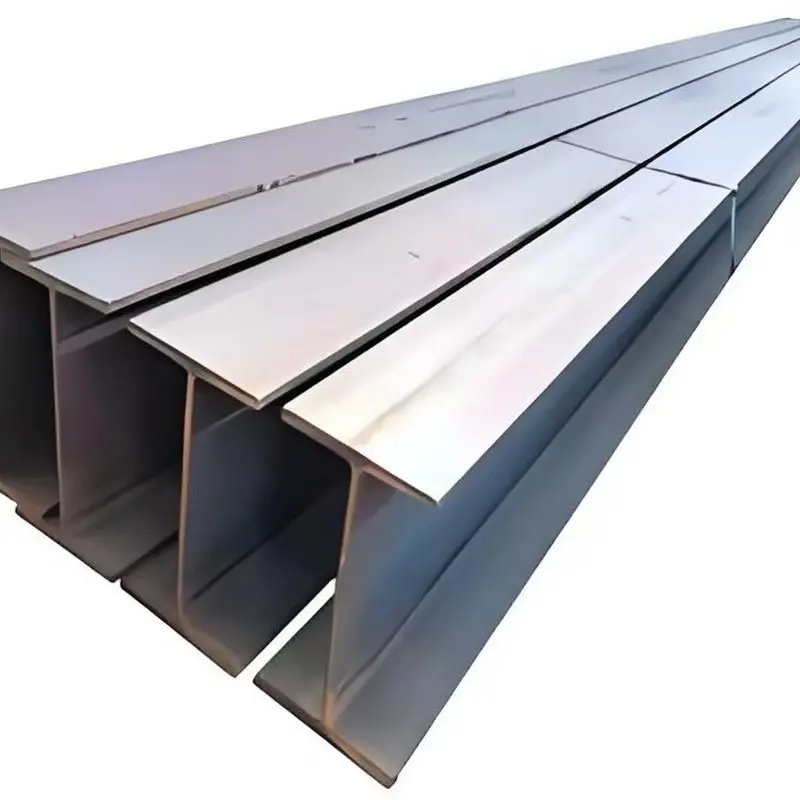

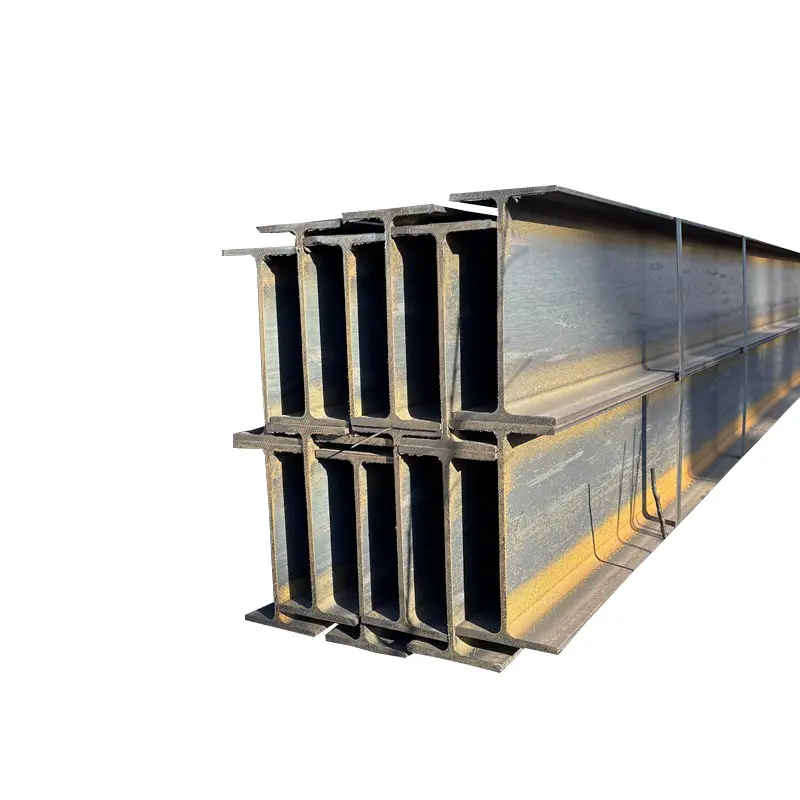

High Quality Q235 Q355 Structural Steel H Beam

As the name implies, I-beam is a kind of "I" shaped cross-section steel. The inner surface of the upper and lower flanges has an inclination of 1:6, which makes the flange thin outside and thick inside. As a result, the cross-sectional characteristics of the I-beam in the two main planes are very different, and it is difficult to exert the strength characteristics of the steel in the application, as shown in the first picture. Although thickened I-beams have appeared in the I-beam market, the structure of the I-beam has determined its torsional performance shortcomings.

