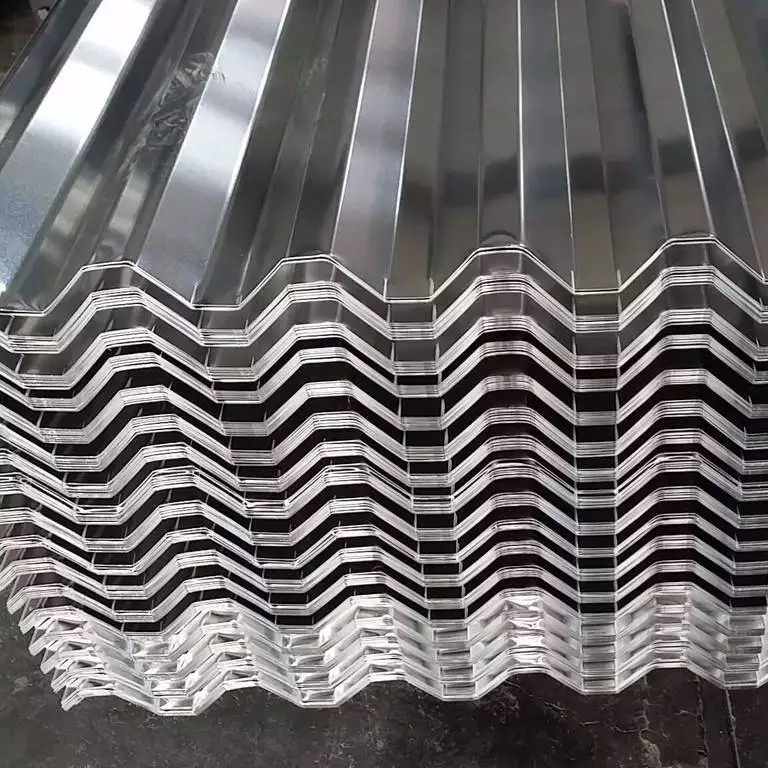

Galvanized Corrugated Sheet – Models, Materials, Uses, and Applications

Galvanized corrugated sheets are widely used in construction and industrial applications due to their durability, weather resistance, and cost-effectiveness. This article provides an overview of their common models, materials, uses, and applications.

1. Common Models

Galvanized corrugated sheets are available in various models, categorized by wave height and pitch:

-

V25 (25mm wave height) – Suitable for roofing and cladding.

-

V32 (32mm wave height) – Offers higher strength for industrial buildings.

-

V40 (40mm wave height) – Used in heavy-duty applications requiring enhanced load-bearing capacity.

-

Custom wave designs – Some manufacturers provide tailored patterns for specific structural needs.

2. Material Composition

-

Base Material: High-quality Steel (DX51D, DX52D, or equivalent grades).

-

Coating: Hot-dip galvanized (Zinc coating: 60-275 g/m²) for corrosion resistance.

-

Optional Coatings: Some sheets feature additional anti-rust treatments or color coatings (e.g., PVDF or polyester) for aesthetics and extended durability.

3. Key Uses

-

Roofing: Ideal for industrial, agricultural, and residential roofs.

-

Wall Cladding: Provides structural support and weather protection.

-

Temporary Shelters: Used in disaster relief and construction sites.

-

Fencing & Partitions: Offers a sturdy, long-lasting barrier solution.

4. Applications Across Industries

-

Construction: Widely adopted in warehouses, factories, and farm buildings.

-

Transportation: Used for truck trailers and container modifications.

-

Infrastructure: Applied in drainage covers and highway sound barriers.

-

Renewable Energy: Serves as a base for solar panel installations.

Conclusion

Galvanized corrugated sheets are versatile, economical, and resilient, making them essential in modern construction and industrial projects. With multiple models and material options, they cater to diverse structural and protective needs worldwide.