The construction industry is undergoing a significant transformation with the advent of innovative materials, particularly "Material Steel." According to a report by the World Steel Association, global steel production reached approximately 1.9 billion tonnes in 2020 and is projected to grow at an annual rate of 1.5% through 2025. This growth is spurred by advancements in material technology, which enhance the strength, durability, and sustainability of steel products. Innovations such as high-strength steel and metallic coatings are redefining fabrication processes and permitting the construction of lighter and more resilient structures. Additionally, the shift towards eco-friendly practices has prompted the development of recyclable steel solutions, aligning with global sustainability goals. As we explore the future of material steel innovations, it becomes evident that these advancements are essential for achieving efficiency, reducing waste, and meeting the increasing demands of modern construction projects.

Innovative steel alloys are revolutionizing the construction industry by significantly enhancing the strength and durability of structures. According to a report by the World Steel Association, steel usage is projected to reach over 1.8 billion tons by 2025, with advanced alloys playing a crucial role in this growth. These new formulations allow for lighter yet stronger materials, enabling architects and engineers to design more resilient buildings that withstand both environmental pressures and increasing loads.

Innovative steel alloys are revolutionizing the construction industry by significantly enhancing the strength and durability of structures. According to a report by the World Steel Association, steel usage is projected to reach over 1.8 billion tons by 2025, with advanced alloys playing a crucial role in this growth. These new formulations allow for lighter yet stronger materials, enabling architects and engineers to design more resilient buildings that withstand both environmental pressures and increasing loads.

Furthermore, recent studies indicate that the implementation of high-performance steel alloys can reduce the overall lifecycle costs of construction projects. The Global Institute of Steel Innovations highlights that such materials not only decrease the need for frequent repairs and replacements but also enhance energy efficiency during construction. For example, ultra-high-performance concrete combined with advanced steel alloys has shown to exceed traditional strength benchmarks by up to 40%, presenting a formidable option for modern construction demands. As the demand for sustainable and durable materials rises, innovative steel alloys may very well define the future of building and fabrication.

The future of construction and fabrication is increasingly tied to advancements in steel technologies that streamline processes and enhance efficiency. Recent developments highlight a significant shift towards automation and innovative fabrication methods. For instance, the Saudi Arabian rebar steel market is projected to grow to $11.9 billion by 2025, driven by rapid urbanization and population growth, demonstrating the rising demand for advanced steel solutions in infrastructure. These economic trends indicate a strong correlation between construction demand and the evolution of steel technologies.

Companies are also adopting cutting-edge practices in their operations. The launch of new facilities, such as a 147,500 square foot steel fabrication plant dedicated to advanced processes, showcases the industry's commitment to modernizing production capabilities. Furthermore, events like Metal Expo Istanbul 2025 will unveil innovations in steel processing that should enhance production efficiency and quality control. As automation increasingly integrates into both the construction and biopharmaceutical sectors, organizations are poised to benefit significantly from streamlined workflows and reduced operational dependencies on labor-intensive practices.

These advancements signify a transformative era for material steel innovations, with far-reaching implications for the construction landscape.

The construction industry is undergoing a significant transformation, driven by the need for sustainable practices and eco-friendly innovations. Recent studies indicate that steel production accounts for approximately 7-9% of global carbon emissions, compelling manufacturers to explore greener alternatives. For instance, the World Steel Association reports that the use of recycled steel can reduce CO2 emissions by up to 75% compared to producing new steel. Innovations such as electric arc furnaces, which utilize scrap steel and renewable energy sources, are leading the charge toward a more sustainable future.

Moreover, advancements in steel technologies, like the development of low-carbon steel, are making a notable impact in construction and fabrication. According to a 2022 report by the European Commission, implementing low-carbon steel within the industry could potentially cut emissions by over 30 million tons annually in Europe alone. This shift towards sustainable materials not only decreases the environmental footprint but also enhances the longevity and performance of structures. By embracing these innovations, the construction industry can align itself with global sustainability goals while ensuring the integrity and resilience of future building projects.

| Innovation Type | Description | Benefits | Implementation Status | Projected Impact (2025) |

|---|---|---|---|---|

| Recycled Steel | Steel made from recycled materials. | Reduces waste and conserves resources. | Widespread | 50% of steel products |

| Corrosion-Resistant Steel | Steel treated for enhanced durability. | Longer lifespan, reduced maintenance costs. | Increasing Adoption | 30% market penetration |

| Smart Steel | Steel integrated with sensors for monitoring. | Improved safety and maintenance. | Pilot Projects | 20% implementation in major projects |

| Biodegradable Coatings | Eco-friendly coatings for steel products. | Lessened environmental impact after disposal. | Research Phase | 10% expected use |

| Low Carbon Steel | Steel produced with significantly lower emissions. | Reduced carbon footprint and environmental impact. | In Development | 25% market presence |

