Factory Supply High Tensile Galvanized Steel Wire

| Material | Q195/Sae1006/Sae1008/Sea1020 |

| Tolerance | ±5% |

| Standard | ASTM/GB |

| Processing services | Cutting/Bending |

| Shipping date | 15-21days |

| Price terms | FOB/CFR/CIF/EXW/ETC |

| Application | Construction |

| Package | Standard Sea-worthy Packing |

The main processes of steel wire production include raw material selection, removal of iron oxide scale, drying, coating treatment, heat treatment, wire drawing, plating treatment, etc.

For the selection of raw materials, see steel wire raw materials.

Removal of iron oxide scale refers to the removal of iron oxide scale on the surface of wire rod or intermediate wire blank, in order to prevent iron oxide scale from damaging the surface of the mold and steel wire during drawing, to prepare good surface conditions for subsequent coating or plating treatment, and to reduce friction and tension during drawing. There are two types of methods for removing iron oxide scale: chemical method and mechanical method, see wire rod chemical descaling and wire rod mechanical descaling

Product Parameters

| Galvanized steel wire | |||||

| Diameter (mm) | Tolerance (mm) | Tensile Strength No Less Than (MPA) | Torsion Test No less Than (times) | Bend Times No Less Than (times) | Zinc Coating Mass No Less Than (g/m2) |

