Analysis of the performance characteristics, production process and application fields of carbon steel pipes

Analysis of the performance characteristics, production process and application fields of carbon steel pipes

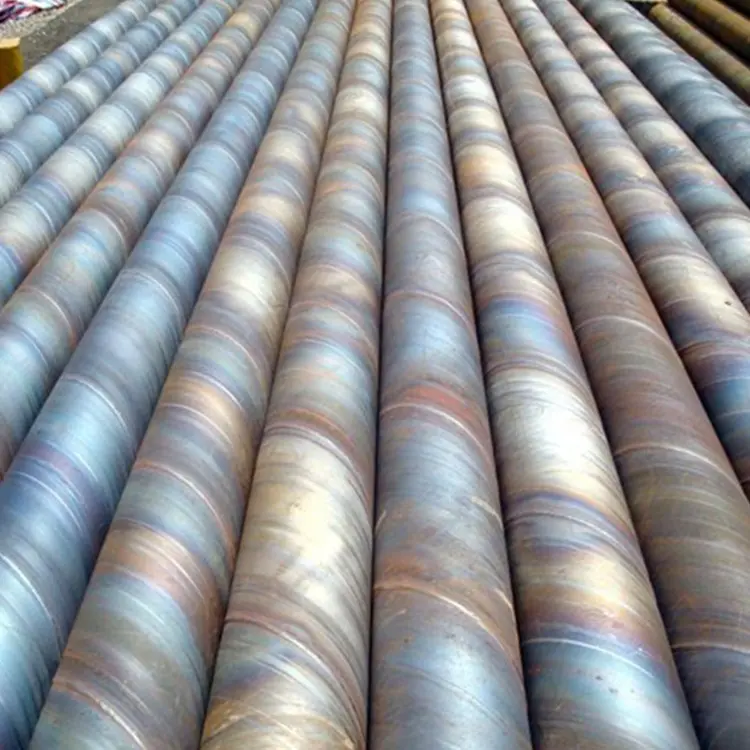

As an important industrial material, carbon Steel Pipes are widely used in the oil, natural gas, chemical and other industries due to their excellent mechanical properties and corrosion resistance. This article will explain the material characteristics, production process, main application fields and market status from four aspects.

1. Material characteristics of carbon steel pipes

Carbon steel pipes are mainly composed of carbon and iron, and have the following performance characteristics:

Excellent mechanical properties: Carbon steel pipes have high strength, good toughness, strong impact resistance, and are suitable for extreme working conditions such as high temperature and high pressure.

Good corrosion resistance: Through surface anti-corrosion treatment, it can resist the erosion of most corrosive media.

Low cost: Compared with other alloy steel pipes, the production cost of carbon steel pipes is more economical.

Convenient processing: It is easy to process into pipes and components of different shapes and sizes through cutting, welding, bending and other processes.

2. Production process of carbon steel pipes

The production process of carbon steel pipes mainly includes the following links:

Raw material preparation:Select high-quality carbon Steel Plates or billets as raw materials.

Heating treatment: Heat the raw materials to a suitable processing temperature.

Processing and forming: Raw materials are processed into pipes through rolling, extrusion, drawing and other processes.

Heat treatment: Heat treatment is performed on the formed pipes to improve their mechanical properties and corrosion resistance.

Surface treatment: Anti-corrosion coating or plating is performed to enhance the corrosion resistance of the pipes.

Testing and packaging: Strict quality inspection is performed on the finished products, and they are packaged and shipped after passing the inspection.

3. Main application areas of carbon steel pipes

Carbon steel pipes are widely used in the following industries:

Petroleum industry: used for oil well pipes, oil and gas pipelines, etc.

Natural gas industry: used for natural gas pipelines, gas storage tanks, etc.

Chemical industry: used for liquid pipelines and storage tanks in chemical processes.

Construction industry: used for building structure support, boilers and heating pipelines, etc.

Automobile manufacturing: used for automobile chassis pipes, exhaust pipes and other components.

4. Market status of carbon steel pipes

At present, the market demand for carbon steel pipes is strong, and the market scale continues to expand. There are many domestic carbon steel pipe manufacturers, distributors and suppliers, and the industry competition is fierce. Take Foshan Jingjin Steel Co., Ltd. as an example. The company focuses on the production and sales of carbon steel pipes and occupies a place in the market with rich experience and high-quality products.

The price, weight, size and specifications of carbon steel pipes have professional calculation standards to meet the diverse needs of different customers. In the face of market competition, manufacturers need to continuously improve product quality and technical level to adapt to the ever-changing market demand.

Conclusion

Carbon steel pipes play an important role in the industrial field with their excellent performance and wide application. In the future, with the advancement of technology and the upgrading of market demand, the carbon steel pipe industry needs to further develop new products to better adapt to the development needs of the industry.