Customized Steel Rebar Truss Floor For Construction

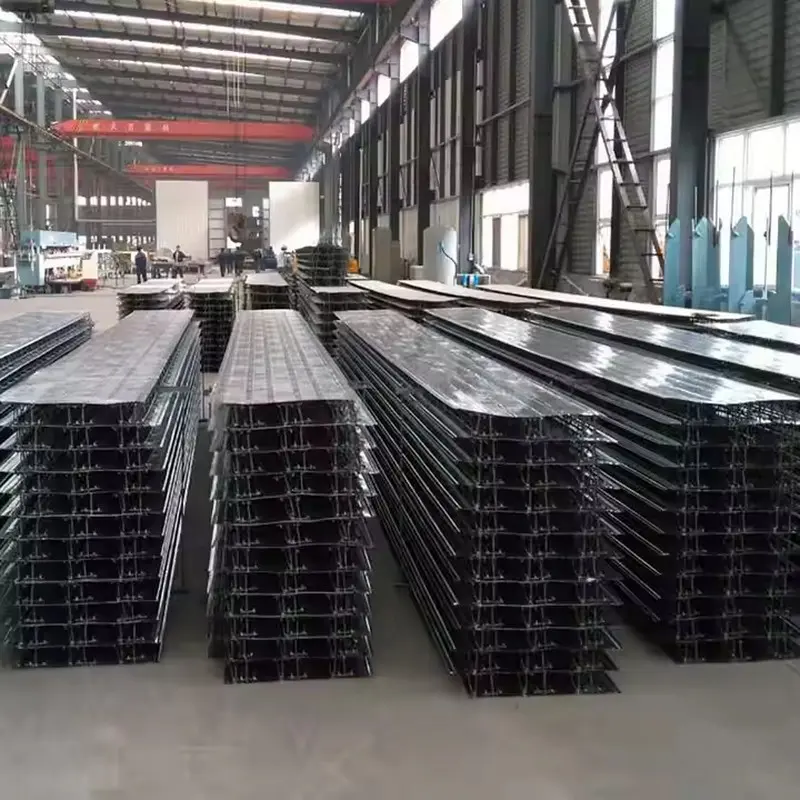

The mechanized production of steel truss floor deck is realized, which is conducive to the uniform arrangement and spacing of steel bars, the consistency of the thickness of the concrete protective layer, and the construction quality of the floor slab is improved. The prefabricated steel bar truss floor bearing plate can significantly reduce the amount of on-site steel bar binding work, speed up the construction progress, increase the construction safety guarantee, and realize civilized construction.

The prefabricated formwork and connectors are easy to disassemble and assemble, can be reused many times, save steel, and meet the requirements of national energy conservation and environmental protection. The products independently developed by the steel structure are equipped with automatic production equipment, which greatly improves labor productivity and effectively reduces product costs

The prefabricated formwork and connectors are easy to disassemble and assemble, can be reused many times, save steel, and meet the requirements of national energy conservation and environmental protection. The products independently developed by the steel structure are equipped with automatic production equipment, which greatly improves labor productivity and effectively reduces product costs

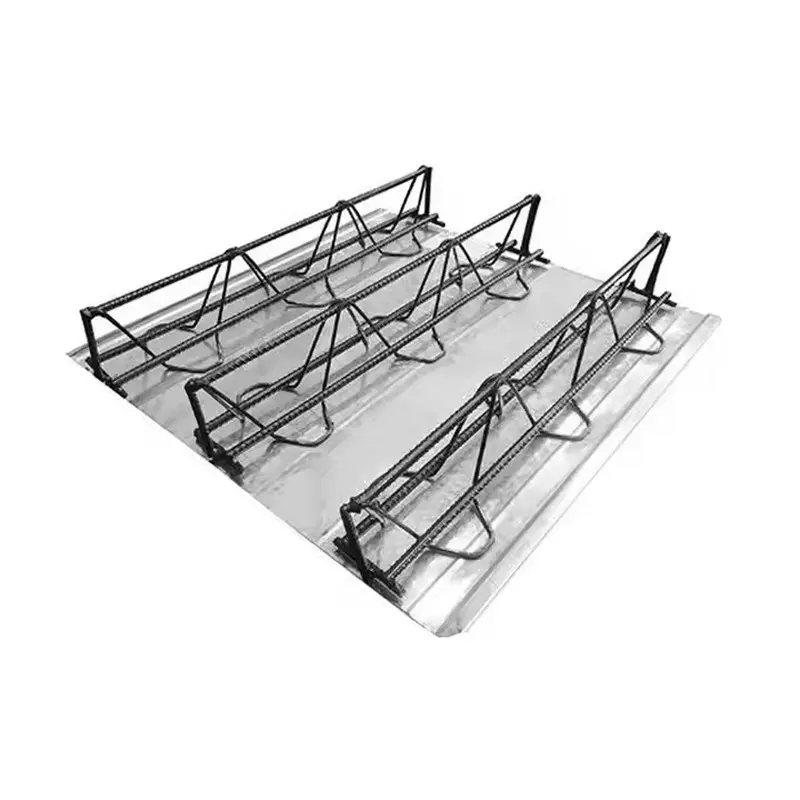

The truss floor deck plate, also known as the steel bar truss formwork, is a composite structural system formed by using special equipment to process the main stressed steel bars in the floor slab into a steel truss in the factory, and then weld the steel bar truss and galvanized steel plate into a whole.

In the construction stage of the structural floor slab, the system replaces the construction template with galvanized steel plates, and bears the concrete weight and construction load of the floor slab together with the truss structure formed by steel bar welding in the structure. After the concrete is poured, a reinforced truss concrete floor slab is formed, which bears the service load during the use phase.

In the construction stage of the structural floor slab, the system replaces the construction template with galvanized steel plates, and bears the concrete weight and construction load of the floor slab together with the truss structure formed by steel bar welding in the structure. After the concrete is poured, a reinforced truss concrete floor slab is formed, which bears the service load during the use phase.

Product Parameters

| Zinc coating | 30-275g |

| Steel sheet material | Q235 Q245 |

| Top and bottom bar diameter | 6-12mm |

| Distributing bar diameter | 6-12mm |

| The height of the truss | 70-270mm |