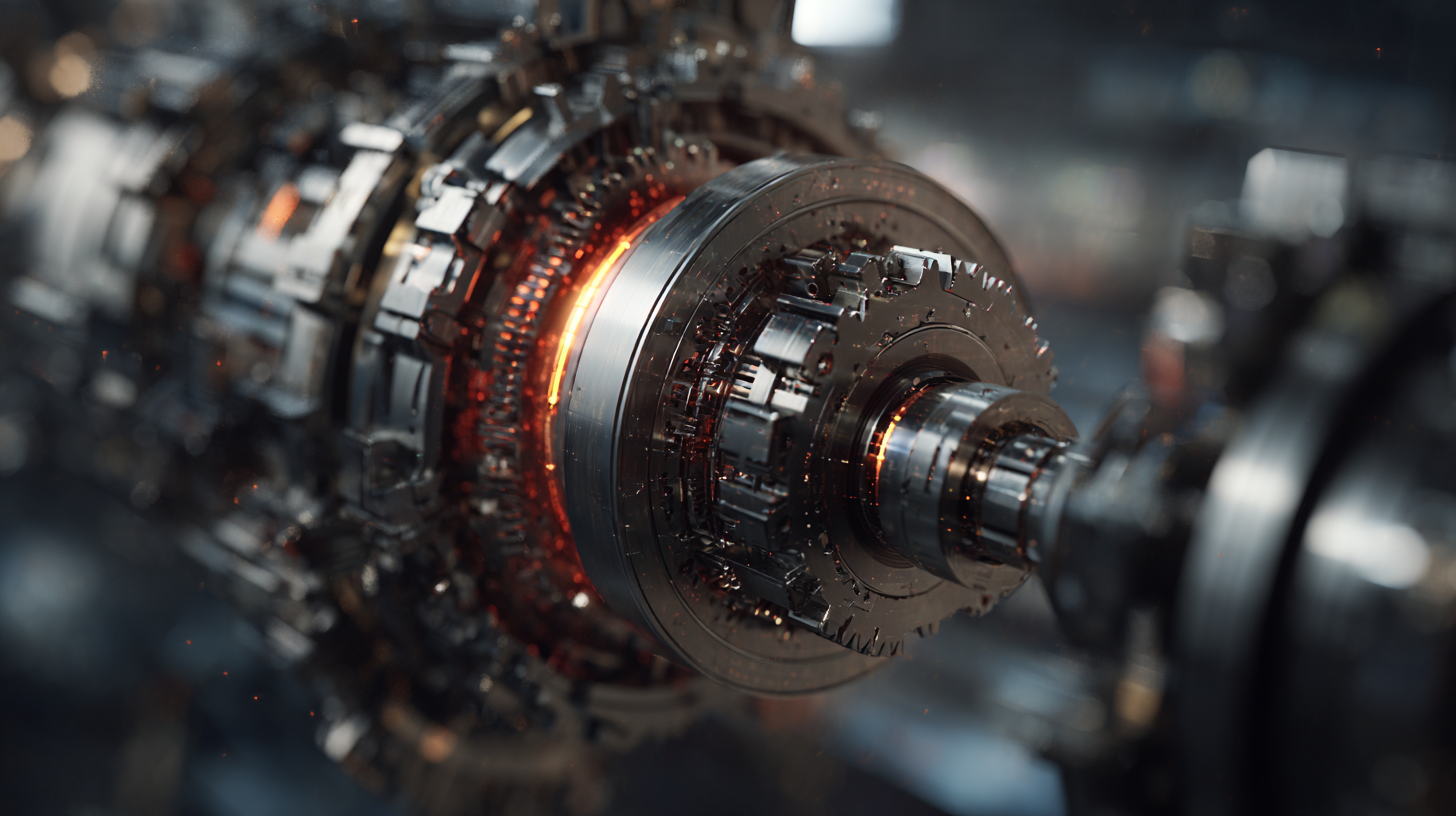

The integration of smart materials into steel fabrication is poised to revolutionize the construction industry. As the global metal fabrication equipment market anticipates growth from $64.64 billion in 2025 to $82.78 billion by 2032, with a compound annual growth rate (CAGR) of 3.6%, the demand for innovative solutions is increasing rapidly. Smart materials, characterized by their ability to respond dynamically to environmental stimuli, represent a key advancement in this sector. These materials not only enhance the structural performance of steel components but also optimize fabrication processes by integrating advanced technologies such as IoT and AI.

Incorporating smart materials enables real-time monitoring and management of construction projects, significantly improving efficiency and safety. For example, sensors embedded in steel structures can provide critical data about stress and temperature, allowing for proactive maintenance and reduced downtime. This level of integration is set to streamline workflow in fabrication, reduce waste, and ultimately lead to more sustainable construction practices. As the industry continues to explore these innovations, the potential for smarter, more resilient buildings becomes increasingly evident, making smart materials a cornerstone of future steel fabrication.

The global stainless steel market is projected to reach a value of $206.91 billion in 2023, with expectations to grow to $216.16 billion in 2024 and further to $320.37 billion by 2032. This robust growth reflects an increasing demand for innovative construction and fabrication techniques that align with modern sustainability goals. As the construction industry continues to evolve, there is a notable shift towards green building practices, driven by both environmental awareness and economic incentives. The trend towards sustainable steel construction is vital, as it not only reduces carbon footprints but also enhances the longevity and resilience of structures.

In addition to stainless steel, the market for pipes and tubes is also experiencing significant expansion. Spanning various applications, from oil and gas to automotive and construction, the demand for seamless and welded pipes is expected to rise sharply in the coming years. With urbanization and infrastructure development accelerating globally, the steel and rebar market is poised for substantial growth as well. Innovations in steel production and fabrication methods will be critical in meeting the projected increase in demand, particularly in response to the burgeoning trends in smart buildings and infrastructure, indicating a transformative future for the steel construction industry.