High quality custom specifications Hot dip galvanizing wire 10 12 14 16 18 specifications

Product Description

Galvanized wire

Wire drawing: Select a steel wire of appropriate diameter for drawing to the target diameter.

Annealing: The steel wire after drawing is subjected to high temperature annealing treatment to improve toughness and ductility.

Pickling: The oxide layer and dirt on the surface of the steel wire are removed by pickling.

Galvanizing: Galvanizing is carried out according to hot-dip or cold-dip methods to form a zinc layer. Hot-dip galvanizing is to immerse the steel wire in molten zinc liquid; cold-dip galvanizing is to evenly attach zinc to the surface of the steel wire through electrolytic reaction.

Galvanized iron wire: hot-dip galvanized iron wire, electro-galvanized iron wire (large rolls, small rolls/rolls)

Features:

1. Excellent flexibility and softness

2. Suitable for use: woven mesh, fences, concrete bundling or wood bundling for construction, packaging, hanging, etc.

Hot-dip galvanized iron wire

Hot-dip galvanized iron wire is made of low-carbon steel wire, which is drawn and pickled

Rust removal, annealing, galvanizing, and coiling. Mainly used in construction, handicrafts,

woven nets, highway guardrail nets, product packaging and other daily uses.

Product Parameters

| Material | Q195/Sae1006/Sae1008/Sea1020 |

| Tolerance | ±5% |

| Standard | ASTM/GB |

| Processing services | Cutting/Bending |

| Shipping date | 15-21days |

| Price terms | FOB/CFR/CIF/EXW/ETC |

| Application | Construction |

| Package | Standard Sea-worthy Packing |

| Galvanized steel wire | |||||

| Diameter (mm) | Tolerance (mm) | Tensile Strength No Less Than (MPA) | Torsion Test No less Than (times) | Bend Times No Less Than (times) | Zinc Coating Mass No Less Than (g/m2) |

