Color-Coated Steel Coil: A Versatile Material Revolutionizing Modern Construction and Manufacturing

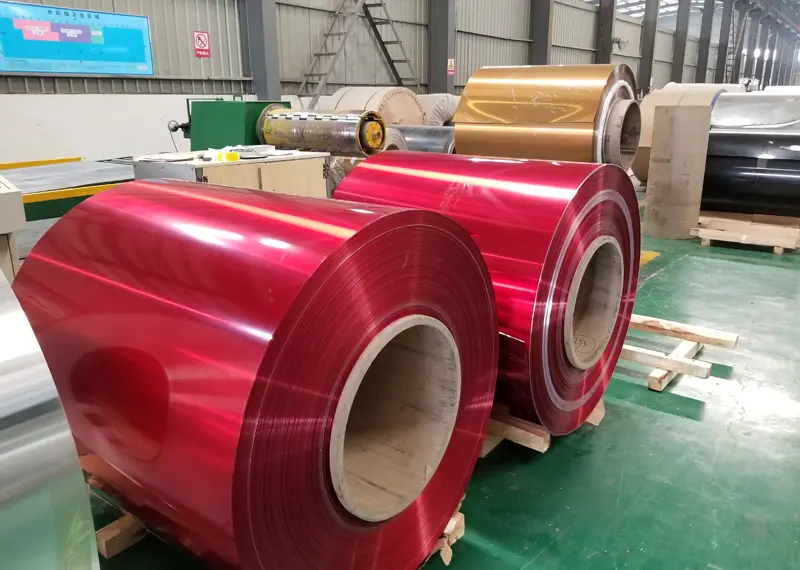

Color-coated steel coils, a high-performance material widely used in modern construction and manufacturing, are gaining prominence due to their excellent mechanical properties, aesthetic appeal

corrosion resistance,fire retardancy, and additional functional features. These coils are manufactured by processing and coating Steel Plates, with base materials including cold-rolled steel, hot-dip galvanized steel, electro-galvanized steel, and more.

Applications of Color-Coated Steel Coils

Color-coated Steel Coils are extensively utilized across various industries:

-

Construction: Roofing, roofing structures, rolling shutters, kiosks, louvers, security gates, bus shelters, and ventilation ducts.

-

Home Appliances & Furniture: Refrigerators, air conditioners, electric stoves, washing machine casings, and petroleum heaters.

-

Transportation: Automotive ceilings, back panels, partitions, vehicle shells, tractors, and ship bulkheads.

Among these applications, steel-structured factories, composite panel workshops, and color steel tile factories remain the most common uses.

Market Trends and Technological Advancements

The development of color-coated steel coils is not simply categorized as "good" or "bad"—it depends on market demand and manufacturers' positioning. Adapting to market needs is the key factor for success.

High-end technologies such as aluminum-zinc (Al-Zn) and magnesium-aluminum (Mg-Al) coatings are increasingly used in automotive and home appliance industries due to their superior performance.

Meanwhile, color-coated coils are widely adopted in:

-

Large-span factories, warehouses, offices, villas

-

Roof extensions, cleanrooms, cold storage units

-

Retail kiosks and temporary structures

Production Process & Coating Structures

Color-coated steel coils are produced through a continuous process where cold-rolled, galvanized (electro or hot-dip), or Al-Zn-coated steel undergoes surface treatment (degreasing and chemical processing),

followed by liquid coating application via rollers. After baking and cooling, the final coated sheet is obtained.

In China, typical coatings include:

-

One-layer primer (back) + two-layer topcoat (front)

Internationally, two-layer coatings on both sides are more common.

Due to its vibrant color options, coated steel is often referred to as color-coated steel, pre-painted steel coil, or color steel strip.

Classification of Color-Coated Steel Coils

Color-coated steel can be categorized in multiple ways:

-

By Surface Finish: Standard, printed, embossed, or laminated.

-

By Coating Structure: 2/1, 2/2, 2/1M, 3/2 (indicating front/back coating layers).

-

By Base Material: High-strength steel (e.g., TS550), forming steel (TDC51D, TDC52D), and structural steel (TS280GD, TS350).

-

By Gloss Level: High-gloss (≥70°), medium-gloss (40°-70°), low-gloss (≤40°).

-

By Paint Type: Polyester (PE), high-durability polyester (HDP), silicon-modified polyester (SMP), PVDF.

-

By Application: Exterior/interior construction, steel windows, furniture, appliances.

-

By Functional Properties: Anti-static, self-cleaning, heat-insulating, antibacterial, scratch-resistant.

Base Material (Coating Layer) Comparison

The quality of color-coated steel largely depends on the base material and coating process:

-

Cold-Rolled Steel: Lacks corrosion resistance, prone to rust.

-

Electro-Galvanized Steel: Thin zinc layer, moderate corrosion resistance; used in appliances and indoor applications.

-

Hot-Dip Galvanized Steel: Offers strong adhesion, thicker zinc layer (Z50–Z275g/m²), and excellent durability for outdoor construction and machinery.

-

Hot-Dip Al-Zn Coated Steel (55% Al, 43.5% Zn, 1.5% Si): Superior corrosion resistance (twice that of galvanized steel), available in AZ30–AZ150g/m² coatings.

Conclusion

As industries demand more durable, aesthetically pleasing, and functional materials, color-coated steel coils continue to evolve, meeting diverse market needs.

With advancements in coating technologies and expanding applications, this material is set to play an even greater role in construction, manufacturing, and beyond.

Email:manager@fsdsteel.com

Phone/Whatsapp:+86-18831507725