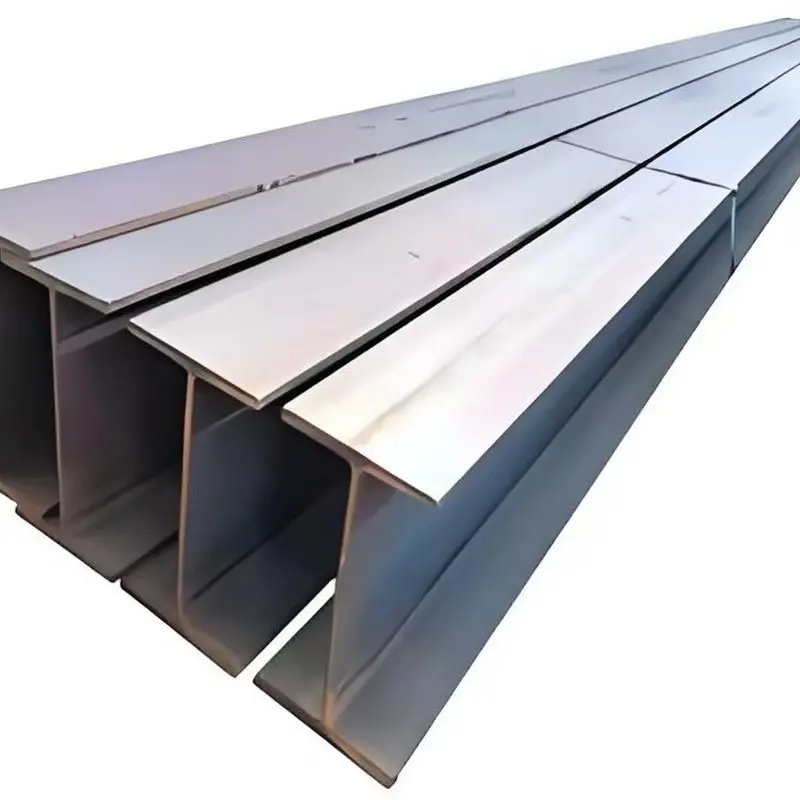

A572 Grade 50 I-Beams JIS Standard W 200 X 52 20ft Hot Rolled Steel H Beam for Construction Bending Cutting Welding

Product Description

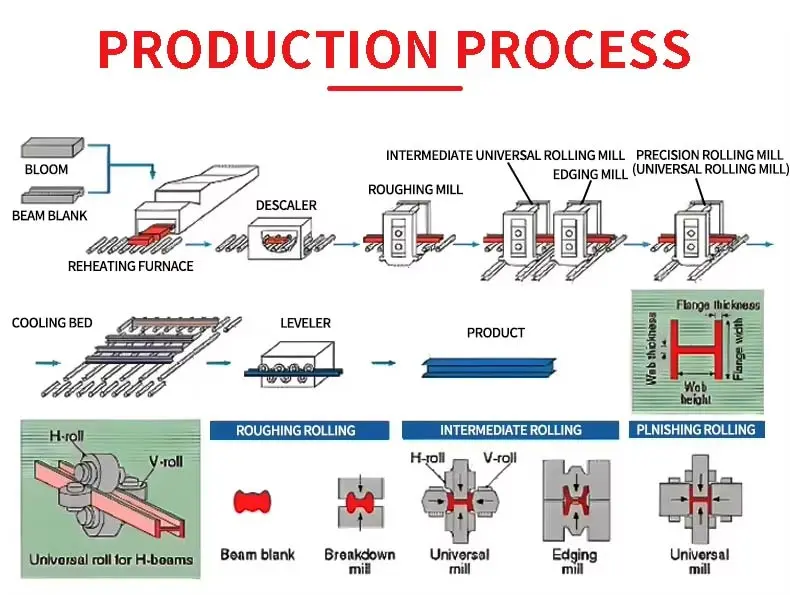

H-beam can be produced by welding or rolling. Welded H-beam is to cut the strip steel of appropriate thickness into appropriate width, and weld the flange and web together on a continuous welding unit. Welded H-beam has the disadvantages of high metal consumption, difficulty in ensuring uniform product performance, and limited size specifications. Therefore, H-beam is mainly produced by rolling. In modern steel rolling production, universal rolling mills are used to roll H-beam.

