Annealed Rebar Iron Tie Wire 16 Gauge Galvanized Iron Wire

Product Description

First, the structure of the wire rope

The wire rope structure is made of steel core and steel wire braiding, which is mainly divided into two types: single-strand wire rope and multi-strand wire rope, and the latter is commonly used. Single-strand wire ropes are made from a single wire twisted together, which has a relatively low load capacity and focuses on flexibility and toughness. Multi-strand wire ropes are made by twisting several strands of wire, which has a high load capacity but is also stiffer than single-strand wire ropes. Therefore, in the specific application, it is necessary to select the appropriate wire rope structure according to the requirements of the field.

Second, the classification of wire rope

According to the structure of the wire rope and the different use environment, it can be divided into various types. For example, in terms of structural form, there are core wire ropes, smooth wire ropes, spiral wire ropes and so on. According to the use environment, it can be divided into ordinary wire ropes, wire ropes for anchor chains, wire ropes for cranes, etc.

3. The manufacturing process of wire rope

The manufacturing process of wire rope is very cumbersome and complex, and generally needs to go through multiple processes such as drafting, twisting, preforming, wire strand braiding, impregnation and degreasing, twisting, and forging processing. It is important to note that the drafting process is carried out to stretch the wire within a fixed temperature range, thus changing its mechanical properties and microstructure. This operation is one of the most critical links in the entire wire rope manufacturing.

Fourth, the application field of wire rope

As a widely used load transmission device, wire rope has a wide range of applications. For example, it can be used in cranes, ships, bridges, roads, mines, oil and other fields. Among them, crane wire rope is one of the most widely used and important areas, which is related to the function and quality of crane equipment, and plays a non-negligible role in production safety and operational efficiency. Wire ropes on railway bridges are also a challenging area, especially for bridges hundreds of meters long and large spans, the quality and safety requirements of wire ropes are more stringent.

Product Parameters

| Material | Q195/Sae1006/Sae1008/Sea1020 |

| Tolerance | ±5% |

| Standard | ASTM/GB |

| Processing services | Cutting/Bending |

| Shipping date | 15-21days |

| Price terms | FOB/CFR/CIF/EXW/ETC |

| Application | Construction |

| Package | Standard Sea-worthy Packing |

| Galvanized steel wire | |||||

| Diameter (mm) | Tolerance (mm) | Tensile Strength No Less Than (MPA) | Torsion Test No less Than (times) | Bend Times No Less Than (times) | Zinc Coating Mass No Less Than (g/m2) |

