Metal coil plays a pivotal role in a wide array of industrial applications and manufacturing processes, acting as a versatile foundation for numerous products and solutions. The significance of metal coils lies in their adaptability and ease of use across different sectors, including automotive, construction, and electronics. These materials are crafted from various metals such as steel, aluminum, and copper, each providing unique properties that cater to specific industrial needs. By understanding the essential functions and benefits of metal coils, industries can optimize their operations, improve efficiency, and enhance product quality.

Moreover, the manufacturing processes involving metal coil are often characterized by their precision and efficiency. Techniques such as rolling, cutting, and welding allow for the creation of components that meet stringent industry standards. As technology advances, innovations in metal coil production have further enhanced their performance, making them indispensable in modern manufacturing. Whether in the form of sheets, strips, or custom profiles, metal coils serve as a fundamental element that supports the infrastructure of various industrial sectors, highlighting their importance in the continuous drive for improved performance and sustainability.

Metal coils have become a cornerstone of industrial manufacturing processes, playing a critical role in various applications. According to a report by the International Energy Agency (IEA), the demand for metal products, particularly coils made from steel and aluminum, is projected to grow significantly, with an expected increase of over 4% annually in the industrial sector through 2030. This rise is driven by the increasing need for durable and high-quality materials in construction, automotive, and aerospace industries.

In manufacturing, metal coils are essential for processes such as stamping, rolling, and forming, which are integral for producing components used in machinery and infrastructure. A market research report by Research and Markets highlights that the global metal coil coating market alone is anticipated to reach nearly $27 billion by 2025, underlining the significance of metal coils in enhancing product durability and aesthetic quality. The ability to customize the thickness and coating of metal coils enables manufacturers to cater to specific needs, which is crucial in a competitive landscape where efficiency and adaptability are paramount.

Furthermore, the shift towards sustainability within industrial manufacturing has seen an increased focus on recycling and the use of lightweight materials, with metal coils often being a preferred choice. According to the Aluminum Association, nearly 70% of aluminum products are made from recycled materials, emphasizing the role of metal coils in promoting sustainable manufacturing practices. As industries move towards greener processes, the importance of metal coils will only continue to escalate, thereby redefining operational processes across various sectors.

