High Quality High Tensile Strength Hot Rolled Galvanized Steel Wire Coils Rod In Coils For The Building Use

1080 Steel Wire 10mm 9mm Carbon Steel Wire Large Wire Din Steel Standard

Product Description

1.Galvanized steel wire is made by drawing high-quality carbon structural steel such as 45#, 65#, 70#, etc., and then galvanizing (electro-galvanized or hot-dip galvanized).

Galvanized steel wire is a carbon steel wire that is galvanized on the surface by hot-dipping or electroplating methods. Its properties are the same as those of straightened tempered steel wire. It can be used as an unbonded prestressed tendon, but it should be plated with at least 200~300g of zinc per square meter area. Parallel steel wire cables commonly used as cable-stayed bridges (in addition, flexible cable sleeves are also used as outer protection)

2.The surface of galvanized steel wire is smooth, smooth, without cracks, knots, punctures, scars and rust, and the galvanized layer is uniform, strong adhesion, long-lasting corrosion resistance, and excellent toughness and elasticity. The tensile strength should be between 900Mpa and 2200Mpa (wire diameter Φ0.2mm-Φ4.4mm). The number of twists (Φ0.5mm) should be more than 20 times, and the repeated bending times should be more than 13 times.

The thickness of the hot-dip zinc layer is 250g/m. The corrosion resistance of the steel wire is greatly improved.

3.Galvanized steel wire is mainly used in the manufacture of planting greenhouses, breeding farms, cotton bales, springs and wire ropes. It is suitable for engineering structures with harsh environmental conditions such as steel cables and sewage pools of cable-stayed bridges

Galvanized steel wire is a carbon steel wire that is galvanized on the surface by hot-dipping or electroplating methods. Its properties are the same as those of straightened tempered steel wire. It can be used as an unbonded prestressed tendon, but it should be plated with at least 200~300g of zinc per square meter area. Parallel steel wire cables commonly used as cable-stayed bridges (in addition, flexible cable sleeves are also used as outer protection)

2.The surface of galvanized steel wire is smooth, smooth, without cracks, knots, punctures, scars and rust, and the galvanized layer is uniform, strong adhesion, long-lasting corrosion resistance, and excellent toughness and elasticity. The tensile strength should be between 900Mpa and 2200Mpa (wire diameter Φ0.2mm-Φ4.4mm). The number of twists (Φ0.5mm) should be more than 20 times, and the repeated bending times should be more than 13 times.

The thickness of the hot-dip zinc layer is 250g/m. The corrosion resistance of the steel wire is greatly improved.

3.Galvanized steel wire is mainly used in the manufacture of planting greenhouses, breeding farms, cotton bales, springs and wire ropes. It is suitable for engineering structures with harsh environmental conditions such as steel cables and sewage pools of cable-stayed bridges

Product Parameters

| Material | Q195/Sae1006/Sae1008/Sea1020 |

| Tolerance | ±5% |

| Standard | ASTM/GB |

| Processing services | Cutting/Bending |

| Shipping date | 15-21days |

| Price terms | FOB/CFR/CIF/EXW/ETC |

| Application | Construction |

| Package | Standard Sea-worthy Packing |

| Galvanized steel wire | |||||

| Diameter (mm) | Tolerance (mm) | Tensile Strength No Less Than (MPA) | Torsion Test No less Than (times) | Bend Times No Less Than (times) | Zinc Coating Mass No Less Than (g/m2) |

