Hot Rolled ASTM A690 Steel Sheet Piles SY295SY390 for Seawall

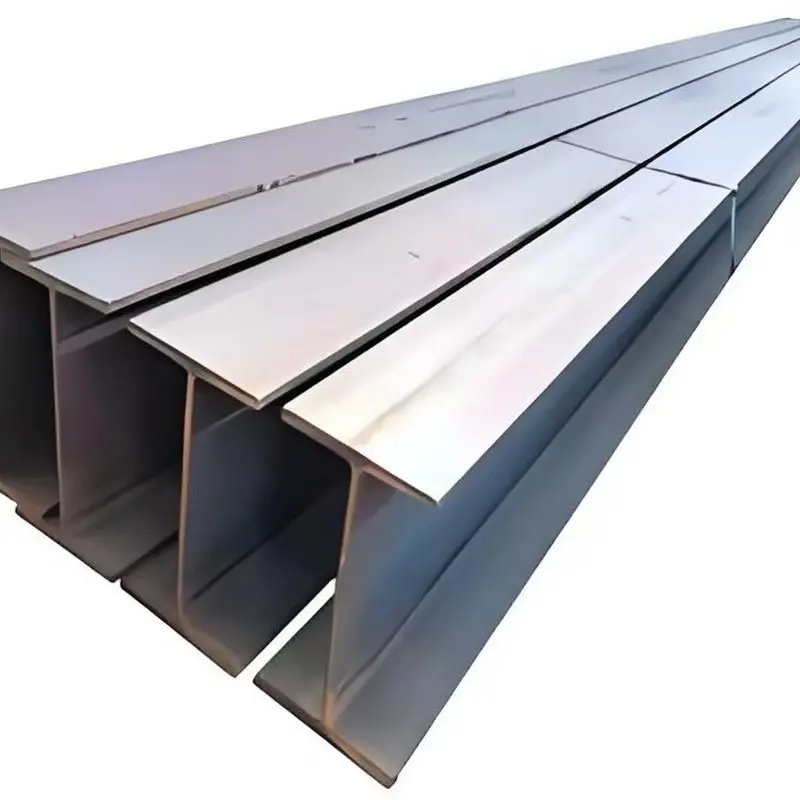

Hot-rolled steel sheet piles There are several major categories of hot-rolled steel sheet piles in the world, including U-type, Z-type, AS-type, H-type, and dozens of specifications. The production, processing, and installation processes of Z-type and AS-type steel sheet piles are relatively complex, and they are mainly used in Europe and the United States; domestically, U-type steel sheet piles are mainly used. Production process: formed by high-temperature rolling by a steel rolling mill. Advantages: standardized size, superior performance, reasonable cross-section, high quality, and tight water-proofing with locking bite. Disadvantages: greater technical difficulty, higher production cost, and inflexible specification series.

