ASTM Standard Galvanized Steel Tie Wire Reel Construction GI Wire Spool for Rebar Binding Welding Cutting Services Includes

Product Description

For galvanized steel wire, the requirement of coating uniformity is that the coating is uniform on the transverse (radial) section, and the coating layer of each cross-section of the steel wire is almost the same in the longitudinal (axial) direction. The accumulation of local zinc layer on the surface of the steel wire (commonly known as zinc tumor) caused by the shaking of the steel wire, the fluctuation of the zinc liquid level, and the scum on the surface of the plating pot should be eliminated by correcting the tooling and standardizing the operation. Regardless of these random and irregular zinc layer accumulation, under the condition of determining the tooling, stable process and the same operating specification, the zinc layer of each section on the full length of the steel wire will not be much different, so a cross-section perpendicular to the steel wire and without zinc layer accumulation can be selected for the evaluation of coating uniformity.

Galvanized steel wire: The surface of galvanized steel wire is smooth, bright, without cracks, knots, thorns, scars and rust. The galvanized layer is uniform, has strong adhesion, long-lasting corrosion resistance, and excellent toughness and elasticity. The tensile strength should be between 900Mpa-2200Mpa (wire diameter Φ0.2mm-Φ4.4mm). The number of twists (Φ0.5mm) should be more than 20 times, and the repeated bending should be more than 13 times. The thickness of the hot-dip zinc layer is 250g/m. The corrosion resistance of the steel wire is greatly improved. Galvanized steel wire is mainly used for greenhouses, farms, cotton packaging, springs and wire ropes. It is suitable for engineering structures with harsh environmental conditions such as cable-stayed bridge cables and sewage pools.

Product Parameters

| Material | Q195/Sae1006/Sae1008/Sea1020 |

| Tolerance | ±5% |

| Standard | ASTM/GB |

| Processing services | Cutting/Bending |

| Shipping date | 15-21days |

| Price terms | FOB/CFR/CIF/EXW/ETC |

| Application | Construction |

| Package | Standard Sea-worthy Packing |

| Galvanized steel wire | |||||

| Diameter (mm) | Tolerance (mm) | Tensile Strength No Less Than (MPA) | Torsion Test No less Than (times) | Bend Times No Less Than (times) | Zinc Coating Mass No Less Than (g/m2) |

| 0.45 | +/-0.01 | 1770 | 28 | 5 | 5 |

| 0.5 | +/-0.01 | 1770 | 28 | 5 | 5 |

| 0.6 | +/-0.01 | 1770 | 28 | 9 | 5 |

| 0.7 | +/-0.01 | 1670 | 28 | 7 | 10 |

| 0.8 | +/-0.01 | 1670 | 28 | 13 | 10 |

| 0.9 | +/-0.02 | 1570 | 28 | 11 | 15 |

| 1 | +/-0.02 | 1470 | 27 | 9 | 20 |

| 1.2 | +/-0.02 | 1470 | 27 | 15 | 20 |

| 1.3 | +/-0.02 | 1370 | 27 | 13 | 20 |

| 1.4 | +/-0.02 | 1370 | 27 | 11 | 20 |

| 1.6 | +/-0.03 | 1370 | 27 | 13 | 20 |

| 1.8 | +/-0.03 | 1370 | 27 | 11 | 30 |

| 2 | +/-0.03 | 1270 | 25 | 10 | 30 |

| 2.4 | +/-0.03 | 1270 | 25 | 11 | 30 |

| 2.6 | +/-0.03 | 1270 | 25 | 10 | 35 |

| 2.77 | +/-0.03 | 1270 | 25 | 9 | 35 |

Production Flow Chart

Project Case

Pack And Ship

Certificate

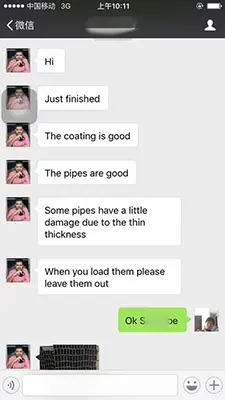

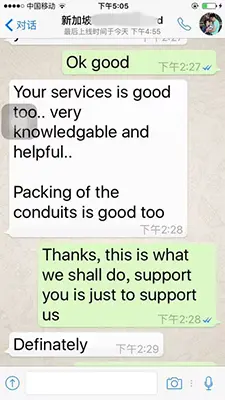

Customer Praise

Plant And Equipment