Manufacturers Ensure Quality at Low Prices Galvanized Steel Sheet Pipe

Product Description

Galvanized pipes are often mentioned. The use of galvanized pipes. The iron pipes used for gas and heating are also galvanized pipes. Galvanized pipes are used as water pipes. After a few years of use, a lot of rust will be generated in the pipes. The yellow water flowing out not only pollutes the sanitary ware, but also contains bacteria that grow on the rough inner wall. The rust causes excessive heavy metal content in the water, which seriously endangers human health.

Technical requirements

1. Brand and chemical composition

The brand and chemical composition of steel used for galvanized steel pipes shall comply with the brand and chemical composition of steel used for black pipes specified in GB/T3092.

2. Manufacturing method

The manufacturing method of black pipes (furnace welding or electric welding) is selected by the manufacturer. Galvanizing adopts hot-dip galvanizing method.

3. Threads and pipe joints

a: For galvanized steel pipes delivered with threads, the threads should be machined after galvanizing. The threads should comply with the provisions of YB 822.

b: Steel pipe joints shall comply with the provisions of YB 238; forgeable cast iron pipe joints shall comply with the provisions of YB 230.

4. Mechanical properties The mechanical properties of steel pipes before galvanizing shall comply with the provisions of GB 3092.

5. Uniformity of galvanized layer Galvanized steel pipes shall be tested for uniformity of galvanized layer. The steel pipe sample shall not turn red (copper color) after being immersed in copper sulfate solution for 5 consecutive times.

6. Cold bending test Galvanized steel pipes with a nominal diameter not exceeding 50mm shall be subjected to cold bending test. The bending angle is 90° and the bending radius is 8 times the outer diameter. No filler is carried out during the test, and the weld of the sample shall be placed on the outside or upper part of the bending direction. After the test, there shall be no cracks or peeling of zinc layer on the sample.

7. Water pressure test The water pressure test shall be carried out on black pipes, and eddy current flaw detection can also be used instead of water pressure test. The size of the test pressure or eddy current flaw detection comparison sample shall comply with the provisions of GB 3092. The mechanical properties of steel are important indicators to ensure the final performance (mechanical properties) of steel.

Product Parameters

| Material | Q195,Q235,Q345 |

| Tolerance | ±5% |

| Application | Construction |

| Processing services | Cutting/Welding/Bending |

| Shipping date | 15-21days |

| Price terms | FOB/CFR/CIF/EXW/ETC |

| Standard | ASTM,BS,GB |

| Package | Standard Sea-worthy Packing |

| Product name | Round pipe |

| Technical standard | Cold Rolled /Hot Rolled |

| Thickness | 0.6 - 30 mm or customized |

| Length | 6m,12m or customized |

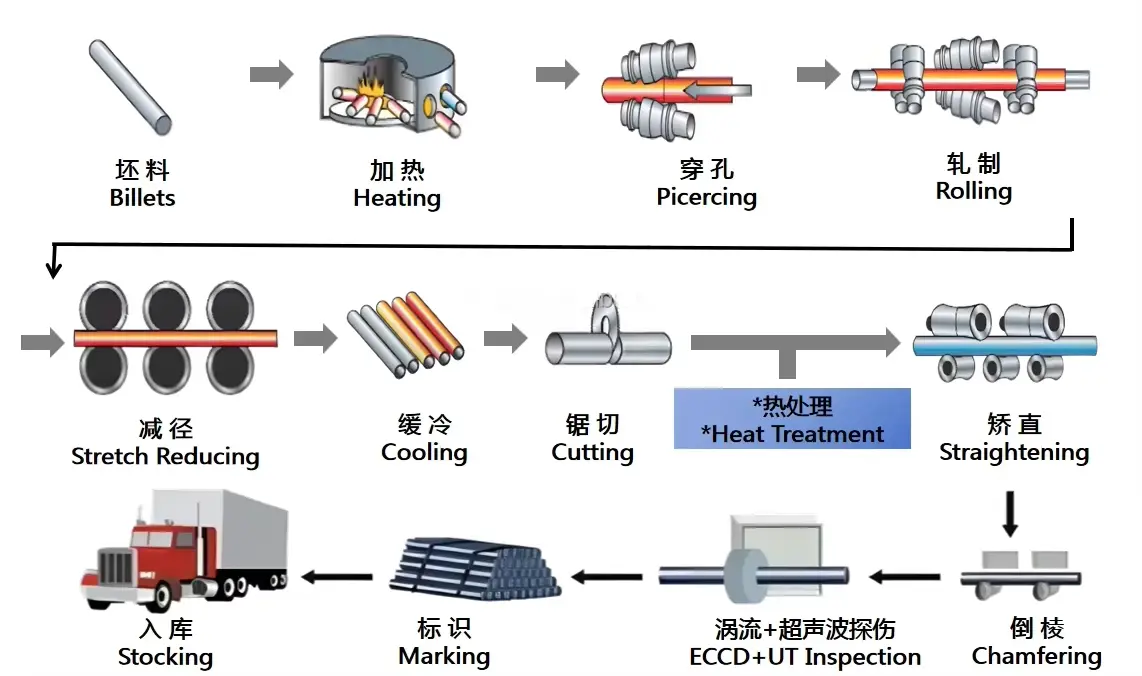

Production Flow Chart

Project Case

Pack And Ship

Certificate

Customer Praise

Plant And Equipment

FAQ

Q1: Are you manufacturer or trader?

A: Yes, we are manufacturer and trader, and if you need other special product, we will do our best to help you, so that we can build a long-term business relationship.

Q2: Can I order the product with special size?

A: Of course you can, and meanwhile according to your detail requests.

Q3: Why your best choice?

A: We have direct factory and many vears of export experience, and offer the best price with high quality product, timely delivery, also have good after-sales service, therefore with good reputation and many clients have good long-term business relationship.

Q4: Accepted terms of dellvery ?

A:We accept EXW.FOB.CFR.CIF.etc. you can choose the one which is the most convenient or cost effective for you

Q5: How to order ?

A:Please send us your purchase order by email or fax. Or you can ask us to send a proforma invoice for your order.We need to know the following inforation for your order.