Steel Wire Rod SAE 1008 1006 0.3mm 6.5mm ASTM 14 Gauge Hot Dipped Galvanized Steel Wire for Manufuacturing Building Packaging

Product Description

Plating and then drawing process: In order to improve the performance of galvanized steel wire, the process of drawing the steel wire to the finished product after lead fire and galvanization is called the first plating and then drawing process. The typical process flow is: steel wire - lead quenching - galvanizing - drawing - finished steel wire. The first plating and then drawing process is one of the shortest process among the galvanized steel wire drawing methods, which can be used for hot-dip galvanizing or electro-galvanizing and then drawing. The mechanical properties of hot-dip galvanized post-drawing are better than those of steel wire after drawing, and the zinc layer is dense and resistant after electro-galvanizing. Both can obtain a thin and uniform zinc layer, which reduces zinc consumption and reduces the load on the galvanizing line.

Medium plating and post-drawing process: The process flow of medium plating and post-drawing is: steel wire - lead quenching - primary drawing - galvanizing - secondary drawing - finished steel wire. The characteristics of the post-plating drawing are that the lead quenched steel wire is galvanized after a drawing and then drawn to the finished product twice, and the galvanizing is between the two drawings, so it is called 'medium plating,. The zinc layer of steel wire produced by medium plating and then drawing is thicker than that of plating first and then drawing. Hot-dip galvanizing can give a high total compression ratio (from lead quenching to finished product) and better performance than steel wire plating and then drawing.

Hybrid Plating Process: For the production of ultra-high strength (3000 N/mm²) galvanized steel wire, the "Hybrid Plating" process is used. The typical process flow is as follows: lead quenching - one drawing - pre-galvanizing - secondary drawing - final galvanizing - three drawing (dry drawing) - water tank drawing a finished steel wire. The above process can produce ultra-high-strength galvanized steel wire containing 0.93-0.97% carbon, with a diameter of 0.26 mm and a strength of 3921 N/sq mm. The zinc layer protects and lubricates the surface of the steel wire during drawing, and there is no broken wire during drawing

Product Parameters

| Material | Q195/Sae1006/Sae1008/Sea1020 |

| Tolerance | ±5% |

| Standard | ASTM/GB |

| Processing services | Cutting/Bending |

| Shipping date | 15-21days |

| Price terms | FOB/CFR/CIF/EXW/ETC |

| Application | Construction |

| Package | Standard Sea-worthy Packing |

| Galvanized steel wire | |||||

| Diameter (mm) | Tolerance (mm) | Tensile Strength No Less Than (MPA) | Torsion Test No less Than (times) | Bend Times No Less Than (times) | Zinc Coating Mass No Less Than (g/m2) |

| 0.45 | +/-0.01 | 1770 | 28 | 5 | 5 |

| 0.5 | +/-0.01 | 1770 | 28 | 5 | 5 |

| 0.6 | +/-0.01 | 1770 | 28 | 9 | 5 |

| 0.7 | +/-0.01 | 1670 | 28 | 7 | 10 |

| 0.8 | +/-0.01 | 1670 | 28 | 13 | 10 |

| 0.9 | +/-0.02 | 1570 | 28 | 11 | 15 |

| 1 | +/-0.02 | 1470 | 27 | 9 | 20 |

| 1.2 | +/-0.02 | 1470 | 27 | 15 | 20 |

| 1.3 | +/-0.02 | 1370 | 27 | 13 | 20 |

| 1.4 | +/-0.02 | 1370 | 27 | 11 | 20 |

| 1.6 | +/-0.03 | 1370 | 27 | 13 | 20 |

| 1.8 | +/-0.03 | 1370 | 27 | 11 | 30 |

| 2 | +/-0.03 | 1270 | 25 | 10 | 30 |

| 2.4 | +/-0.03 | 1270 | 25 | 11 | 30 |

| 2.6 | +/-0.03 | 1270 | 25 | 10 | 35 |

| 2.77 | +/-0.03 | 1270 | 25 | 9 | 35 |

Production Flow Chart

Project Case

Pack And Ship

Certificate

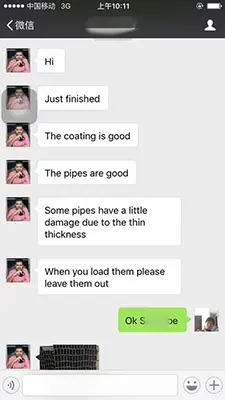

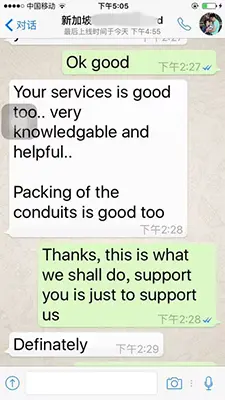

Customer Praise

Plant And Equipment

FAQ

Q: Why should I choose you?

A: Choose happens because of quality,then price, we can give you both. Additionally, we can also offer professional products inquiry, products knowledge train( for agents), smooth goods delivery, excellent customer solution proposals.

Our service formula:good quality + good price + good service = Customer's trust

Q: How long is your delivery time?

A: Generally it is 10 days if the goods are in stock. or it is 30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: We accept LC and TT both.