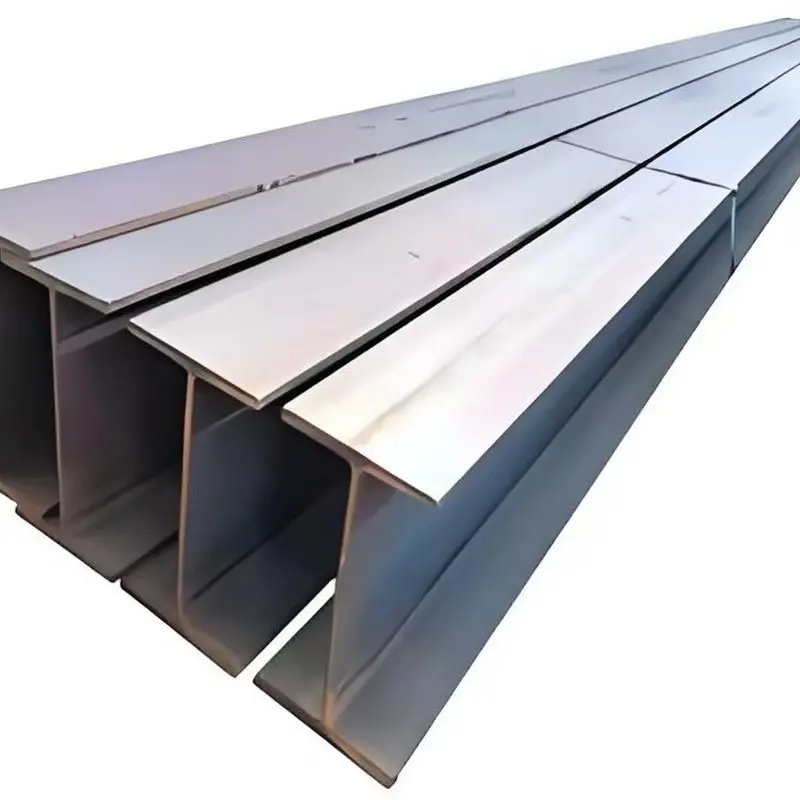

High Quality Standard Universal H Beam Sizes Steel H Beams

Product Description

I-beam, also known as steel beam, is a long steel with a cross-section of I-shape, I-beam is divided into ordinary I-beam, light I-beam and wide-wing I-beam, is a section steel with an I-shaped cross-section, according to the ratio of flange and web height, it is divided into wide, medium, narrow and wide flange I-beam. The specifications of the first two production are 10-60, that is, the corresponding height is 10 cm-60 cm, ordinary I-beam, light I-beam flange is variable cross-section by the web part thick, the outside is thin, ordinary I-beam, light I-beam has formed a national standard, H-shaped I-beam is also called wide flange I-beam, of which HW, HN I-beam has been widely used and produced in China.

(1) Diagonal rolling hole type system. This hole pattern system means that the two open legs of the I-beam hole type are not on the same side of the waist at the same time, and the waist has an angle with the horizontal axis.

(2) Straight rolled hole type system. The straight rolling hole pattern system refers to the hole pattern system in which the two open legs of the I-beam hole pattern are on the same side of the roll axis at the same time, and the waist is parallel to the roll axis.

(3) Mixed hole system. Depending on the characteristics of the rolling mill and the product, in order to give full play to the advantages of the respective systems, a mixed hole type system, that is, a combination of more than two systems, is often used. For example, the finished hole and the finished front hole adopt the straight leg oblique rolling hole type system, and the other hole types use the bent leg oblique rolling system; Or the coarse rolling hole adopts the direct rolling system, and the last 3~4 finishing rolling holes use the straight leg oblique piercing hole, etc.

(4) Special rolling method. If it is difficult to roll out the required I-beam by common rolling methods for some reason, a special rolling method can be used to make full use of the skills of uneven deformation and hole design. For example, when the billet section is narrow and a wide I-beam is required, the wave rolling method can be used; For example, when the billet is wider and requires rolling smaller I-beams, negative widening rolling can be used.

Product Parameters

| GB H beam | JIS H beam | ||||||

| SIZE(mm) | KG/m | SIZE(mm) | KG/m | SIZE(mm) | KG/m | SIZE(mm) | KG/m |

| 100*100*6*8 | 17.2 | 390*300*10*16 | 107 | 100*100*6*8 | 16.9 | 388*402*15*15 | 140 |

| 125'125*6.5*9 | 23.8 | 396*199*7*11 | 56.7 | 125*125*6.5*9 | 23.6 | 390*300*10*16 | 105 |

| 150*75*5*7 | 14.3 | 400*150*8*13 | 55.8 | 150*75*5*7 | 14 | 396*199*7*11 | 56.1 |

| 148*100*6*9 | 21.4 | 400*200*8*13 | 66 | 148*100*6*9 | 20.7 | 400*200*8*13 | 65.4 |

| 150*150*7*10 | 31.9 | 400*400*13*21 | 172 | 150*150*7*10 | 31.1 | 400*150*8*13 | 55.2 |

| 175*90*5*8 | 18.2 | 400*408*21*21 | 197 | 175*90*5*8 | 18 | 400*400*13*21 | 172 |

| 175*175*7.5*11 | 40.4 | 414*405*18*28 | 233 | 175*175*7.5*11 | 40.4 | 400*408*21*21 | 197 |

