Do you know about steel sheet piles?

The reputation of steel sheet piles in the engineering world is almost comparable to that of reinforced concrete.

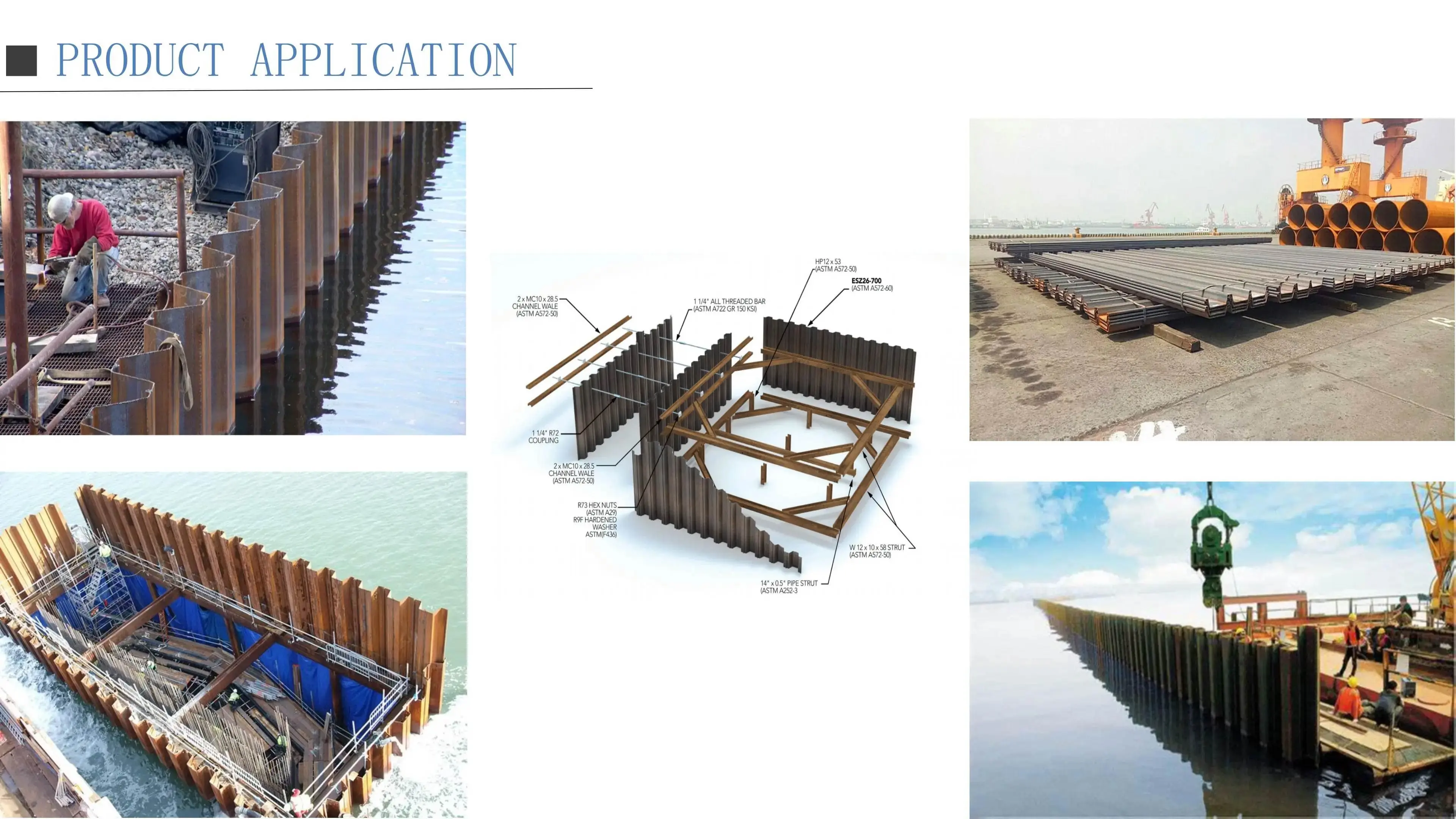

When it comes to small foundation pit support excavation, especially municipal engineering, steel sheet piles are the most common and relatively cost-effective support method.