Introduction to H-beam:

H-beam is a widely used profile in today's steel structure buildings. It has many differences compared with I-beam.

1) Flange, the inner surface of the flange has no inclination, and the upper and lower surfaces are parallel.

2) The inner sides of the two outer edges of the H-beam have no inclination and are straight.

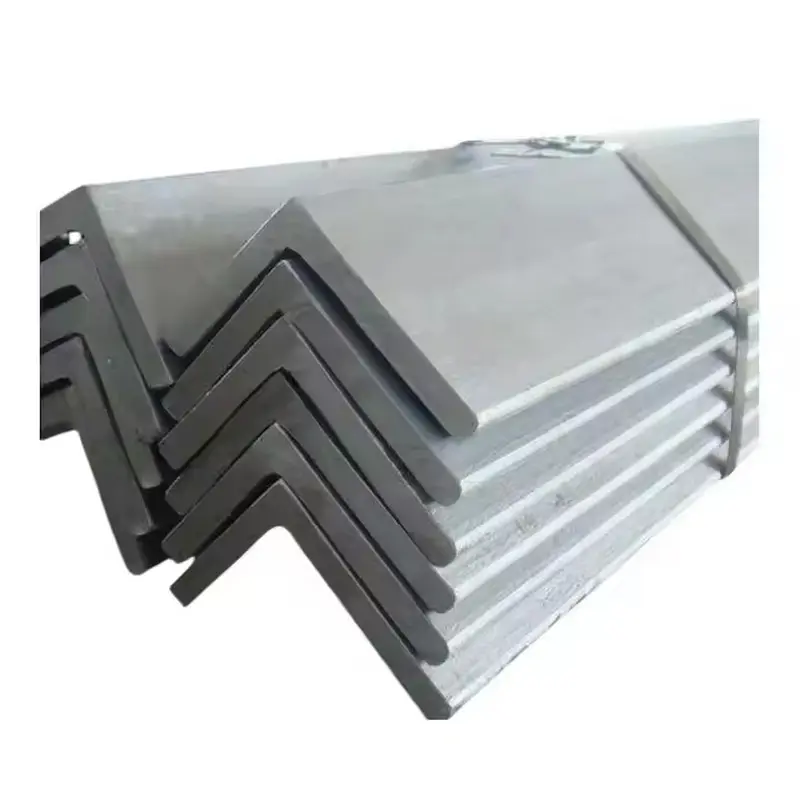

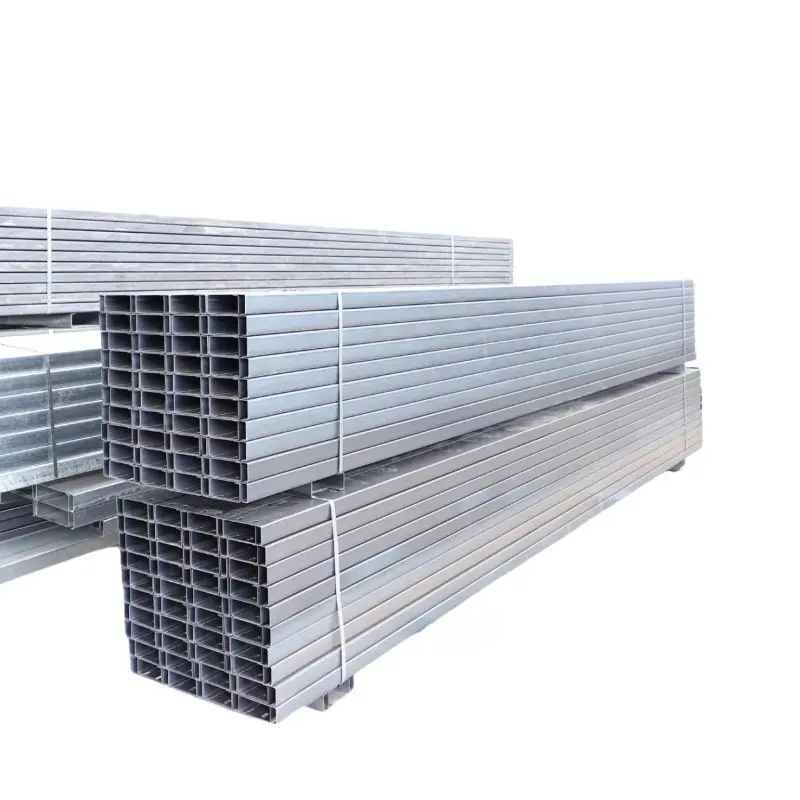

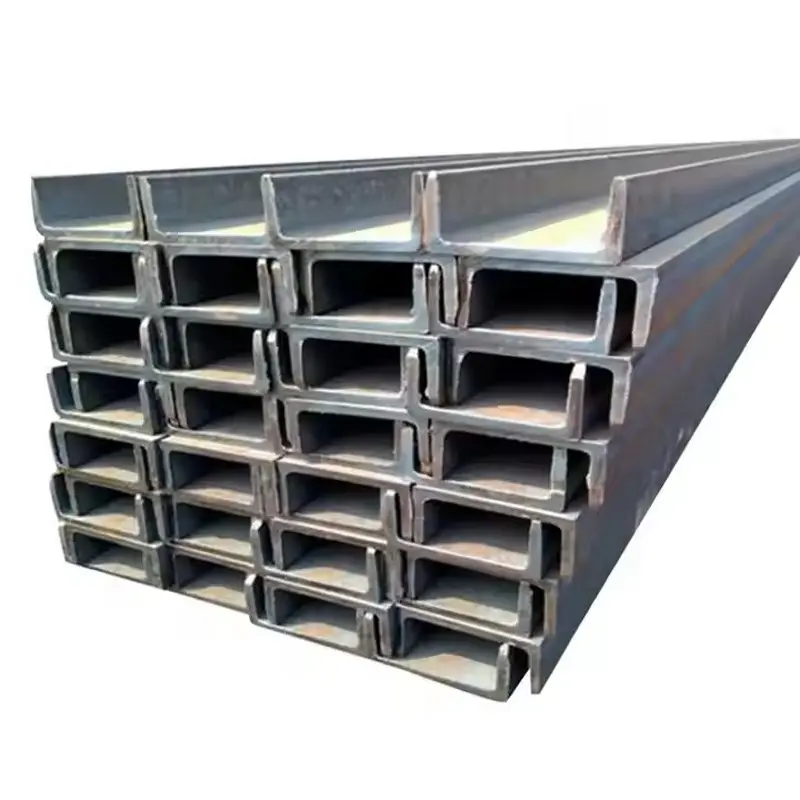

3) The cross-sectional characteristics of the H-beam are significantly better than traditional I-beams, channel steels and angle steels.

4) H-shaped steel is an economical and efficient profile with a more optimized cross-sectional area distribution and a more reasonable strength-to-weight ratio. It is named because its cross-section is the same as the English letter "H". This makes the welding and splicing of H-shaped steel simpler than that of I-shaped steel, and has better mechanical properties per unit weight, which can save a lot of materials and construction time.

Summary: The cross-section of I-shaped steel is good at bearing direct pressure and is resistant to tension, but the cross-sectional size cannot resist torsion because the flange is too narrow. H-shaped steel is the opposite, so both have their own advantages and disadvantages.

H-shaped steel is named because its cross-sectional shape is the same as the English letter "H". The flange of hot-rolled H-shaped steel is wider than that of I-shaped steel, has greater lateral stiffness and stronger bending resistance. Under the same specifications, the theoretical weight of H-shaped steel is lighter than that of I-shaped steel, which is more economical.

H-shaped steel has two process methods: hot rolling and welding. I-shaped steel is only rolled.

I-beams, whether ordinary or light, have relatively high and narrow cross-sectional dimensions, so the moment of inertia of the two main sleeves of the cross section differs greatly, which greatly limits its application range.

The flange of the H-shaped steel is widened, the lateral stiffness is large, and its stiffness around the weak axis is significantly increased, which can be used more reasonably for compressive members. The narrow flange series is also 1.1~1.4 times wider than the flange of the same height I-beam. Therefore, under the same cross-sectional area, the weak axis stiffness is 1 or more times larger; the bending resistance is strong.

