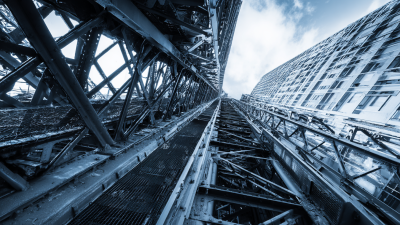

When it comes to construction and structural design, selecting the right materials is crucial for ensuring safety, durability, and efficiency. Among the various options available, Steel Section stands out as a popular choice due to its strength and versatility. However, with numerous steel types and specifications on the market, making an informed decision can be daunting. This essential Steel Section checklist aims to guide you through the key factors to consider when choosing the right materials for your project. From understanding the different types and their applications to evaluating their properties and performance, our comprehensive overview will equip you with the knowledge needed to select the optimal steel sections that meet your structural requirements. Whether you are an engineer, architect, or builder, mastering these elements will help you achieve both functional and aesthetic goals in your construction endeavors.

When selecting steel sections for construction projects, three key considerations often guide the decision-making process: weight, durability, and cost efficiency. According to a report by the American Institute of Steel Construction (AISC), the weight of steel sections directly influences structural load and design efficiency. Lighter steel sections can lead to reduced foundation costs, saving up to 20% on overall material expenditures, especially in large-scale constructions where material weight is critical.

Durability is another crucial factor. A study published in the journal "Materials Science" revealed that weathering steel, which offers enhanced corrosion resistance, can extend the lifespan of structures by over 30 years compared to traditional grades. This characteristic not only ensures safety and reliability but also minimizes long-term maintenance costs, reinforcing the financial viability of opting for more durable materials upfront.

Lastly, cost efficiency encompasses not just the initial purchase price but also the lifecycle costs of steel sections. The World Steel Association reports that adopting high-strength steel can reduce material usage by up to 40%, further decreasing manufacturing and transportation expenses. By factoring in these elements, stakeholders can make informed decisions that balance immediate budget constraints with long-term project sustainability.

When selecting the appropriate steel materials for construction or manufacturing projects, understanding the various steel grades and their material properties is essential. Different grades of steel possess unique characteristics, such as tensile strength, ductility, and corrosion resistance, which can significantly influence the success of a project. For example, high-strength steel grades are ideal for structures requiring resilience under heavy loads, while stainless steel grades are optimal in environments prone to corrosion.

Moreover, the advancement of technologies such as Additive Manufacturing is changing the landscape of steel production. By employing innovative methodologies, companies can tailor the properties of steel to meet specific project requirements. This trend not only enhances performance but also promotes sustainability in building materials through custom fabrication and reduced waste. In parallel, research initiatives focused on alternative solutions, like replacing traditional chemicals with environmentally friendly options, highlight the ongoing evolution in material science. Thus, careful consideration of steel grades and their properties is fundamental to achieving project success while embracing modern advancements.

This bar chart represents various steel grades and their tensile strength, yield strength, and elongation properties. Understanding these material properties can significantly influence project success by ensuring the right steel is chosen for specific applications.

When selecting steel materials, sustainability is a crucial factor that can no longer be overlooked. As the construction industry grapples with its environmental footprint, evaluating the ecological impact of steel is essential. According to a report by the World Steel Association, the steel industry accounts for approximately 7% of global carbon emissions. This statistic underscores the urgency of choosing steel that minimizes these emissions, through practices like using electric arc furnace (EAF) technology, which can reduce carbon emissions by up to 75% compared to traditional blast furnaces.

In addition to production methods, the lifecycle assessment of steel materials plays a vital role in sustainability efforts. Studies show that steel is one of the most recycled materials globally, with the recycling rate exceeding 85% in many regions. This not only conserves resources but also significantly reduces energy consumption—recycling steel saves about 74% energy compared to producing new steel from raw materials. As architects and builders aim to meet greener standards, selecting sustainably sourced steel that emphasizes recyclability and lower emissions should be at the forefront of their material choices.

When it comes to structural design, load-bearing capacities play a pivotal role in determining the suitability of steel sections. According to the American Institute of Steel Construction (AISC), properly evaluating the load-bearing capabilities of materials can significantly enhance the safety and longevity of structures. For instance, hot-rolled steel sections, such as I-beams and H-columns, typically exhibit higher yield strengths, often surpassing 35 ksi (kilopounds per square inch), which allows them to withstand greater forces without failure. Understanding these parameters is vital for engineers in selecting the right materials that not only meet the design requirements but also optimize performance under various loading conditions.

Research from the International Institute of Welding (IIW) highlights that the load-bearing capacity is affected by factors such as the moment of inertia and the geometry of the steel section. Specifically, a wider flange can reduce bending stresses, thus increasing overall stability. Additionally, it has been reported that utilizing high-strength structural steels can result in a 20-30% reduction in material usage while maintaining the necessary safety factors, leading to more sustainable construction practices. These insights underline the importance of quantifying load-bearing capacities in the selection process, ensuring that structural designs are both efficient and robust.

In the ever-evolving steel industry, staying informed about key trends and market demands is crucial for businesses seeking to make well-informed decisions. Recent analyses indicate a growing emphasis on the use of sustainable materials, enhanced efficiency in production processes, and resilience against market fluctuations. The global steel market remains robust, with notable growth projections, particularly in sectors utilizing innovative steel sections for construction and manufacturing.

Tips for Selecting the Right Steel Sections:

When choosing steel sections, it's essential to assess both your immediate and future needs. Consider factors such as the material's strength, durability, and compatibility with other components in your projects. Additionally, evaluate the current trends in steel usage – for instance, increasing demand for eco-friendly and recycled materials can influence your choices. Monitoring market developments and technological advancements will further aid in selecting the most suitable products for your applications.

Another vital point is to engage with reputable suppliers who can offer insights into the latest market trends and product innovations. Building long-term partnerships not only enhances supply chain reliability but also grants you access to expert advice that can lead to smarter purchasing decisions. Always prioritize suppliers who demonstrate a commitment to quality and sustainability, aligning with the overarching trends in steel section usage and market analysis.