| 0.45 | +/-0.01 | 1770 | 28 | 5 | 5 |

| 0.50 | +/-0.01 | 1770 | 28 | 5 | 5 |

| 0.60 | +/-0.01 | 1770 | 28 | 9 | 5 |

| 0.70 | +/-0.01 | 1670 | 28 | 7 | 10 |

| 0.80 | +/-0.01 | 1670 | 28 | 13 | 10 |

| 0.90 | +/-0.02 | 1570 | 28 | 11 | 15 |

| 1.00 | +/-0.02 | 1470 | 27 | 9 | 20 |

| 1.20 | +/-0.02 | 1470 | 27 | 15 | 20 |

| 1.30 | +/-0.02 | 1370 | 27 | 13 | 20 |

| 1.40 | +/-0.02 | 1370 | 27 | 11 | 20 |

| 1.60 | +/-0.03 | 1370 | 27 | 13 | 20 |

| 1.80 | +/-0.03 | 1370 | 27 | 11 | 30 |

| 2.00 | +/-0.03 | 1270 | 25 | 10 | 30 |

| 2.40 | +/-0.03 | 1270 | 25 | 11 | 30 |

| 2.60 | +/-0.03 | 1270 | 25 | 10 | 35 |

| 2.77 | +/-0.03 | 1270 | 25 | 9 | 35 |

Production Flow Chart

Project Case

Pack And Ship

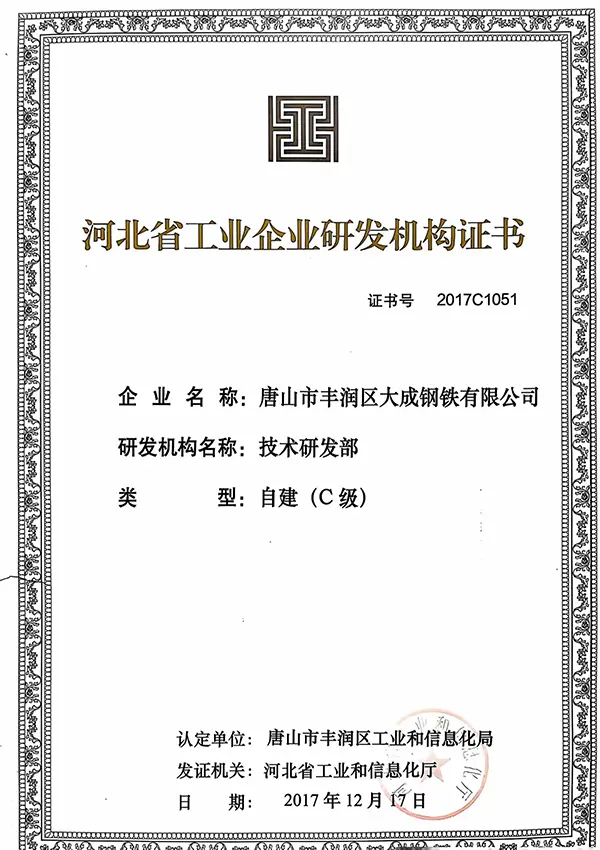

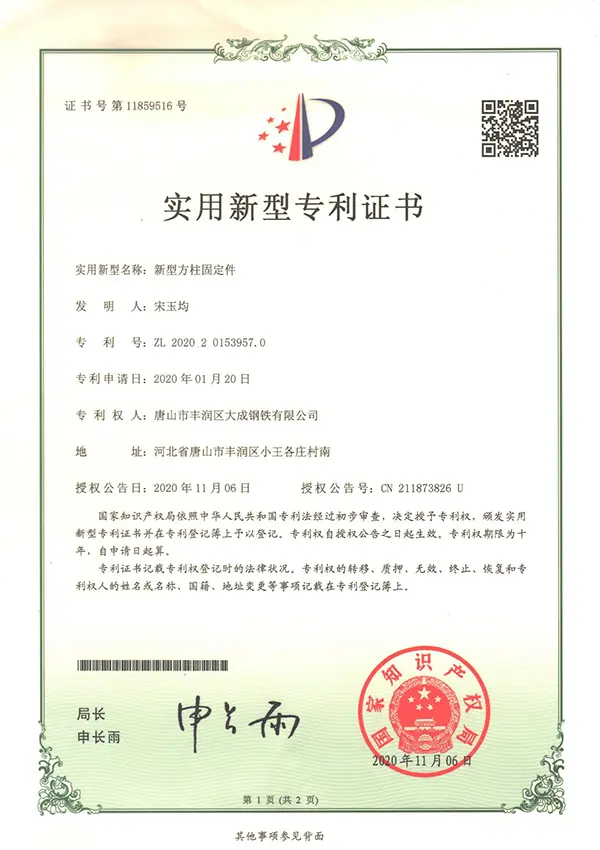

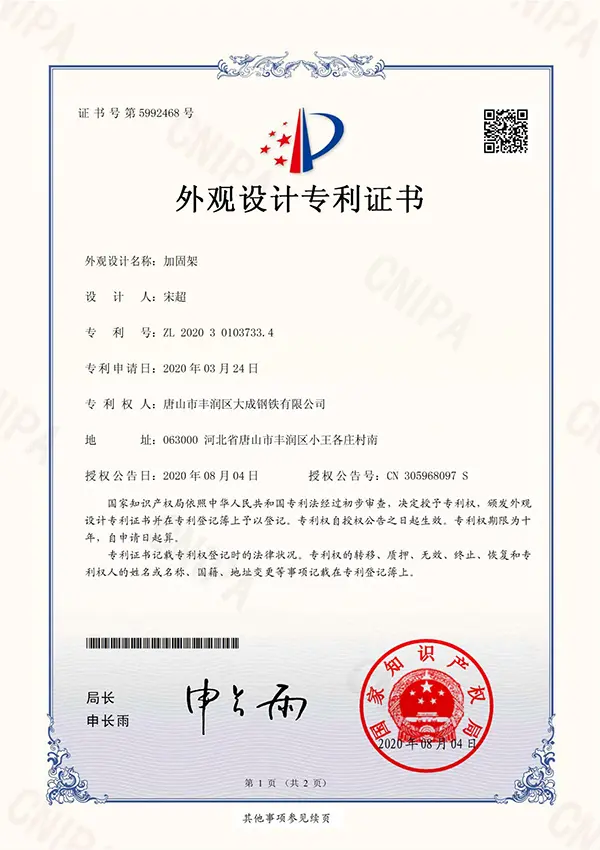

Certificate

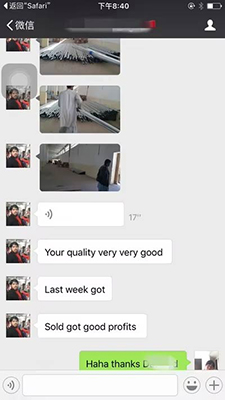

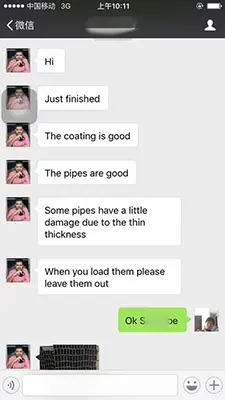

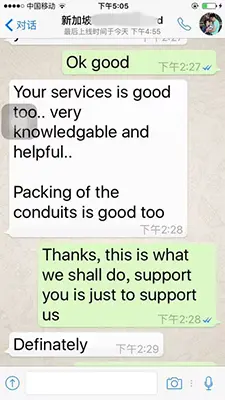

Customer Praise

Plant And Equipment