Oem Odm 1.6mm Galvanized Steel Wire Low Price Galvanized Steel Wire High Quality Galvanized Steel Wire for Hangers

Product Description

Galvanized steel wire is made by drawing high-quality carbon structural steel such as 45#, 65#, 70#, 80#, 90#, and then heat treating and galvanizing. It is mainly used for the manufacture of galvanized steel wire mesh, construction engineering, springs and various steel wire ropes. According to different uses and processing methods, galvanized steel wire can be divided into hot-dip, electroplating, mechanical plating, cold plating and other types. At present, there are two methods for galvanizing steel wire: multi-line continuous hot-dip and electroplating. Electrogalvanizing is obtained by applying an external power source and using electrodeposition to obtain a coating. The obtained coating is composed of fine pure zinc grains. Hot-dip galvanizing (see hot-dip galvanizing of steel wire) forms a coating by physical thermal diffusion. First, an iron-zinc compound is formed, and then a pure zinc layer is generated on the surface of the iron-zinc compound. Hot-dip galvanizing will reduce the mechanical properties of the steel wire. Galvanized steel wire ropes that require high strength and high corrosion resistance are mostly twisted with electrogalvanized steel wire. The mainstream products on the market include galvanized steel wire heat-treated state, galvanized steel wire drawn state, micro rope, etc.

Measures to be taken: improve the design, adjust the tooling, ensure that the steel wire positioned by the wire roller of the finale and the lead frame is perpendicular to the liquid level of zinc, and when the finale is worn, the position of the wire roller must be adjusted in time or the finale must be rotated to ensure that the steel wire is perpendicular to the liquid level. The charcoal particles should be evenly wiped and compacted. Zinc should be added far away from the lead and slowly pushed in, the position of the finale to the operating surface of the zinc pot should not be too close, and it is best to have a tension control device on the production line to prevent the fluctuation of the zinc liquid level.

Product Parameters

| Material | Q195/Sae1006/Sae1008/Sea1020 |

| Tolerance | ±5% |

| Standard | ASTM/GB |

| Processing services | Cutting/Bending |

| Shipping date | 15-21days |

| Price terms | FOB/CFR/CIF/EXW/ETC |

| Application | Construction |

| Package | Standard Sea-worthy Packing |

| Galvanized steel wire | |||||

| Diameter (mm) | Tolerance (mm) | Tensile Strength No Less Than (MPA) | Torsion Test No less Than (times) | Bend Times No Less Than (times) | Zinc Coating Mass No Less Than (g/m2) |

| 0.45 | +/-0.01 | 1770 | 28 | 5 | 5 |

| 0.5 | +/-0.01 | 1770 | 28 | 5 | 5 |

| 0.6 | +/-0.01 | 1770 | 28 | 9 | 5 |

| 0.7 | +/-0.01 | 1670 | 28 | 7 | 10 |

| 0.8 | +/-0.01 | 1670 | 28 | 13 | 10 |

| 0.9 | +/-0.02 | 1570 | 28 | 11 | 15 |

| 1 | +/-0.02 | 1470 | 27 | 9 | 20 |

| 1.2 | +/-0.02 | 1470 | 27 | 15 | 20 |

| 1.3 | +/-0.02 | 1370 | 27 | 13 | 20 |

| 1.4 | +/-0.02 | 1370 | 27 | 11 | 20 |

| 1.6 | +/-0.03 | 1370 | 27 | 13 | 20 |

| 1.8 | +/-0.03 | 1370 | 27 | 11 | 30 |

| 2 | +/-0.03 | 1270 | 25 | 10 | 30 |

| 2.4 | +/-0.03 | 1270 | 25 | 11 | 30 |

| 2.6 | +/-0.03 | 1270 | 25 | 10 | 35 |

| 2.77 | +/-0.03 | 1270 | 25 | 9 | 35 |

Production Flow Chart

Project Case

Pack And Ship

Certificate

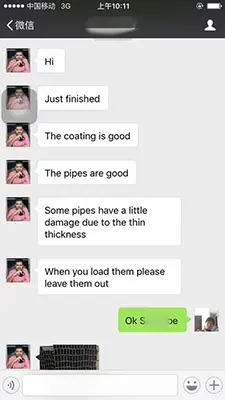

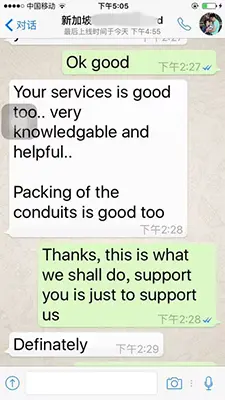

Customer Praise

Plant And Equipment

FAQ

Q:What are the shipping ports?

A:You can choose other ports according to your needs.

Q:About product prices?

A:Prices vary from period to period due to cyclical changes in the price of raw materials.

Q:What are the certifications for your products?

A:We have ISO 9001,EWC and other certifications.

Q:How long does your delivery time take?

A:In general, our delivery time is within 7-45 days, and may be delayed if the demand is

extremely large or special circumstances occur.

Q:Can I go to your factory to visit?

A:Of course, we welcome customers from all over the world to visit our factory.

Q:Does the product have quality inspection before loading?

A:Of course, all our products are strictly tested for quality before packaging.

Q:What is your working time?

A:In general, our online service time is: 9:00-22:00, after 22:00, we will reply to your

inquiry during the next working day.