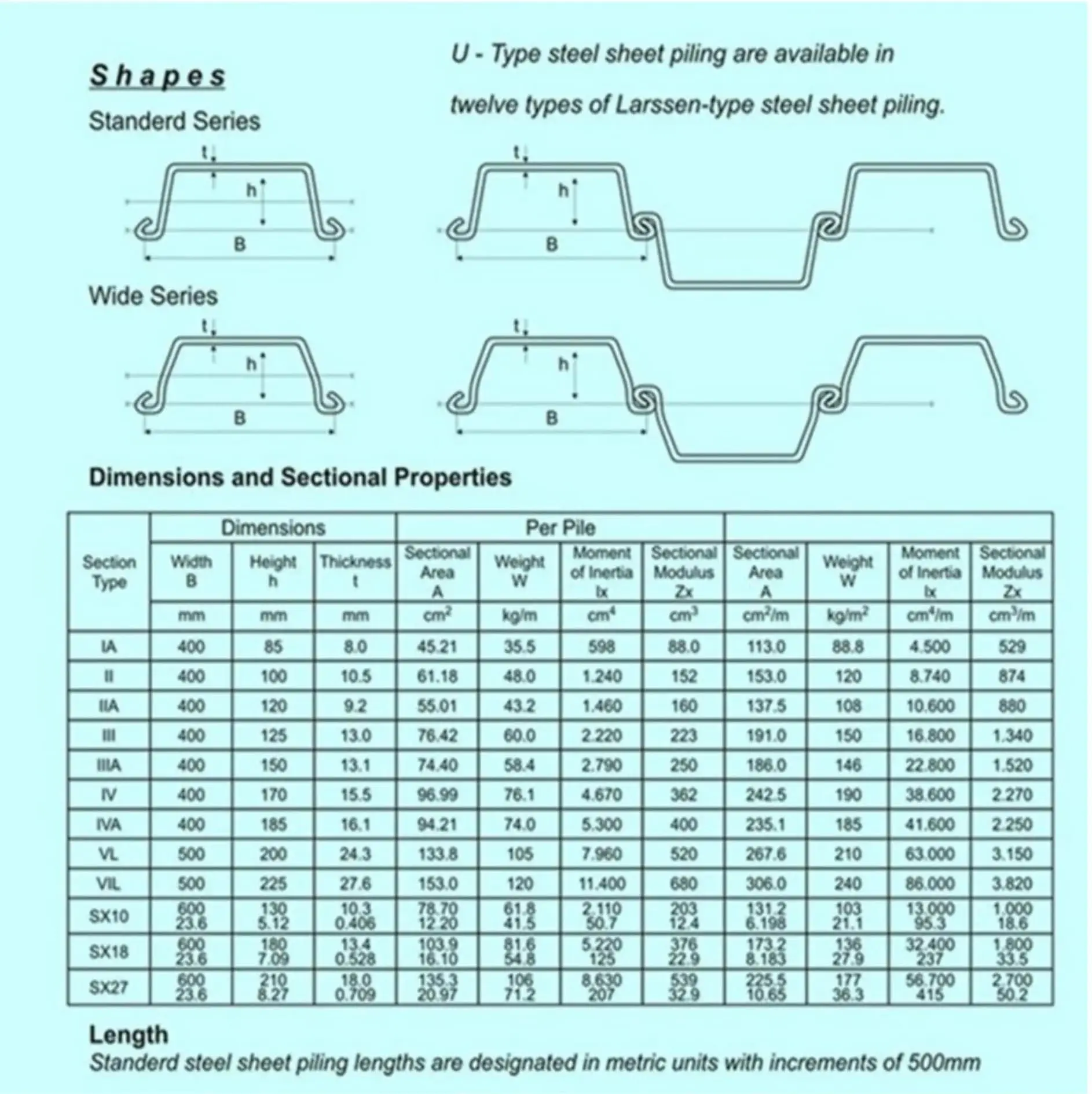

Steel sheet piles are a type of Steel with a lock, and the cross-sections are straight, Z-shaped, U-shaped, H-shaped, cap-shaped, etc.

Steel sheet pilesare divided into two types according to the production process: cold-bent Steel Sheet piles and hot-rolled steel sheet piles, and the latter is dominant.

There are also many different sizes and lock forms, such as the most commonly mentioned Larsen steel sheet piles.

Why is it called Larsen? Because the engineer who invented this steel sheet pile is called Larssen. The so-called Larsen is a U-shaped steel sheet pile with interlocking rivets.

To put it simply, it is a steel sheet pile with a U-shaped protruding cross-section that can be used to interlock adjacent steel sheet piles.

The steel sheet pile support structure is to drive the steel sheet piles into the soil layer and set up necessary supports or anchors to resist soil pressure and water pressure and maintain the stability of the surrounding strata.

Steel sheet pilesare Factory finished products with many advantages such as convenient construction, short construction period and low cost.

However, during the construction process, attention should be paid to the waterproofing of the joints to prevent the collapse and instability of the stratum caused by soil erosion at the joints (personal experience, deep foundation pits with poor geology and abundant groundwater are generally equipped with water-stop curtains on the outer circle, such as jet grouting piles, and pit reinforcement is set inside).

In addition, the rigidity of steel sheet piles is smaller than that of pile rows and ground-connected walls, and the deflection deformation is larger after excavation.

Therefore, the general design will require a load limit within 2m around the foundation pit, and the construction should pay attention to fast excavation and fast filling.

Excavation and support construction is a key process that determines the success or failure of foundation pit projects.

The general order of steel sheet pile support is:

find out the underground obstacles-->level the site and determine the pile position-->press the steel sheet pile-->construct drainage measures-->excavate and set up support (or anchor)-->excavate to the bottom of the foundation pit and do foundation treatment in time (if any, or treat in advance)-->construct the cushion layer and main structure and backfill in time-->backfill to the ground level-->recover the steel sheet pile-->continue to backfill to the designed ground.

As a temporary support structure for construction, or as a support structure as part of a permanent structure, the foundation pit itself is required to have a certain stability to prevent the foundation pit from stability damage (overall, kicking, uplift, pipe burst, quicksand) and strength damage (buckling, slip, wall damage).