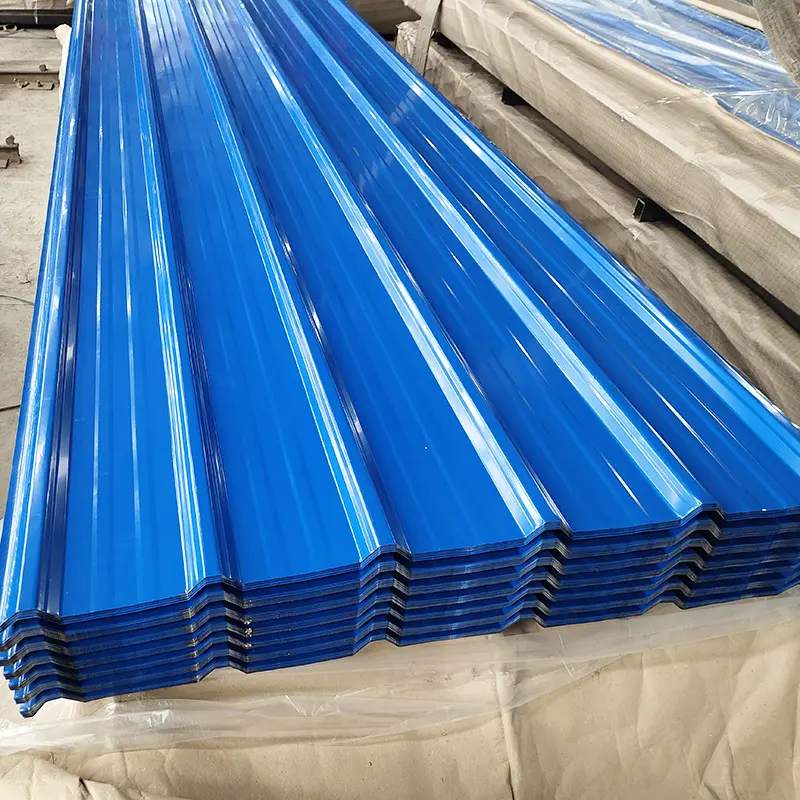

Color-coated corrugated board: the optimal solution for modern building envelope systems

In the field of modern industrial and civil construction, color-coated corrugated sheets (also known as color-coated corrugated sheets, corrugated Steel Sheets) have become one of the preferred materials for roof and wall enclosure systems due to their significant advantages such as light weight, high strength, rich colors, convenient construction, economical and durable. Its diverse models, excellent material properties and wide range of application scenarios continue to promote the progress and development of the construction industry.

Core advantages: light weight, high strength, beautiful and durable

The core of color-coated corrugated sheets lies in their unique structural design and surface treatment process:

Substrate material: High-quality hot-dip galvanized steel sheets, aluminum-zinc-coated steel sheets (such as AZ150, AZ180) or higher-end aluminum-magnesium-zinc-coated steel sheets are usually used as substrates. These substrates provide excellent anti-corrosion ability and are the fundamental guarantee for the long-term service life of the sheets.

Surface coating: After strict chemical pretreatment, the substrate is coated with high-performance polyester (PE), silicon-modified polyester (SMP), high weather-resistant polyester (HDP) or polyvinylidene fluoride (PVDF) and other coatings. These coatings not only give the board a colorful appearance (customizable according to RAL, Pantone and other color cards), but more importantly, they provide excellent weather resistance, UV resistance, chemical corrosion resistance and scratch resistance, ensuring that the building appearance is long-lasting and new.

Corrugated structure: Through a precise roll-forming process, the flat plate is processed into various corrugated (corrugated) structures. This structure greatly improves the rigidity and load-bearing capacity of the board, so that it can maintain good stability under a large span, and has a good drainage and diversion effect.

Diverse models to meet different needs

Color-coated corrugated boards have a rich model series to adapt to different building functions, load requirements and aesthetic designs:

Common tile types (model examples):

V-820 / V-840: Classic hidden connection tile type, the overlap is fixed by a bracket, there are no exposed screws on the surface, the appearance is neat and atmospheric, and the waterproof performance is excellent. It is often used in high-standard Factory buildings and public building roofs.

YX25-205-820 / YX28-205-820: Wave height 25mm/28mm, wave distance 205mm, effective coverage width 820mm. Good structural strength, high cost performance, and extremely wide application.

YX35-125-750: Wave height 35mm, wave distance 125mm, effective coverage width 750mm. High wave crest, strong bearing capacity, suitable for roofs in areas with high load-bearing or snow load requirements.

YX15-225-900: Wave height 15mm, wave distance 225mm, effective coverage width 900mm. Low wave height, flat plate shape, often used for walls, and also suitable for roofs with smaller slopes.

Other models: Such as YX51-380-760 (ultra-high wave crest, large span), YX76-344-688 (trapezoidal wave, special purpose), various antique tile types, etc. The specific model naming rules may vary from manufacturer to manufacturer, but usually include key parameter information such as wave height, wave distance, effective width, etc.

Selection basis: The choice of model mainly depends on the purpose of the building (load requirements), span, slope, waterproof requirements, wind pressure/snow pressure area and building appearance design preferences.

Wide range of applications

The application range of color-coated corrugated board is extremely wide, covering almost all enclosure structure scenarios that require lightweight, fast construction, economical and durable:

Industrial buildings:

Factories and warehouses: The roofs and walls of large production workshops and logistics storage centers are its main application areas. Its fast installation characteristics greatly shorten the construction period.

Equipment room/auxiliary room: boiler room, power distribution room, pump room, etc.

Commercial and public buildings:

Large shopping malls/supermarkets: Part of the roof and wall system.

Stadiums: Grandstand roofs, auxiliary facilities buildings.

Exhibition halls/trading markets: Roofs of large-span exhibition halls.

Stations/airports: ancillary facilities, canopies, partial roofs.

Logistics and agricultural facilities:

Logistics centers/distribution stations: main warehouse structures.

Agricultural product markets/greenhouses: partially covered structures.

Poultry and livestock farms: roofs and enclosures of modern farms.

Other areas:

Temporary buildings/mobile board houses: temporary facilities that can be quickly erected.

Renovation of old buildings: flat to sloped, exterior wall renovation.

Partitions/enclosures: construction site enclosures, internal partitions of the park.

Interior decoration: indoor ceiling or wall decoration with industrial style (specific models and surface treatments are required).

Promote green and efficient buildings

The production and use of color-coated corrugated boards are in line with the pursuit of efficiency, economy and environmental protection in modern buildings:

Fast construction: greatly shorten the construction period and reduce labor costs.

Easy maintenance: good surface self-cleaning properties and low daily maintenance costs.

Recyclable: The steel substrate is 100% recyclable, which is in line with the concept of sustainable development.

Energy-saving potential: It can be combined with thermal insulation materials (such as color steel sandwich panels) to significantly improve the thermal insulation performance of buildings and reduce energy consumption.