| 0.45 | +/-0.01 | 1770 | 28 | 5 | 5 |

| 0.5 | +/-0.01 | 1770 | 28 | 5 | 5 |

| 0.6 | +/-0.01 | 1770 | 28 | 9 | 5 |

| 0.7 | +/-0.01 | 1670 | 28 | 7 | 10 |

| 0.8 | +/-0.01 | 1670 | 28 | 13 | 10 |

| 0.9 | +/-0.02 | 1570 | 28 | 11 | 15 |

| 1 | +/-0.02 | 1470 | 27 | 9 | 20 |

| 1.2 | +/-0.02 | 1470 | 27 | 15 | 20 |

| 1.3 | +/-0.02 | 1370 | 27 | 13 | 20 |

| 1.4 | +/-0.02 | 1370 | 27 | 11 | 20 |

| 1.6 | +/-0.03 | 1370 | 27 | 13 | 20 |

| 1.8 | +/-0.03 | 1370 | 27 | 11 | 30 |

| 2 | +/-0.03 | 1270 | 25 | 10 | 30 |

| 2.4 | +/-0.03 | 1270 | 25 | 11 | 30 |

| 2.6 | +/-0.03 | 1270 | 25 | 10 | 35 |

| 2.77 | +/-0.03 | 1270 | 25 | 9 | 35 |

Production Flow Chart

Project Case

Pack And Ship

Service Process

Our steel products strictly follow international standards, not only to meet the requirements of foreign trade exports, but also to meet the national standard, European standard, American standard and other strict standards.

We promise that each batch of products is carefully selected and rigorously tested to ensure that its quality is excellent, and it can be applied to precision machinery manufacturing, large-scale infrastructure construction and other fields to meet the most demanding needs.

