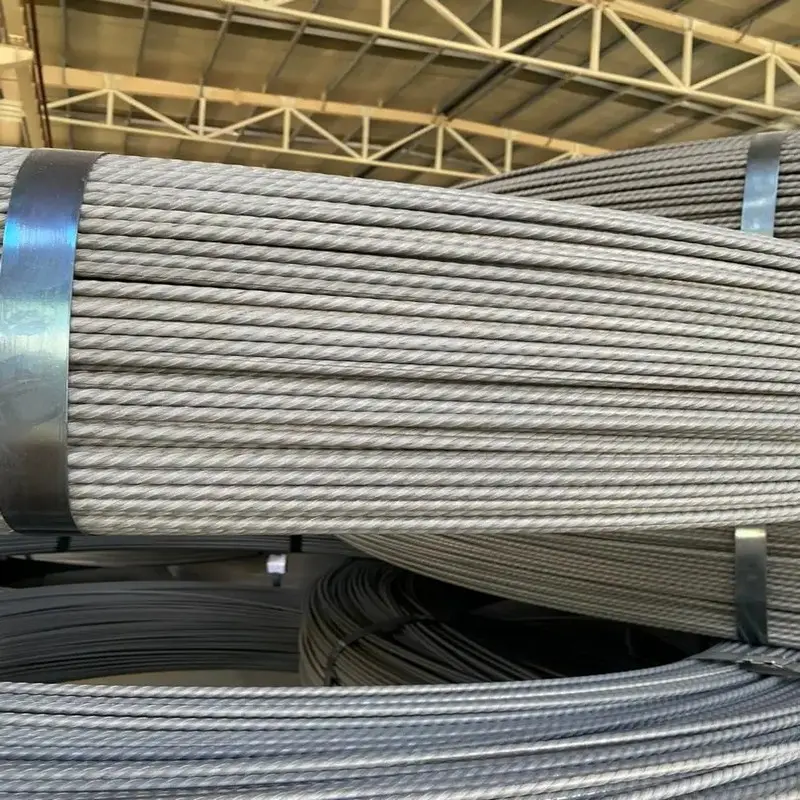

High Tensile PC Wire Prestressed Concrete Steel Wire

Cold-drawn steel wire for making reinforcement bars in tension areas of prestressed concrete members. Generally, concrete has high strength to compressive force, but it shows brittleness when it is subjected to tensile force, and it is easy to crack. Prestressed concrete is to make the steel bar in the tension area of the member bear a tensile force in advance and produce a pre-tensile stress. The pretension stress on the steel bar can offset or reduce the tensile stress of the external load on the concrete, thus greatly improving the ability of the tension area to resist the tension, thus reducing the size of the component, saving materials and reducing the weight of the component. Due to these advantages, prestressed concrete components have been successfully applied in many projects such as large Bridges, roof frames, crane beams, industrial and civil prefabricated floors, iron rail ties, electric pole piles, large diameter prefabricated pipelines and atomic power stations. The production of prestressed steel wire has been developed rapidly with the wide application of prestressed concrete members.

1.A general term for steel wires made of high-quality high-carbon steel hot-rolled wire rods by heat treatment and cold working suitable for prestressed concrete reinforcement requirements.

2.The carbon content of this type of steel wire steel is 0.65%~0.85%, and the sulfur and phosphorus content is less than 0.035%. The tensile strength of steel wire is generally above 1470MPa, and its strength level has gradually transitioned from 1470MPa and 1570MPa to 1670~1860MPa.

3.It is used in houses, highway and railway bridges, sleepers, electric poles, pressure water pipes, storage tanks, water towers, etc., and expands to modern high-rise buildings, underground buildings, high-rise structures, hydraulic buildings, marine structures, airport buildings (runways and terminals), nuclear power plant pressure vessels, etc.

| Material | Q195/q235/sae1006/sae1008 77b82b |

| Tolerance | ±5% |

| Specification | 4.8/5.0/6.0/6.25/7/8/9 |

| Processing services | Welding/Bending |

| Shipping date | 15-21days |

| Price terms | FOB/CFR/CIF/EXW/ETC |

| Application | Construction |

| Package | Standard Sea-worthy Packing |

Product Parameters

| Diameter (mm) | Tensile Strength (n/mm2) | ||

| SW-A | SW-B | SW-C | |

| 1.0 | 1471~1716 | 1716~1961 | 1961~2206 |

| 1.2 | 1422~1667 | 1667~1912 | 1912~2158 |

| 1.4 | 1373~1618 | 1618~1863 | 1863~2108 |

| 1.6 | 1324~1569 | 1569~1814 | 1814~2059 |

| 1.8 | 1275~1520 | 1520~1765 | 1765~2010 |

| 2.0 | 1275~1471 | 1471~1716 | 1716~1961 |

| 2.3 | 1226~1422 | 1422~1667 | 1667~1912 |

| 3.0 | 1177~1373 | 1373~1618 | 1618~1863 |

| 3.5 | 1177~1373 | 1373~1618 | 1618~1863 |

| 4.5 | 1128~1324 | 1324~1520 | 1520~1716 |

| 5.0 | 1260~1450 | 1460~1650 | 1660~18 |

Factory

1. who are we?