The web of H-beam is rolled between the upper and lower horizontal rollers, and the flange is rolled and formed simultaneously between the side of the horizontal roller and the vertical roller. Since the flange end cannot be pressed down by the universal rolling mill alone, it is necessary to set an edge rolling machine, commonly known as an edge rolling machine, behind the universal frame to press down the flange end and control the flange width.

In actual rolling operations, these two stands are used as a group to make the workpiece reciprocate several times (Figure 2a), or the workpiece is passed through a continuous rolling mill consisting of several universal stands and one or two edge rolling stands. A certain amount of reduction is applied each time to roll the billet into a product of the required specifications, shape and size. In the flange area of the workpiece, the wear of the rollers is relatively large due to the sliding between the side of the horizontal roller and the workpiece.

In order to ensure that the rollers can restore their original shape after heavy rolling, the side surfaces of the upper and lower horizontal rollers of the rough rolling unit and the corresponding vertical roller surfaces should be inclined at an angle of 3° to 8°. In order to correct the inclination of the finished product flange, a finished product universal rolling mill, also called a universal finishing mill, is set up. The side surfaces of the horizontal rollers are perpendicular to the axis of the horizontal rollers or have a smaller inclination angle, generally not greater than 20′, and the vertical rollers are cylindrical.

The web of H-beam is rolled between the upper and lower horizontal rollers, and the flange is rolled and formed simultaneously between the side of the horizontal roller and the vertical roller. Since the flange end cannot be pressed down by the universal rolling mill alone, it is necessary to set an edge rolling machine, commonly known as an edge rolling machine, behind the universal frame to press down the flange end and control the flange width.

In actual rolling operations, these two stands are used as a group to make the workpiece reciprocate several times (Figure 2a), or the workpiece is passed through a continuous rolling mill consisting of several universal stands and one or two edge rolling stands. A certain amount of reduction is applied each time to roll the billet into a product of the required specifications, shape and size. In the flange area of the workpiece, the wear of the rollers is relatively large due to the sliding between the side of the horizontal roller and the workpiece.

In order to ensure that the rollers can restore their original shape after heavy rolling, the side surfaces of the upper and lower horizontal rollers of the rough rolling unit and the corresponding vertical roller surfaces should be inclined at an angle of 3° to 8°. In order to correct the inclination of the finished product flange, a finished product universal rolling mill, also called a universal finishing mill, is set up. The side surfaces of the horizontal rollers are perpendicular to the axis of the horizontal rollers or have a smaller inclination angle, generally not greater than 20′, and the vertical rollers are cylindrical.

Product Parameters

| GB H beam | JIS H beam | ||||||

| SIZE(mm) | KG/m | SIZE(mm) | KG/m | SIZE(mm) | KG/m | SIZE(mm) | KG/m |

| 100*100*6*8 | 17.2 | 390*300*10*16 | 107 | 100*100*6*8 | 16.9 | 388*402*15*15 | 140 |

| 125'125*6.5*9 | 23.8 | 396*199*7*11 | 56.7 | 125*125*6.5*9 | 23.6 | 390*300*10*16 | 105 |

| 150*75*5*7 | 14.3 | 400*150*8*13 | 55.8 | 150*75*5*7 | 14 | 396*199*7*11 | 56.1 |

| 148*100*6*9 | 21.4 | 400*200*8*13 | 66 | 148*100*6*9 | 20.7 | 400*200*8*13 | 65.4 |

| 150*150*7*10 | 31.9 | 400*400*13*21 | 172 | 150*150*7*10 | 31.1 | 400*150*8*13 | 55.2 |

| 175*90*5*8 | 18.2 | 400*408*21*21 | 197 | 175*90*5*8 | 18 | 400*400*13*21 | 172 |

| 175*175*7.5*11 | 40.4 | 414*405*18*28 | 233 | 175*175*7.5*11 | 40.4 | 400*408*21*21 | 197 |

| 194*150*6*9 | 31.2 | 428*407*20*35 | 284 | 194*150*6*9 | 29.9 | 414*405*18*28 | 232 |

