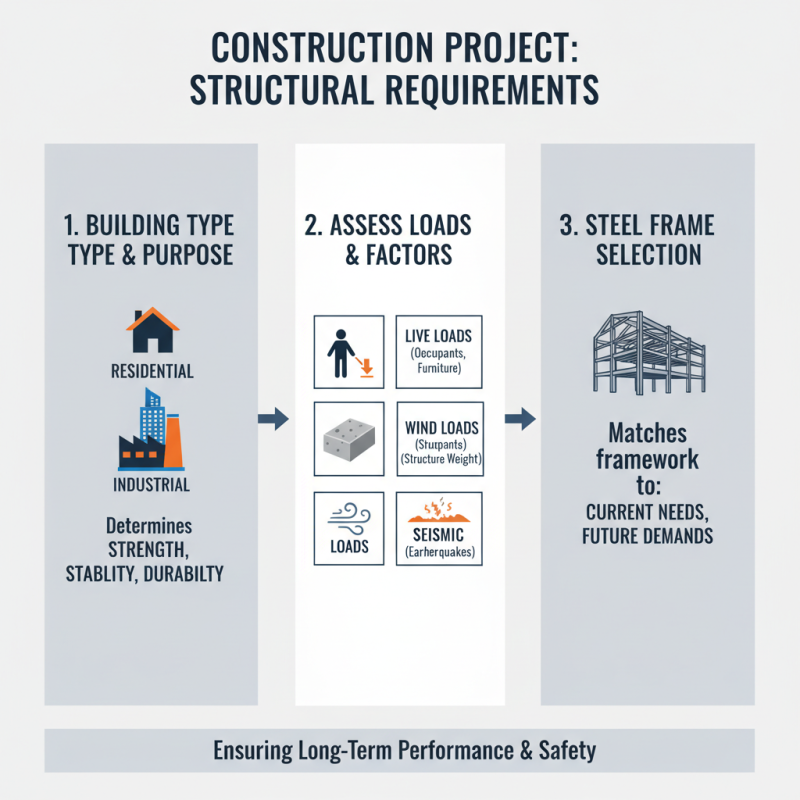

When evaluating the structural requirements of your construction project, it is essential to consider the type and purpose of the building. Different structures, whether residential, commercial, or industrial, demand varying levels of strength, stability, and durability. Begin by assessing the anticipated loads, including live loads, dead loads, wind loads, and seismic factors. This comprehensive understanding will inform the selection of suitable steel frame configurations, ensuring that the framework can accommodate not only current needs but also future demands.

Moreover, the environmental conditions of the construction site play a critical role in material selection. Factors such as climate, local soil conditions, and exposure to corrosive elements can significantly impact the longevity and performance of steel frames. It is vital to analyze these conditions and choose steel grades and protective coatings that enhance resilience. By meticulously examining these structural requirements, you can make informed decisions that align with both safety standards and design aesthetics, ensuring a robust and enduring construction project.