| Dimension | Type of Metal Coil | Application | Industry |

|---|---|---|---|

| 0.5mm | Stainless Steel | Automotive Parts | Automotive |

| 1.0mm | Aluminum | HVAC Components | Construction |

| 1.5mm | Mild Steel | Structural Components | Manufacturing |

| 2.0mm | Galvanized Steel | Roofing Materials | Construction |

| 3.0mm | Copper | Electrical Wiring | Electronics |

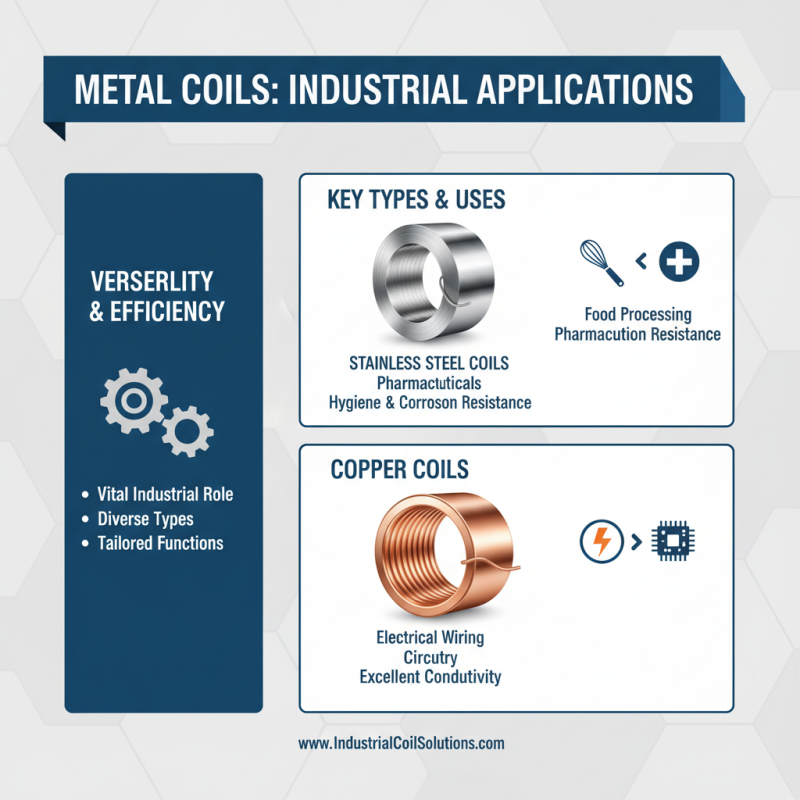

Metal coils play a vital role in various industrial applications due to their versatility and efficiency. There are several types of metal coils, each designed for specific functions across different sectors. For instance, stainless steel coils are commonly used in the food processing and pharmaceutical industries, where hygiene and resistance to corrosion are paramount. Similarly, copper coils are prominent in electrical applications, providing excellent conductivity for wiring and circuitry.

In addition, galvanized steel coils are widely utilized in construction for roofing and siding, offering durability and weather resistance. Aluminum coils also find their place in the automotive industry, where lightweight materials contribute to fuel efficiency without sacrificing strength. Each type of metal coil serves a distinct purpose, showcasing the importance of selecting the right material for the task at hand.

Tips: When choosing a metal coil for your project, consider factors such as the environment it will be used in, weight requirements, and thermal conductivity. Always consult with industry professionals to ensure you're selecting the appropriate type based on specific application needs. Understanding these materials will not only optimize performance but also enhance the longevity of your product.

The demand for metal coils in global manufacturing sectors has seen a significant rise in recent years, driven by various industrial applications ranging from automotive to construction. As industries increasingly focus on efficiency and sustainability, metal coils have emerged as a vital component for producing lightweight and durable products. Their ability to be easily shaped, cut, and processed makes them an ideal choice for manufacturers seeking flexibility in their production lines. This adaptability not only leads to cost savings but also helps in meeting the rising standards of quality and performance in various applications.

Market trends indicate that the demand for specific types of metal coils, such as aluminum and steel, is on the upswing. This growth is fueled by advancements in technology and an increasing emphasis on recycling and eco-friendly practices within the manufacturing process. As industries strive to reduce their carbon footprint and enhance resource efficiency, the versatility of metal coils positions them as a key material that aligns with these goals. Moreover, the global shift towards renewable energy sources is further propelling the need for metal coils, especially in the production of solar panels and wind turbines, making them integral to the transition towards sustainable manufacturing practices.

Metal coils play a pivotal role in various industrial applications due to their superior performance metrics, including strength, durability, and flexibility. Strength is crucial in sectors that require materials capable of withstanding high stress and operational loads. Metal coils are engineered to provide high tensile strength, making them ideal for construction, automotive, and machinery manufacturing where safety and reliability are paramount.

Durability is another vital aspect of metal coils. These materials resist wear and tear, enabling them to perform effectively over long periods, even in harsh environments. Industries often rely on metal coils to maintain structural integrity and reduce the frequency of replacements. This longevity contributes not only to cost savings but also to enhanced efficiency in manufacturing processes.

**Tips:** When selecting metal coils for your projects, always consider the specific requirements of your application. Assess the operating environment and choose coils with appropriate protective coatings to enhance their resistance to corrosion. Additionally, check the flexibility of the metal coils; some applications may require a balance between rigidity and pliability to fit complex designs or accommodate stress without fracturing.

The manufacturing sector has increasingly recognized the importance of sustainability, particularly in the production of metal coils. This essential component is used across various industrial applications, yet its production can significantly impact the environment if not managed properly. Sustainable practices in metal coil manufacturing focus on reducing waste, optimizing resource use, and minimizing carbon emissions. By implementing energy-efficient processes and utilizing recycled materials, manufacturers can contribute to a more sustainable industrial ecosystem.

Moreover, the shift towards sustainable metal coil production is not only beneficial for the environment but also aligns with the growing demand from consumers and industries for eco-friendly products. Companies are now exploring innovative technologies that enhance recycling capabilities and reduce energy consumption. For instance, adopting advanced manufacturing techniques, such as lean manufacturing and closed-loop systems, can lead to more efficient operations and lower environmental footprints. This transformation highlights the industry's commitment to sustainability while ensuring the continued availability and functionality of metal coils for diverse applications.