| 198*99*4.5*7 | 18.5 | 440*300*11*18 | 124 | 198*99*4.5*7 | 17.8 | 428*407*20*35 | 283 |

| 200*100*5.5*8 | 21.7 | 446*199*8*12 | 65.5 | 200*100*5.5*8 | 20.9 | 440*300*11*18 | 121 |

| 200*200*8*12 | 50.5 | 450*200*9*14 | 76.5 | 200*200*8*12 | 49.9 | 446*199*8*12 | 65.1 |

| 200*204*12*12 | 56.7 | 482*300*11*15 | 115 | 200*204*12*12 | 56.2 | 450*200*9*14 | 74.9 |

| 244*175*7*11 | 44.1 | 488*300*11*18 | 129 | 244*175*7*11 | 43.6 | 482*300*11*15 | 111 |

| 248*124*5*8 | 25.8 | 496*199*9*14 | 79.5 | 248*124*5*8 | 25.1 | 488*300*11*18 | 125 |

| 250*125*6*9 | 29.7 | 500*200*10*16 | 89.6 | 250*125*6*9 | 29 | 496*199*9*14 | 77.9 |

| 250*250*9*14 | 72.4 | 506*201*11*19 | 103 | 250*250*9*14 | 71.8 | 500*200*10*16 | 88.2 |

| 250*255*14*14 | 82.2 | 582*300*12*17 | 137 | 250*255*14*14 | 81.6 | 506*201*11*19 | 102 |

| 294*200*8*12 | 57.3 | 588*300*12*20 | 151 | 294*200*8*12 | 55.8 | 582*300*12*17 | 133 |

| 294*302*12*12 | 85 | 594*302*14*23 | 175 | 294*302*12*12 | 83.4 | 588*300*12*20 | 147 |

| 298*149*5.5*8 | 32.6 | 596*199*10*15 | 95.1 | 298*149*5.5*8 | 32 | 594*302*14*23 | 170 |

| 298*201*9*14 | 65.4 | 600*200*11*17 | 106 | 300*150*6.5*9 | 36.7 | 596*199*10*15 | 92.5 |

| 300*150*6.5*9 | 37.3 | 606*201*12*20 | 120 | 300*300*10*15 | 93 | 600*200*11*17 | 103 |

| 300*300*10*15 | 94.5 | 692*300*13*20 | 166 | 300*305*15*15 | 105 | 606*201*12*20 | 118 |

| 300*305*15*15 | 106 | 700“300*13-24 | 185 | 340*250*9*14 | 78.1 | 692*300*13*20 | 163 |

| 340*250*9*14 | 79.7 | 792*300*14*22 | 191 | 346*174*6*9 | 41.2 | 700*300*13*24 | 182 |

| 346*174*6*9 | 41.8 | 800*300*14*26 | 210 | 350*175*7*11 | 49.4 | 800*300*14*26 | 207 |

| 350*175*7*11 | 50 | 900*300*16*28 | 243 | 350*350*12*19 | 135 | ||

| 350*350*12*19 | 137 | ||||||

Production Flow Chart

Project Case

Pack And Ship

Certificate

Customer Praise

Plant And Equipment

FAQ

1. How can I get a quotation from you ?

You can leave us message, and we will reply every message in time. Or we may talk on line by Trademanager.And you can also find our contact information on contact page.

2.Can I get samples before order ?

Yes, of course. Usually our samples are free. we can produce by your samples or technical drawings. We can build the molds and fixtures.

3. what is your delivery time ?

The time of delivery is usually around 1 week(1*40FT as usual).We can send out in 2 days, if it has stock.

4.What is your payment terms?

Our usual payment term is 30% deposite, and rest against B/L. L/C is also acceptatble.EXW,FOB,CFR,CIF,DDU.

5. How can you garantee what I got will be good ?

We are factory with 100% predelivery inspection which garantee the quality.And as golden supplier on Alibaba. Alibaba assurance will make garantee,which means alibaba will pay your money back in advance if there is any problem with the products.

6 How do you make our business long-term and good relationship?

A: We keep good quality and competitive price to ensure our customers benefit ;

B. We respect every customer as our friend and we sincerely do business and make friends with them,no matter where they come from.Please feel free to leave us message if you have any question about us and our products.