| 194*150*6*9 | 31.2 | 428*407*20*35 | 284 | 194*150*6*9 | 29.9 | 414*405*18*28 | 232 |

| 198*99*4.5*7 | 18.5 | 440*300*11*18 | 124 | 198*99*4.5*7 | 17.8 | 428*407*20*35 | 283 |

| 200*100*5.5*8 | 21.7 | 446*199*8*12 | 65.5 | 200*100*5.5*8 | 20.9 | 440*300*11*18 | 121 |

| 200*200*8*12 | 50.5 | 450*200*9*14 | 76.5 | 200*200*8*12 | 49.9 | 446*199*8*12 | 65.1 |

| 200*204*12*12 | 56.7 | 482*300*11*15 | 115 | 200*204*12*12 | 56.2 | 450*200*9*14 | 74.9 |

| 244*175*7*11 | 44.1 | 488*300*11*18 | 129 | 244*175*7*11 | 43.6 | 482*300*11*15 | 111 |

| 248*124*5*8 | 25.8 | 496*199*9*14 | 79.5 | 248*124*5*8 | 25.1 | 488*300*11*18 | 125 |

| 250*125*6*9 | 29.7 | 500*200*10*16 | 89.6 | 250*125*6*9 | 29 | 496*199*9*14 | 77.9 |

| 250*250*9*14 | 72.4 | 506*201*11*19 | 103 | 250*250*9*14 | 71.8 | 500*200*10*16 | 88.2 |

| 250*255*14*14 | 82.2 | 582*300*12*17 | 137 | 250*255*14*14 | 81.6 | 506*201*11*19 | 102 |

| 294*200*8*12 | 57.3 | 588*300*12*20 | 151 | 294*200*8*12 | 55.8 | 582*300*12*17 | 133 |

| 294*302*12*12 | 85 | 594*302*14*23 | 175 | 294*302*12*12 | 83.4 | 588*300*12*20 | 147 |

| 298*149*5.5*8 | 32.6 | 596*199*10*15 | 95.1 | 298*149*5.5*8 | 32 | 594*302*14*23 | 170 |

| 298*201*9*14 | 65.4 | 600*200*11*17 | 106 | 300*150*6.5*9 | 36.7 | 596*199*10*15 | 92.5 |

| 300*150*6.5*9 | 37.3 | 606*201*12*20 | 120 | 300*300*10*15 | 93 | 600*200*11*17 | 103 |

| 300*300*10*15 | 94.5 | 692*300*13*20 | 166 | 300*305*15*15 | 105 | 606*201*12*20 | 118 |

| 300*305*15*15 | 106 | 700“300*13-24 | 185 | 340*250*9*14 | 78.1 | 692*300*13*20 | 163 |

| 340*250*9*14 | 79.7 | 792*300*14*22 | 191 | 346*174*6*9 | 41.2 | 700*300*13*24 | 182 |

| 346*174*6*9 | 41.8 | 800*300*14*26 | 210 | 350*175*7*11 | 49.4 | 800*300*14*26 | 207 |

| 350*175*7*11 | 50 | 900*300*16*28 | 243 | 350*350*12*19 | 135 | ||

| 350*350*12*19 | 137 | ||||||

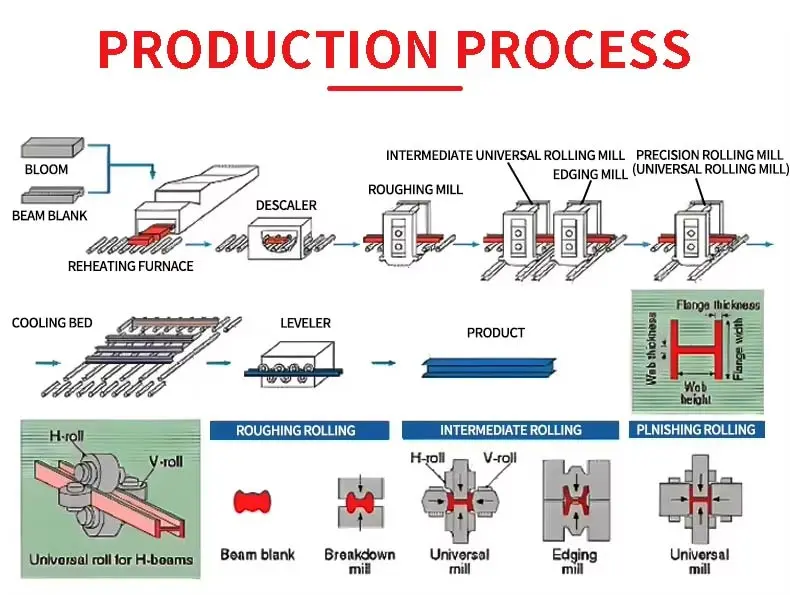

Production Flow Chart

Project Case

Pack And Ship

Certificate

Customer Praise

Plant And Equipment

FAQ

Q: How could I get a sample?

A: Before we received the first order, please afford the sample cost and express fee. We will return the sample cost back to you within your first order.

Q: Whether you could make our brand on your products?

A: Yes. We can print your Logo on both the products and the packages if you can meet our MOQ.

Q: How to guarantee the quality of your products?

A: 1.Strict detection during production.

A: 2.Strict sampling inspection on products before shipment and intact product packaging ensured.

Q: Which payment terms can you accept?

A: We can accept the TT, Western Union now or Negotiation