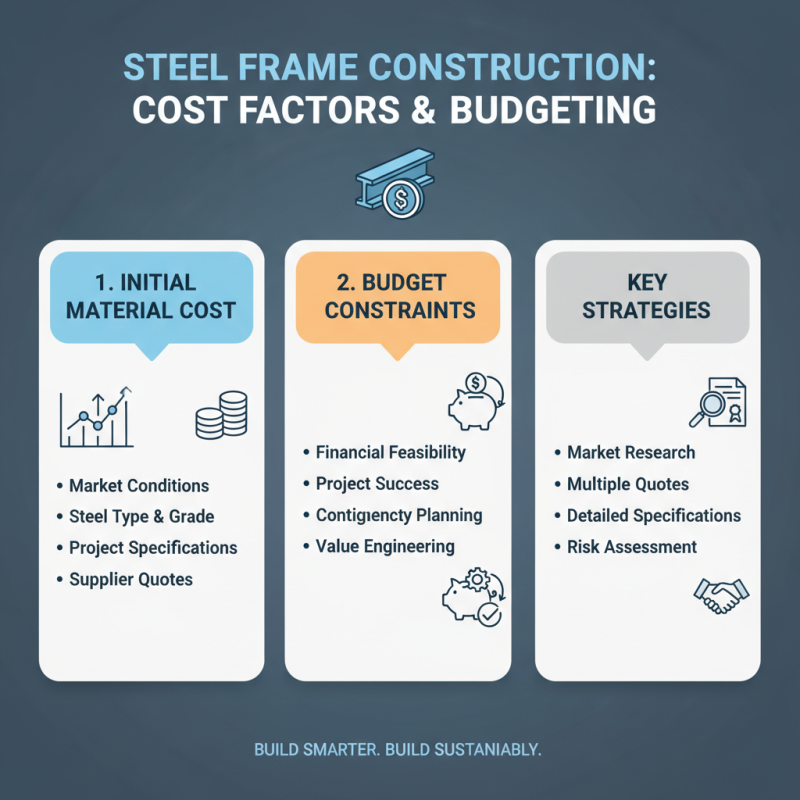

When embarking on a construction project, assessing cost factors and budget constraints for steel frames is crucial to ensure financial feasibility and project success. One of the primary considerations is the initial cost of materials. Steel frame prices can vary significantly depending on market conditions, the type of steel, and the specifications required for your project. It is essential to conduct thorough market research and obtain multiple quotes from suppliers to understand the price spectrum.

Another vital aspect to consider is the long-term costs associated with maintenance and durability. Steel frames are known for their strength and longevity, which can result in lower maintenance expenses over time. However, it’s important to factor in any potential costs linked to corrosion treatment or protective coatings, especially in environments prone to moisture. Furthermore, transportation, labor, and installation costs should also be included in the overall budget, as these factors can have a substantial impact on the total expenditure of the project. By carefully evaluating these cost elements, you can make informed decisions that align with your financial objectives while ensuring the structural integrity of your construction.

When selecting steel frames for a construction project, considering environmental impact and sustainability is paramount. The production of steel is known to contribute significantly to carbon emissions; however, advancements in eco-friendly steel production techniques have emerged as crucial solutions. According to the World Steel Association, steel is one of the most recycled materials globally, with approximately 85% of structural steel being recycled at the end of its life cycle. This not only reduces the demand for raw materials but also minimizes energy consumption associated with new steel production.

Tips for sustainable steel selection involve choosing recycled steel or low-carbon options, which drastically reduce the construction project's carbon footprint. Additionally, it is essential to look at the entire supply chain for eco-friendly practices. Consideration of local sourcing can further minimize transportation emissions and support the local economy. Moreover, evaluating the durability and lifespan of steel elements can also contribute to sustainability, as longer-lasting materials reduce the frequency of replacements and associated waste.

Incorporating life-cycle assessments in decision-making processes allows builders to measure the environmental impact of steel throughout its entire lifespan, from production to disposal. Reports from industry leaders indicate that steel structures designed with sustainability in mind not only benefit the environment but often provide cost savings over time due to lower energy usage and less frequent repairs. By prioritizing environmentally responsible choices, construction projects can significantly enhance their overall sustainability profile.

When embarking on a construction project, one of the crucial decisions revolves around selecting between prefabricated and custom-built steel frames. Prefabricated steel frames offer a streamlined construction process, as they are manufactured off-site and delivered ready for assembly. This can significantly reduce construction time and labor costs, making them an attractive option for projects with tight deadlines. Additionally, prefabricated frames are often built to standardized specifications, which can simplify project planning and increase overall efficiency.

On the other hand, custom-built steel frames allow for greater flexibility and design creativity. They can be tailored to meet specific architectural requirements, ensuring that the structure aligns perfectly with the project's vision. This option is particularly beneficial for unique or complex designs where standard solutions may not suffice. However, custom-built frames can involve longer lead times and potentially higher costs due to the need for specialized design and manufacturing processes. Ultimately, the choice between prefabricated and custom-built steel frames should be based on project demands, budget, and timeline considerations, ensuring that the selected option supports the overall goals of the construction project.