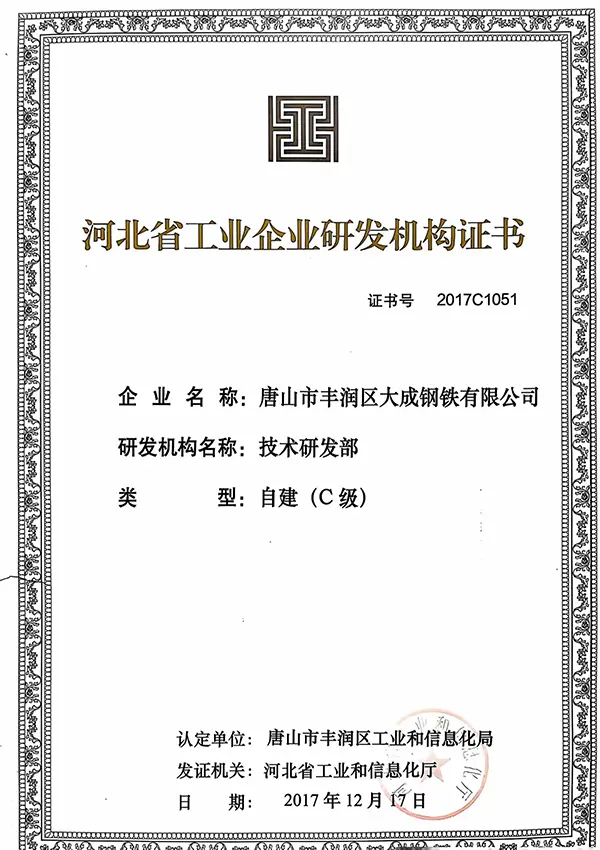

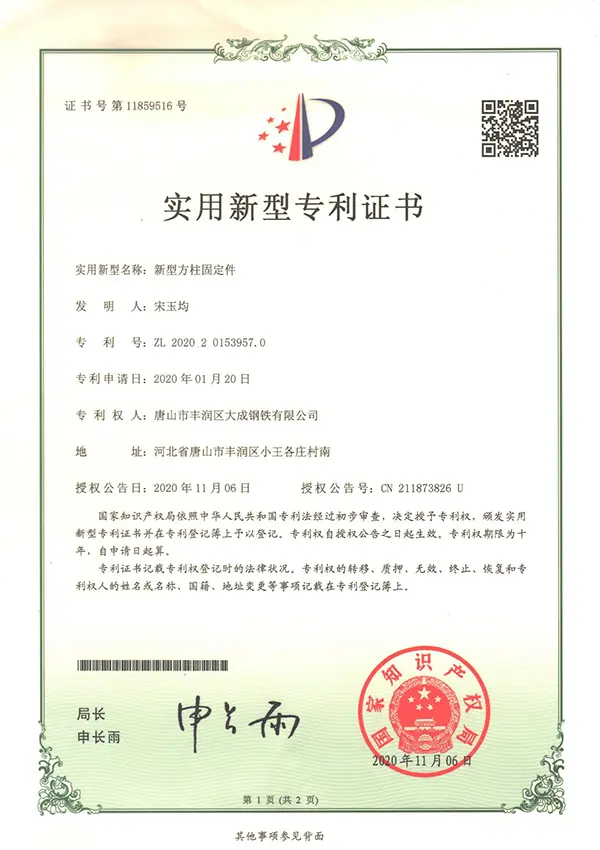

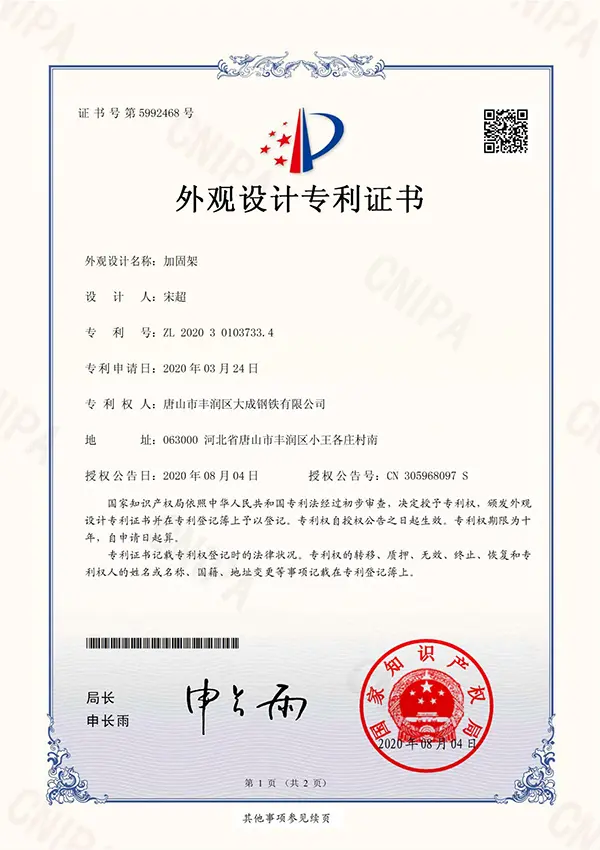

Certificate

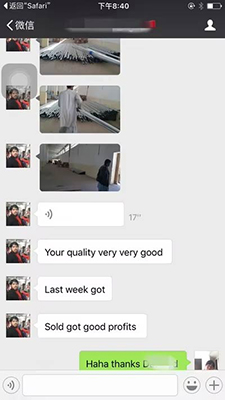

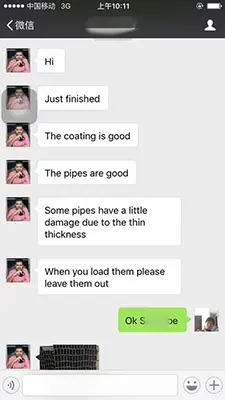

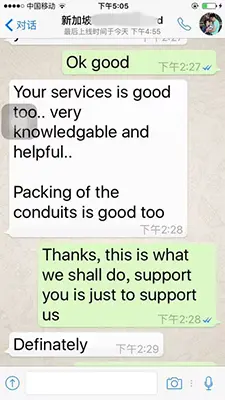

Customer Praise

Plant And Equipment

We have advanced production equipment and a professional technical team. From raw material procurement to product production and global sales, we have achieved seamless full-process management.

FAQ

Q: Can you send samples?

A: Of course, we can send samples to all over the world, our samples are free, but customers need to afford the express cost.

Q: What product information do I need to provide?

A: You need to provide the grade, size and quantity you need to purchase.

Q: What shipping ports are there?

A: Generally, we ship from Shanghai, Tianjin, Qingdao ports, and other ports can also be selected according to your needs.

Q: About the product price?

A: Due to the cyclical changes in raw material prices, prices vary in different periods.

Q: What certifications do your products have?

A: We have ISO 9001, SGS, CE and other certifications.

Q: How do you ship the goods and how long does it take to arrive?

A: Samples are usually shipped by DHL, UPS, FedEx or TNT. Airline and sea transportation are also optional, we will provide you with the fastest transportation plan according to the situation.

Q: Can I visit your factory?

A: Of course, we welcome customers from all over the world to visit our factory.

Q:Is there any quality inspection before product loading?

A: Of course, all of our products have been strictly inspected for quality before packaging, and unqualified products will be

destroyed.

Q: How is the product packaged?

A: The inner layer has waterproof paper and the outer layer has iron packaging, and it is fixed with fumigated wooden pallets. it can Effectively protect products from corrosion during ocean transportation. Of course, we can also customize special packaging according to your requirements.