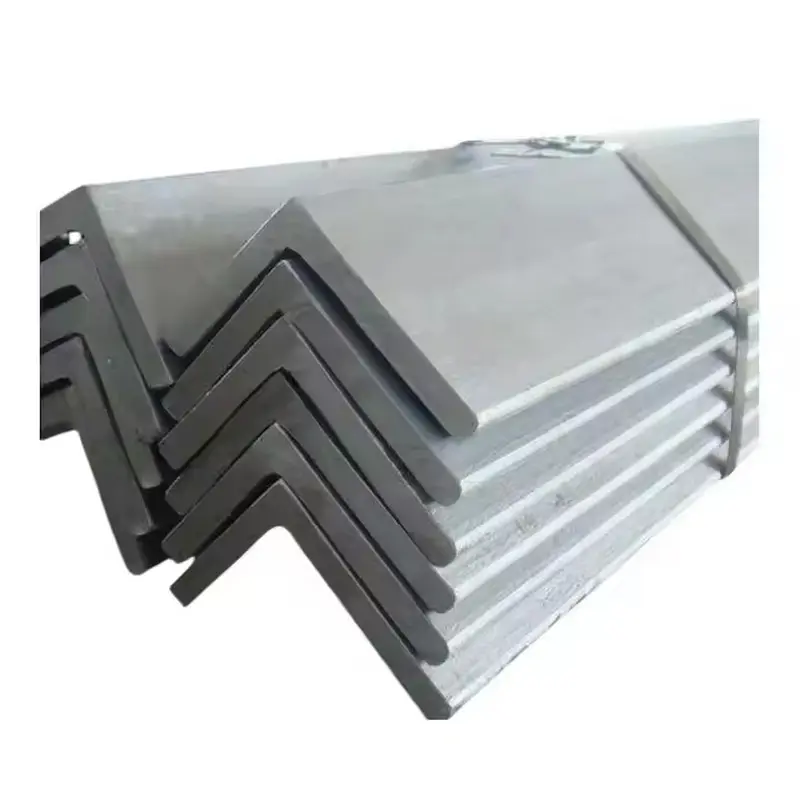

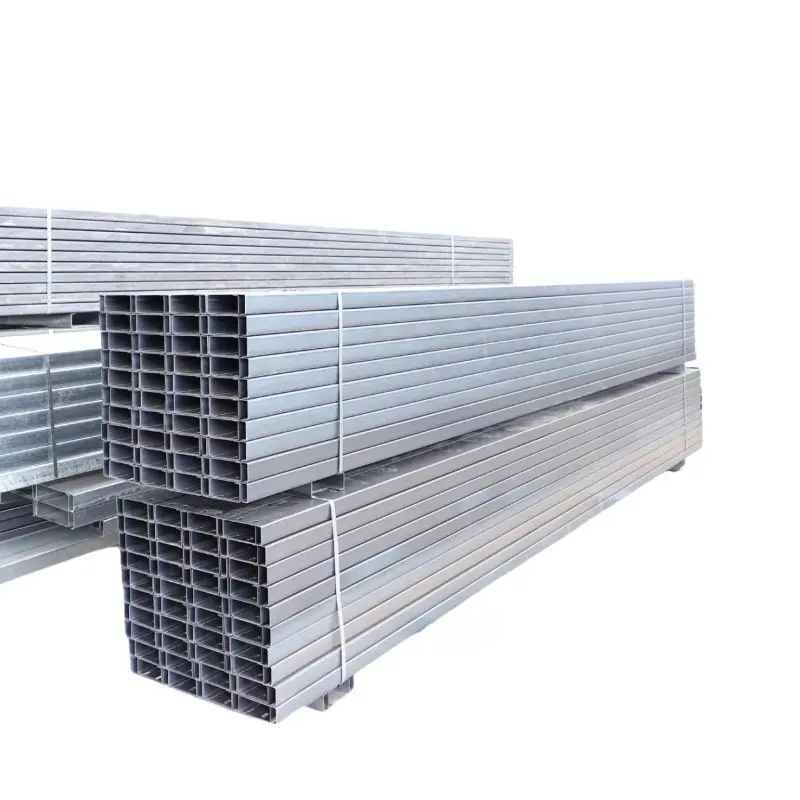

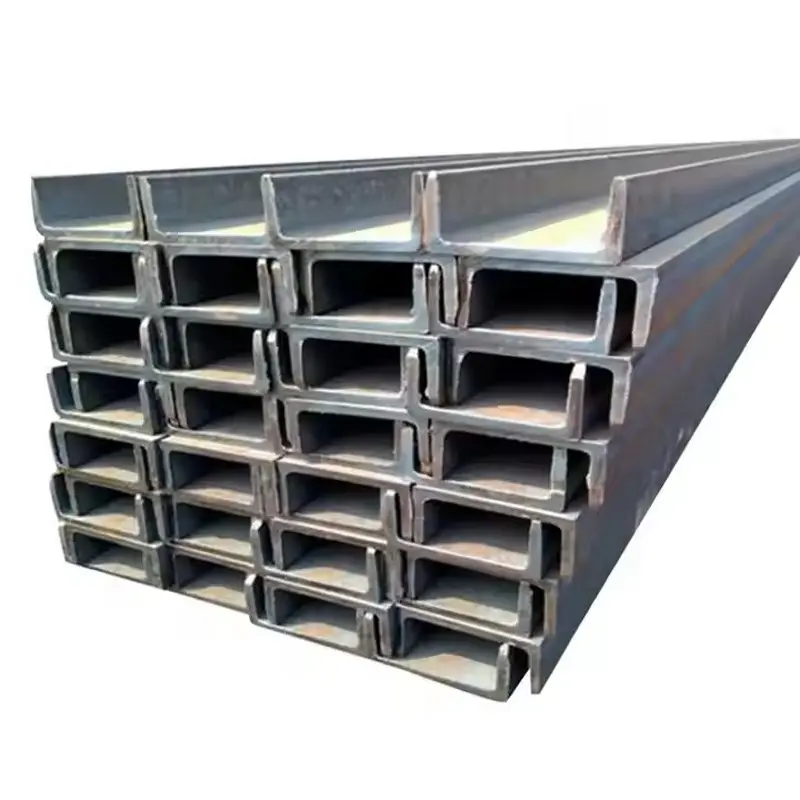

There are two types of cold-formed steel sheet piles: non-bite cold-formed steel sheet piles (also called channel plates) and bite-type cold-formed steel sheet piles (divided into L-type, S-type, U-type, and Z-type). Production process: Thinner plates (commonly used thickness 8mm to 14mm) are continuously rolled and formed in the cold-bending unit. Advantages: Low investment in the production line, low production cost, and flexible control of product length. Disadvantages: The thickness of each part of the pile body is the same, the cross-sectional size cannot be optimized, resulting in an increase in steel consumption, the shape of the locking part is difficult to control, the joints are not tightly buckled and cannot stop water, and the pile body is prone to tearing during use.

There are two types of cold-formed steel sheet piles: non-bite cold-formed steel sheet piles (also called channel plates) and bite-type cold-formed steel sheet piles (divided into L-type, S-type, U-type, and Z-type). Production process: Thinner plates (commonly used thickness 8mm to 14mm) are continuously rolled and formed in the cold-bending unit. Advantages: Low investment in the production line, low production cost, and flexible control of product length. Disadvantages: The thickness of each part of the pile body is the same, the cross-sectional size cannot be optimized, resulting in an increase in steel consumption, the shape of the locking part is difficult to control, the joints are not tightly buckled and cannot stop water, and the pile body is prone to tearing during use.