Product Parameters

| GB H beam | JIS H beam | ||||||

| SIZE(mm) | KG/m | SIZE(mm) | KG/m | S1ZE(mm) | KG/m | SIZE(mm) | KG/m |

| 100*100*6*8 | 17.2 | 390*300*10*16 | 107 | 100*100*6*8 | 16.9 | 388*402*15*15 | 140 |

| 125125*6.5*9 | 23.8 | 396*199*7*11 | 56.7 | 125*125*6.5*9 | 23.6 | 390*300*10*16 | 105 |

| 150*75*5*7 | 14.3 | 400*150*8*13 | 55.8 | 150*75*5*7 | 14 | 396*199*7*11 | 56.1 |

| 148*100*6*9 | 21.4 | 400*200*8*13 | 66 | 148*100*6*9 | 20.7 | 400*200*8*13 | 65.4 |

| 150*150*7*10 | 31.9 | 400*400*13*21 | 172 | 150*150*7*10 | 31.1 | 400*150*8*13 | 55.2 |

| 175*90*5*8 | 18.2 | 400*408*21*21 | 197 | 175*90*5*8 | 18 | 400*400*13*21 | 172 |

| 175*175*7.5*11 | 40.4 | 414*405*18*28 | 233 | 175*175*7.5*11 | 40.4 | 400*408*21*21 | 197 |

| 194*150*6*9 | 31.2 | 428*407*20*35 | 284 | 194*150*6*9 | 29.9 | 414*405*18*28 | 232 |

| 198*99*4.5*7 | 18.5 | 440*300*11*18 | 124 | 198*99*4.5*7 | 178 | 428*407*20*35 | 283 |

| 200*100*5.5*8 | 21.7 | 446*199*8*12 | 65.5 | 200*100*5.5*8 | 20.9 | 440*300*11*18 | 121 |

| 200*200*8*12 | 50.5 | 450*200*9*14 | 76.5 | 200*200*8*12 | 49.9 | 446*199*8*12 | 65.1 |

| 200*204*12*12 | 56.7 | 482*300*11*15 | 115 | 200*204*12*12 | 56.2 | 450*200*9*14 | 74.9 |

| 244*175*7*11 | 44.1 | 488*300*11*18 | 129 | 244*175*7*11 | 43.6 | 482*300*11*15 | 111 |

| 248*124*5*8 | 25.8 | 496*199*9*14 | 79.5 | 248*124*5*8 | 25.1 | 488*300*11*18 | 125 |

| 250*125*6*9 | 29.7 | 500*200*10*16 | 89.6 | 250*125*6*9 | 29 | 496*199*9*14 | 77.9 |

| 250*250*9*14 | 72.4 | 506*201*11*19 | 103 | 250*250*9*14 | 718 | 500*200*10*16 | 88.2 |

| 250*255*14*14 | 82.2 | 582*300*12*17 | 137 | 250*255*14*14 | 81.6 | 506*201*11*19 | 102 |

| 294*200*8*12 | 57.3 | 588*300*12*20 | 151 | 294*200*8*12 | 55.8 | 582*300*12*17 | 133 |

| 294*302*12*12 | 85 | 594*302*14*23 | 175 | 294*302*12*12 | 83.4 | 588*300*12*20 | 147 |

| 298*149*5.5*8 | 32.6 | 596*199*10*15 | 95.1 | 298*149*5.5*8 | 32 | 594*302*14*23 | 170 |

| 298*201*9*14 | 65.4 | 600*200*11*17 | 106 | 300*150*6.5*9 | 36.7 | 596*199*10*15 | 925 |

| 300*150*6.5*9 | 37.3 | 606*201*12*20 | 120 | 300*300*10*15 | 93 | 600*200*11*17 | 103 |

| 300*300*10*15 | 94.5 | 692*300*13*20 | 166 | 300*305*15*15 | 105 | 606*201*12*20 | 118 |

| 300*305*15*15 | 106 | 700“300*13-24 | 185 | 340*250*9*14 | 78.1 | 692*300*13*20 | 163 |

| 340*250*9*14 | 79.7 | 792*300*14*22 | 191 | 346*174*6*9 | 41.2 | 700*300*13*24 | 182 |

| 346*174*6*9 | 41.8 | 800*300*14*26 | 210 | 350*175*7*11 | 49.4 | 800*300*14*26 | 207 |

| 350*175*7*11 | 50 | 900*300*16*28 | 243 | 350*350*12*19 | 135 | ||

| 350*350*12*19 | 137 | ||||||