| 0.45 | +/-0.01 | 1770 | 28 | 5 | 5 |

| 0.5 | +/-0.01 | 1770 | 28 | 5 | 5 |

| 0.6 | +/-0.01 | 1770 | 28 | 9 | 5 |

| 0.7 | +/-0.01 | 1670 | 28 | 7 | 10 |

| 0.8 | +/-0.01 | 1670 | 28 | 13 | 10 |

| 0.9 | +/-0.02 | 1570 | 28 | 11 | 15 |

| 1 | +/-0.02 | 1470 | 27 | 9 | 20 |

| 1.2 | +/-0.02 | 1470 | 27 | 15 | 20 |

| 1.3 | +/-0.02 | 1370 | 27 | 13 | 20 |

| 1.4 | +/-0.02 | 1370 | 27 | 11 | 20 |

| 1.6 | +/-0.03 | 1370 | 27 | 13 | 20 |

| 1.8 | +/-0.03 | 1370 | 27 | 11 | 30 |

| 2 | +/-0.03 | 1270 | 25 | 10 | 30 |

| 2.4 | +/-0.03 | 1270 | 25 | 11 | 30 |

| 2.6 | +/-0.03 | 1270 | 25 | 10 | 35 |

| 2.77 | +/-0.03 | 1270 | 25 | 9 | 35 |

Production Flow Chart

Project Case

Pack And Ship

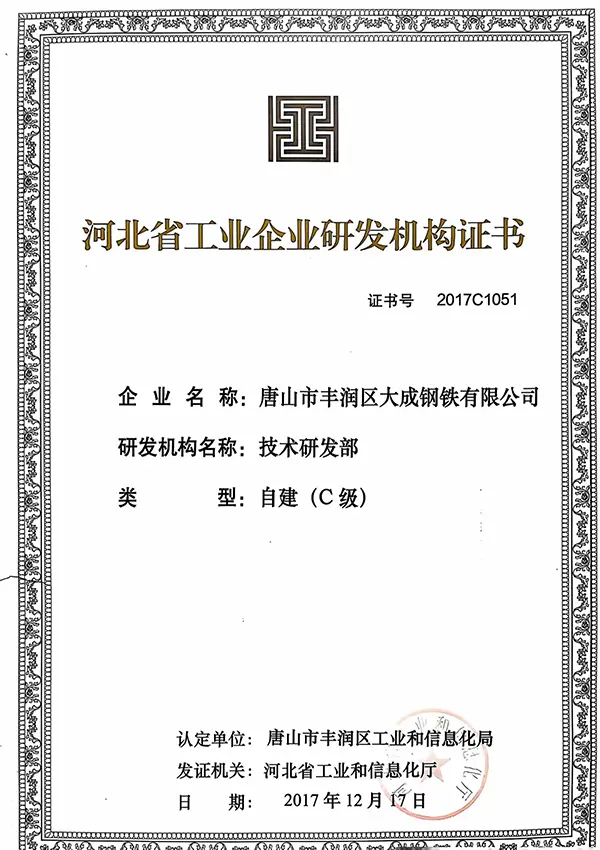

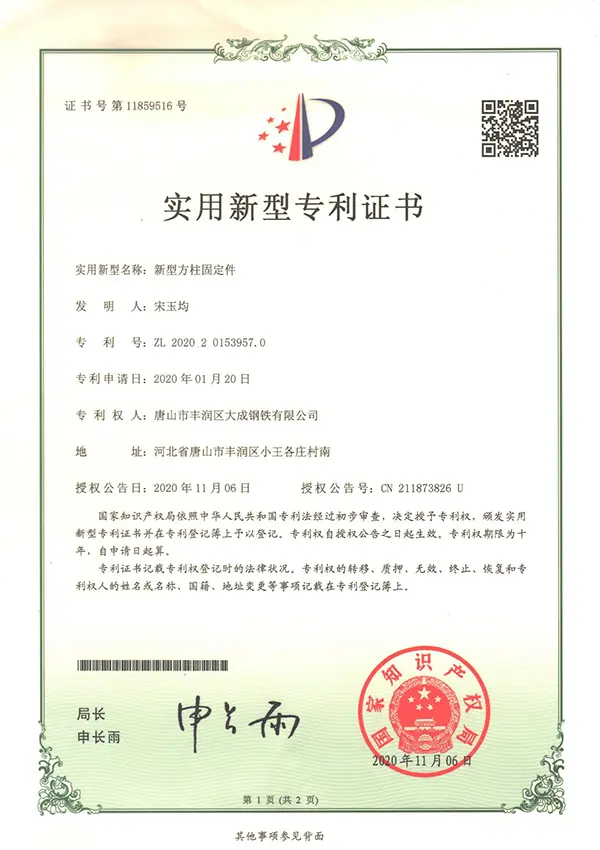

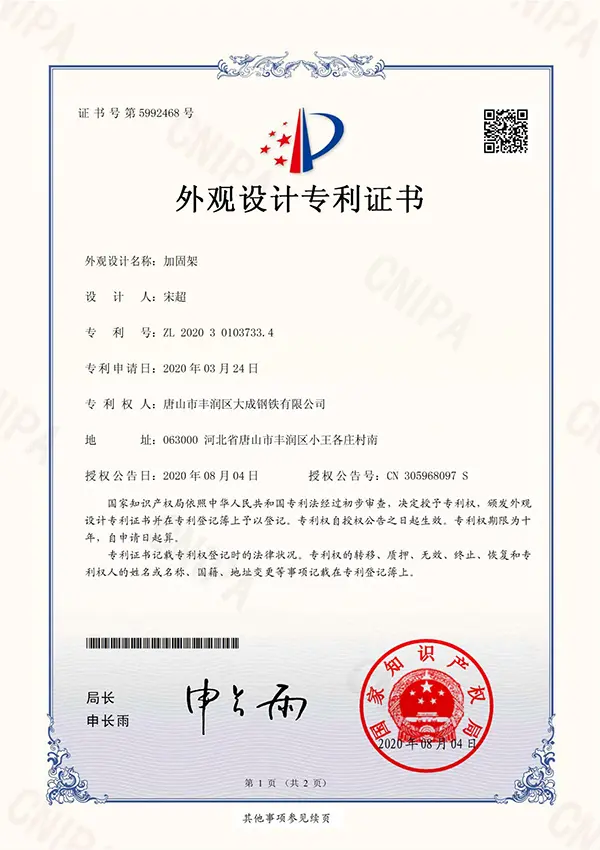

Certificate

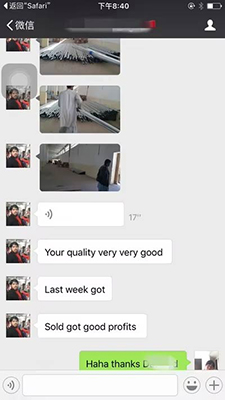

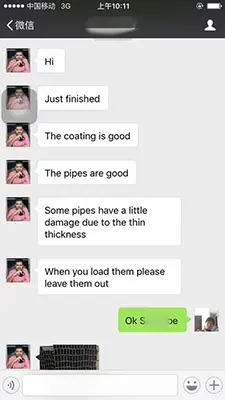

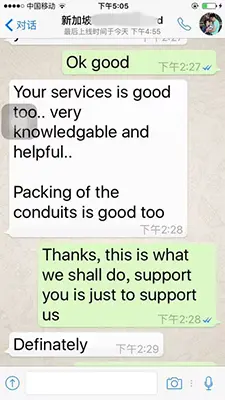

Customer Praise

Plant And Equipment

FAQ

Q1: How do you guarantee the quality?

A1: ①We have passed ISO9001, SGS, CE and other certifications;

②Always have pre-production samples before mass production, and always do final inspection before shipment;

③Acceptable third-party inspection.

Q2: Can you arrange the shipment?

A2: Sure, we have permanent freight forwarder who can gain the best price from most ship company and offer professional service.

Q3: How long is your delivery time?

A3: Generally it is 7-14 days if the goods are in stock. or it is 25-45 days if the goods are not in stock, it is according to quantity.

Q4:How can we get the offer?

A4:Please offer the specification of the product,such as material,size,shape,etc. So wecan give the best offer.

Q5:How can I get one sample for testing?

A5:Free sample: We'd love to send you free samples which have in stock, and you just need arrange shipment.

Charged sample: $100 for sample developed, and return after mass production

Q6: How do you make our business long-term and good relationship?

A6: (1)We keep good quality and competitive price to ensure our customers' benefit.

(2) We respect every customer as our friend and we sincerrly do business and make friends with them, no matter where they come from.