Product Parameters

|

Product name |

Steel sheet pile |

|

Grade |

S235、S330、S355、 S390、 S430、 SY295、 SY390、SYW295、SYW390、Q235、Q345 |

|

Standards |

AISI, ASTM, Bs, DIN, GB, JIS |

|

Dimensions |

customized |

|

Length: |

up to 80m |

|

Corner Sections |

Cold formed interlock or clutches |

|

Profiles |

U,Z,L,S,Pan,Flat,hat profiles |

|

Surface Treatment |

Black, painted or galvanized |

|

price terms |

FOB,CRF,CIF,EXW all acceptable |

|

Delivery Detail |

inventory About 3-5; custom-made 10-15;rding to order's quantity. |

|

Loading port |

any port in China |

|

Packing |

standard export packing (inside:water proof paper,outside:steel covered with strips and pallets) |

|

Payment Terms |

T/T, L/C at sight,West Union,D/P,D/A,Paypal |

FAQ

Q1: Are you trading company or manufacturer ?

A1: We are factory.

Q2: How long is your delivery time?

A2: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

Q3: Do you provide samples ? is it free or extra ?

A3: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q4:What is the advantage about your company?

A4:Our company has professional team and professional production line.

Q5: The logo and the color can be customized?

A5: Yes, we welcome you to sample custom

Q6: Any other good service your company can provide?

A6:Yes,we can provide good after-sale and fast delivery.