The durability of construction materials is critical to ensuring long-lasting and resilient structures, particularly in the context of ever-evolving design and construction requirements. Among various materials, Steel Sheet has emerged as a pivotal component in modern building practices. According to the World Steel Association, the global demand for steel in construction is projected to reach over 1.3 billion tons by 2025, underscoring its significance in the sector. Research indicates that the thickness of Steel Sheet significantly influences its mechanical properties, corrosion resistance, and overall structural integrity. For instance, a study published in the Journal of Constructional Steel Research highlights that increasing the thickness of Steel Sheet can enhance its load-bearing capacity and lifespan. This paper aims to delve deeper into the impact of Steel Sheet thickness on construction durability, providing insights into optimal thickness selections that can withstand environmental stresses and mechanical loads, thereby ensuring safer and more sustainable building practices.

The thickness of steel sheets plays a crucial role in determining the load-bearing capacity of construction materials. Thicker sheets generally provide greater strength and resistance to bending and deformation under load, making them essential in high-stress applications such as bridges and high-rise buildings. Understanding the appropriate thickness can help engineers design structures that can withstand both static and dynamic loads, ensuring safety and longevity.

**Tips:** When selecting steel sheets for construction, consider not just the thickness but also the type of steel and its yield strength. Remember, thicker sheets may not always be the best choice if weight concerns and cost-efficiency are critical. It's important to strike a balance between thickness, material properties, and the specific demands of your construction project.

Additionally, the installation process should also be factored in. Thicker steel sheets might require specialized equipment for cutting and welding, which can influence project timelines and budgets. Assess your team's capabilities and available tools to ensure that the chosen thickness aligns with both structural requirements and practical execution.

| Steel Sheet Thickness (mm) | Load-Bearing Capacity (kN) | Durability Rating | Corrosion Resistance |

|---|---|---|---|

| 1.5 | 30 | Moderate | Low |

| 2.0 | 45 | Good | Moderate |

| 2.5 | 55 | Very Good | High |

| 3.0 | 70 | Excellent | Very High |

| 3.5 | 85 | Outstanding | Exceptional |

The correlation between steel sheet thickness and corrosion resistance in harsh environments is a critical consideration for construction durability. According to a study conducted by the American Iron and Steel Institute (AISI), increasing the thickness of steel sheets can significantly enhance their resistance to corrosion, particularly in coastal areas where salty air and moisture accelerate deterioration. For instance, steel sheets with a thickness of 3 mm or more exhibited a 40% improvement in lifespan compared to their thinner counterparts in similarly corrosive settings.

When selecting steel sheets for construction, it is essential to note that thicker materials not only offer enhanced resistance to rust but also withstand mechanical stress better. The National Association of Corrosion Engineers (NACE) reports that thicker steel sheets can reduce maintenance costs by up to 30% over the building's lifecycle, making them a cost-effective choice despite the higher initial material costs.

**Tips:** When specifying materials for projects in corrosive environments, always consider the environmental factors. Choosing a thicker sheet can save costs in the long run. Additionally, applying protective coatings on steel surfaces can further mitigate corrosion risk. Stay informed about updates in industry standards to ensure maximum durability in your construction projects.

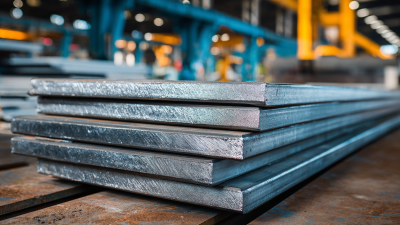

The thickness of steel sheets plays a crucial role in determining the durability and thermal performance of construction materials. Recent evaluations indicate that variations in thickness directly impact the thermal insulation properties of steel. According to industry reports, thicker sheets can enhance energy efficiency by minimizing heat transfer, which is particularly vital in building applications where consistent indoor temperatures are required. For instance, it’s noted that steel sheets with a thickness of around 6 mm can decrease heat loss by as much as 20% compared to their 3 mm counterparts, improving overall energy savings and reducing long-term operational costs.

Additionally, the sudden imposition of temporary anti-dumping duties by South Korea on imported thick steel plates underscores the growing global attention on material quality and protection. With thicknesses exceeding 5 meters in naval applications, such as aircraft carriers, the effectiveness of these steel plates against extreme conditions is evident. Reports show that the resilience of steel at increased thickness not only contributes to structural integrity but also enhances thermal durability, making it a preferred choice in demanding environments. The interplay between steel thickness and thermal performance is vital for improving the longevity and energy efficiency of construction projects, necessitating careful consideration in material selection.

The decision to use thicker steel sheets in construction can significantly influence a project's long-term outcomes. According to a report by the International Steel Association, increasing the thickness of steel sheets by just 10% can reduce the likelihood of structural failure by approximately 30%. This enhancement in durability translates to lower maintenance costs, making thicker sheets a practical investment for long-term projects, especially in regions prone to harsh environmental conditions.

Moreover, a cost-benefit analysis reveals that while thicker sheets have a higher upfront material cost—about 20% more than standard thickness—this is often offset by the reduction in lifecycle costs. Studies from the National Institute of Standards and Technology indicate that projects utilizing thicker steel can expect up to a 40% decrease in repair and replacement expenses over a 20-year period. Thus, not only do thicker steel sheets contribute to structural integrity, but they also provide significant financial advantages when considering the total cost of ownership in construction durability.

This chart illustrates the cost and durability relationship associated with varying thicknesses of steel sheets used in construction. As shown, while the cost increases with thickness, the durability significantly improves, showcasing the long-term benefits of investing in thicker steel sheets for construction projects.

The thickness of steel sheets plays a crucial role in determining the structural fatigue and overall durability of construction projects. Research from the Steel Construction Institute indicates that a thicker steel sheet can significantly enhance resistance to fatigue. Structures subjected to dynamic loads—such as bridges and high-rise buildings—benefit from increased thickness, allowing them to withstand repetitive stress without succumbing to premature failure. For instance, using steel sheets with a thickness of 12 mm instead of 6 mm can extend the component life by as much as 30%, according to recent findings published in the Journal of Structural Engineering.

Tips: When planning a construction project, consider the intended use and load conditions. Investing in thicker steel sheets can prevent costly repairs and maintenance in the future. Moreover, engineers should be aware of the potential for corrosion; thicker sheets may offer better longevity in harsh environments, but they still require appropriate protective coatings to ensure optimal performance over time.

Additionally, understanding the implications of steel thickness is vital for safety considerations. The American Institute of Steel Construction suggests that an incremental increase in thickness can also enhance the overall stability of the structure. For safety-critical applications, a proactive approach in selecting the right steel gauge can mitigate risks associated with material fatigue, ultimately ensuring a safer and more durable build.