| 0.45 | +/-0.01 | 1770 | 28 | 5 | 5 |

| 0.5 | +/-0.01 | 1770 | 28 | 5 | 5 |

| 0.6 | +/-0.01 | 1770 | 28 | 9 | 5 |

| 0.7 | +/-0.01 | 1670 | 28 | 7 | 10 |

| 0.8 | +/-0.01 | 1670 | 28 | 13 | 10 |

| 0.9 | +/-0.02 | 1570 | 28 | 11 | 15 |

| 1 | +/-0.02 | 1470 | 27 | 9 | 20 |

| 1.2 | +/-0.02 | 1470 | 27 | 15 | 20 |

| 1.3 | +/-0.02 | 1370 | 27 | 13 | 20 |

| 1.4 | +/-0.02 | 1370 | 27 | 11 | 20 |

| 1.6 | +/-0.03 | 1370 | 27 | 13 | 20 |

| 1.8 | +/-0.03 | 1370 | 27 | 11 | 30 |

| 2 | +/-0.03 | 1270 | 25 | 10 | 30 |

| 2.4 | +/-0.03 | 1270 | 25 | 11 | 30 |

| 2.6 | +/-0.03 | 1270 | 25 | 10 | 35 |

| 2.77 | +/-0.03 | 1270 | 25 | 9 | 35 |

Production Flow Chart

Project Case

Pack And Ship

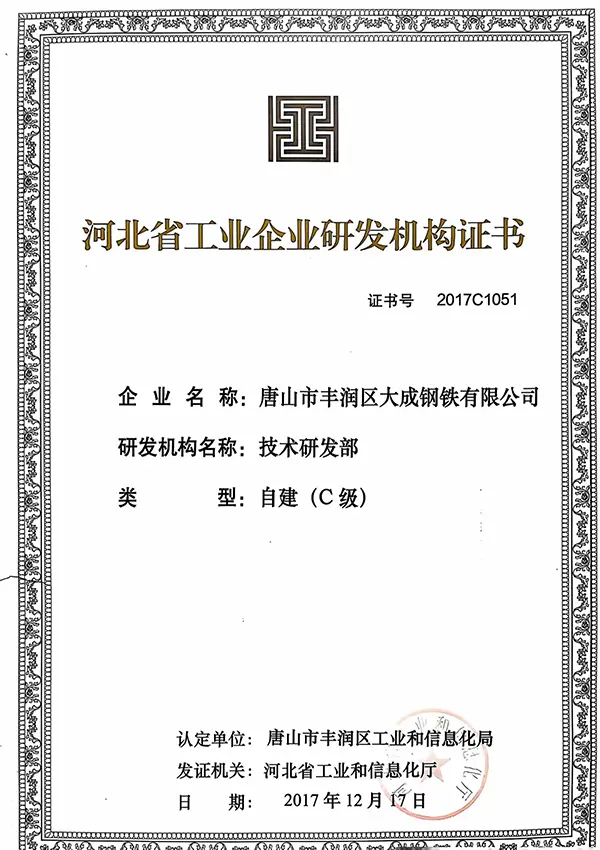

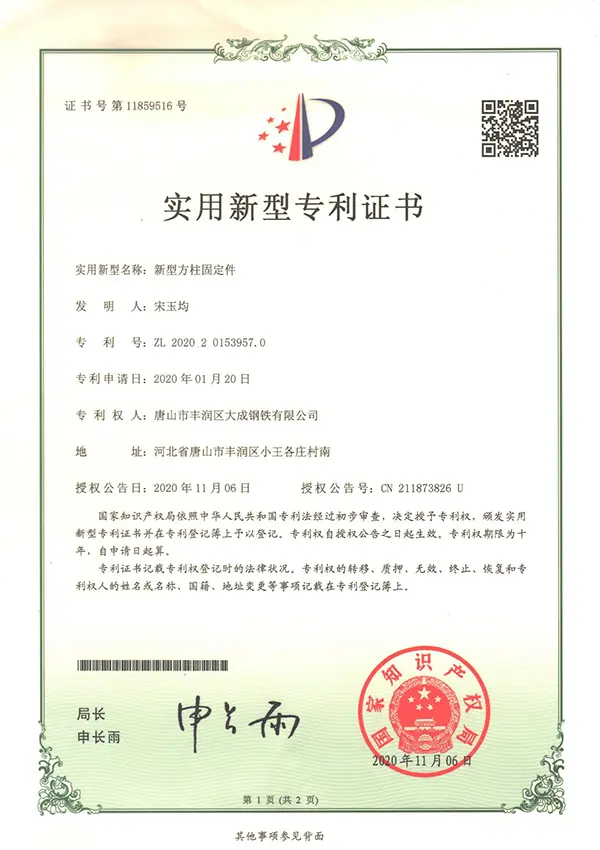

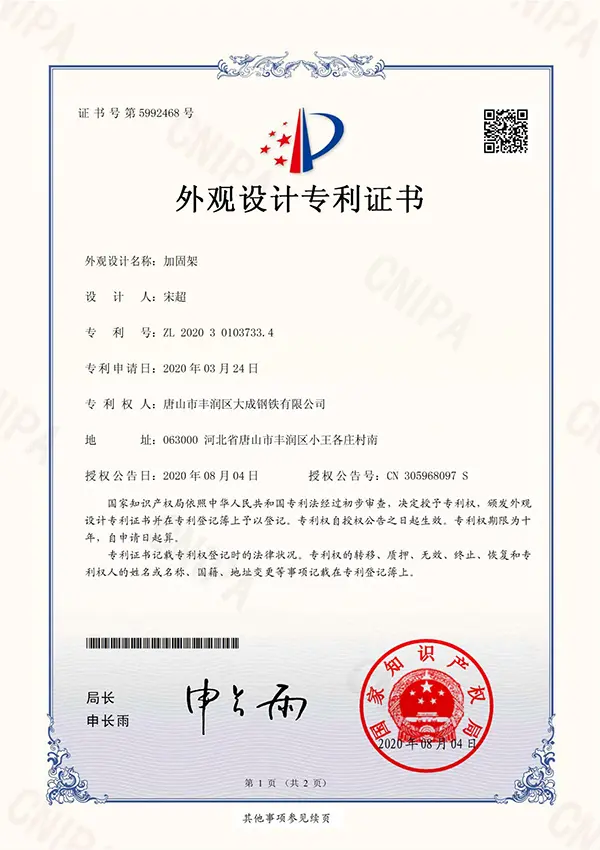

Certificate

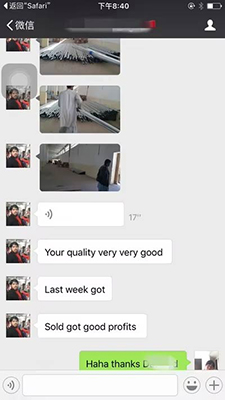

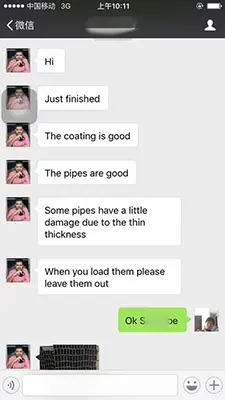

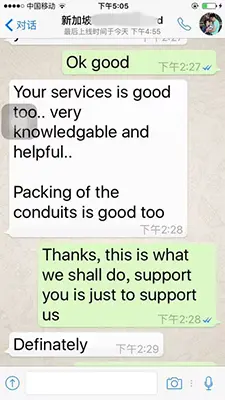

Customer Praise

Plant And Equipment

FAQ

Q1: Do you offer free samples?

A: Sure,we are glad to send you free samples for your evaluation.But currently we need you to kindly pay the delivery charge on your side if you'd like to have our samples.

Q2:How long does your delivery time take?

A:In general, our delivery time is within 7 days, and may be longer if the quantity is extremely large or special circumstances occur.

Q3:Can I go to your factory to visit?

A:Of course, we welcome customers from all over the world to visit our factory.

Q4:Does the product have quality inspection before loading?

A:Of course, all our products are strictly tested for quality before packaging, and unqualified products will be destroyed and customers can appoint third parties to inspect the products before loading too.

Q5:How to pack the products?

A: Standard export sea-worthy packaging, the inner layer has a waterproof paper outer layer with iron packaging and is fixed with a fumigation wooden pallet. It can effectively protect products from corrosion and various climate changes during ocean transportation.

Q6: How to order?

A: Buyer sends the enquery --> Buyer gets the quotation --> Order confirmation --> Buyer send the deposit --> Seller prepares goods --> Seller makes the strict inspection --> Buyer Arranges Balance Payment --> packing and delivery