We are based in China, start from 2016,sell to Mid East(40.00%),South America(15.00%),Southeast Asia(15.00%),South Asia(5.00%),Eastern Asia(5.00%),North America(5.00%),Africa(5.00%),Oceania(3.00%),Southern Europe(2.00%),Central America(2.00%),Western Europe(1.00%),Northern Europe(1.00%),Eastern Europe(1.00%). There are total about 1000+ people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

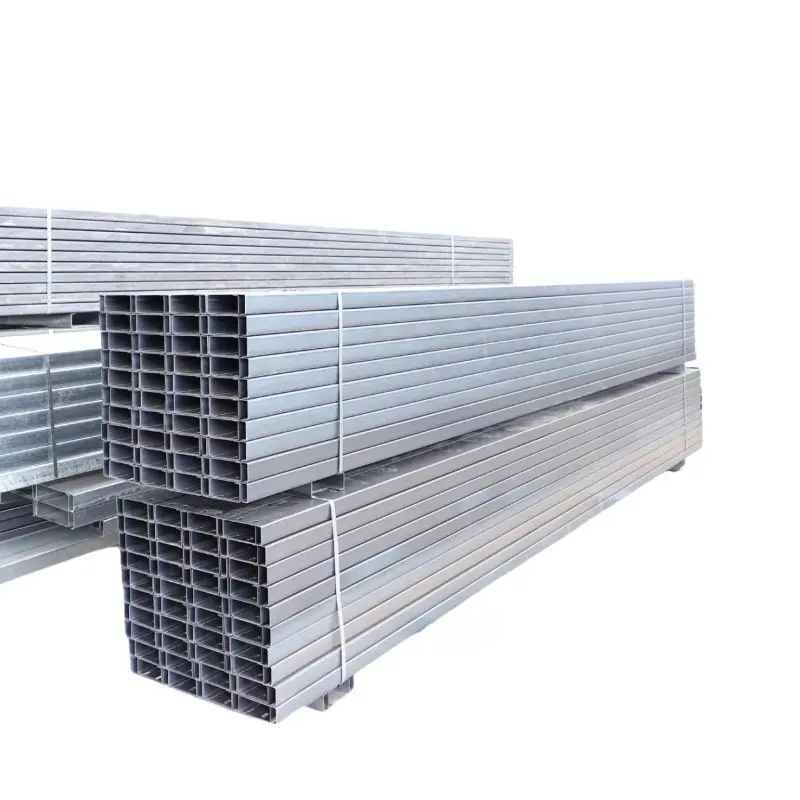

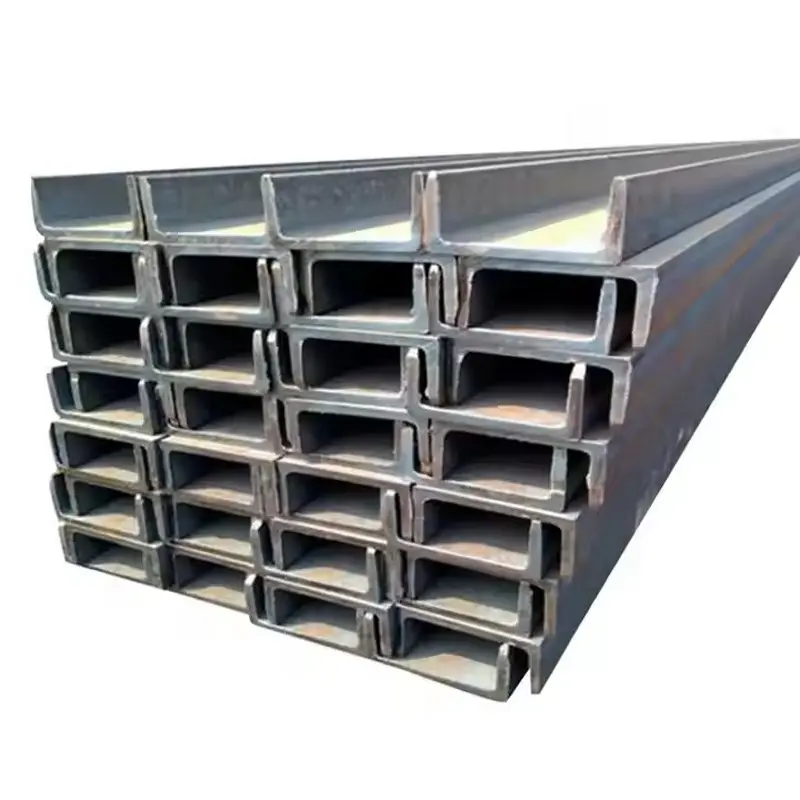

Black Square Steel Pipe/Black Rectangular Steel Pipe/LSAW Round Steel Pipe /Galvanized Square Rectangular Steel Pipe

4. why should you buy from us not from other suppliers?

THE LARGEST MANUFACTURER OF HOLLOW SECTION IN CHINA

Annual production capacity 5 million tons

Delivery time is fast

Yuantai has biggest hollow section stock

Yuantai get BV, CE, ISO, JIS ,PHD,EPD,BC1,certificates

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,PayPal,Cash;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian