Spring Wire SAE1008 SAE1006 S45c Q235 Q195 77b 82b 5.5mm

Product Description

By surface treatment

According to the surface treatment, it is divided into smooth wire rope, galvanized wire rope and plastic-coated wire rope.

Smooth wire rope: refers to the primary color wire rope without any surface treatment, which is characterized by clear structure, high strength, but easy to rust. Smooth wire rope is mainly used for:

Dry or well-lubricated occasions, such as indoor lifting machinery and elevator equipment, etc.

Galvanized steel wire rope: refers to the steel wire rope coated with a layer of zinc layer on the surface of the rope making wire, which is characterized by good corrosion resistance and bright appearance, but slightly lower strength. Galvanized wire ropes are mainly used in wet or marine environments, such as port equipment and marine equipment. Plastic-coated wire rope: refers to the wire rope coated with a plastic layer on the surface of the rope wire or strand rope, which is characterized by excellent corrosion resistance, waterproof, dustproof and pollution-proof, but the lowest strength. Plastic-coated wire ropes are mainly used in situations that come into contact with food or drugs, such as food processing equipment and medical equipment.

Product Parameters

| Material | Q195/Sae1006/Sae1008/Sea1020 |

| Tolerance | ±5% |

| Standard | ASTM/GB |

| Processing services | Cutting/Bending |

| Shipping date | 15-21days |

| Price terms | FOB/CFR/CIF/EXW/ETC |

| Application | Construction |

| Package | Standard Sea-worthy Packing |

| Galvanized steel wire | |||||

| Diameter (mm) | Tolerance (mm) | Tensile Strength No Less Than (MPA) | Torsion Test No less Than (times) | Bend Times No Less Than (times) | Zinc Coating Mass No Less Than (g/m2) |

| 0.45 | +/-0.01 | 1770 | 28 | 5 | 5 |

| 0.5 | +/-0.01 | 1770 | 28 | 5 | 5 |

| 0.6 | +/-0.01 | 1770 | 28 | 9 | 5 |

| 0.7 | +/-0.01 | 1670 | 28 | 7 | 10 |

| 0.8 | +/-0.01 | 1670 | 28 | 13 | 10 |

| 0.9 | +/-0.02 | 1570 | 28 | 11 | 15 |

| 1 | +/-0.02 | 1470 | 27 | 9 | 20 |

| 1.2 | +/-0.02 | 1470 | 27 | 15 | 20 |

| 1.3 | +/-0.02 | 1370 | 27 | 13 | 20 |

| 1.4 | +/-0.02 | 1370 | 27 | 11 | 20 |

| 1.6 | +/-0.03 | 1370 | 27 | 13 | 20 |

| 1.8 | +/-0.03 | 1370 | 27 | 11 | 30 |

| 2 | +/-0.03 | 1270 | 25 | 10 | 30 |

| 2.4 | +/-0.03 | 1270 | 25 | 11 | 30 |

| 2.6 | +/-0.03 | 1270 | 25 | 10 | 35 |

| 2.77 | +/-0.03 | 1270 | 25 | 9 | 35 |

Production Flow Chart

Project Case

Pack And Ship

Certificate

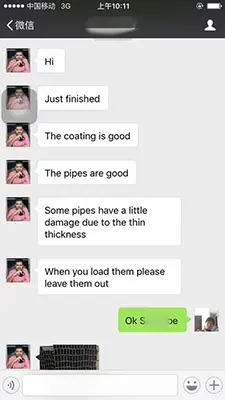

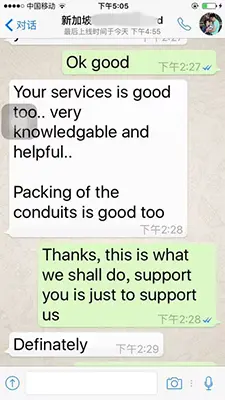

Customer Praise

Plant And Equipment

FAQ

Q1. Where is your factory ?

A1: Our company’s processing center is located in Tangshan, Hebei, China.

Which is well equipped with kinds of machines, such as laser cutting machine,mirror polishing machine and so on.We can provide a wide range of personalized services according to the customers’ needs.

Q2. What are your company's main products ?

A2: Our main products are stainless steel plate/sheet, coil, round/square pipe, bar, channel, etc.

Q3. How do you control quality ?

A3: Mill Test Certification is supplied with shipment, Third Party Inspection is available.

Q4. What are the advantages of your company ?

A4: We have many professionals, technical personnel, more competitive prices and best after-dales service than other stainless steel companies.

Q5. How many coutries you already exported ?

A5: Exported to more than 50 countries mainly from America, Russia, UK, Kuwait, Egypt, Turkey, Jordan,

India, etc.

Q6. Can you provide sample ?

A6: Small samples in store and can provide the samples for free.

Customized samples will take about 5-7days.