0102030405

Galvanizing Process: The Key Technology for Industrial Rust Prevention and the Driver of Development in Various Industries

2025-01-20

In the grand stage of industrial production, rust prevention has always been a crucial topic to ensure product quality and service life. The galvanizing process, as an efficient and widely used anti - rust method, is playing an indispensable role. Recently, the reporter visited several enterprises in the industry to gain an in - depth understanding of the story behind the galvanizing process.

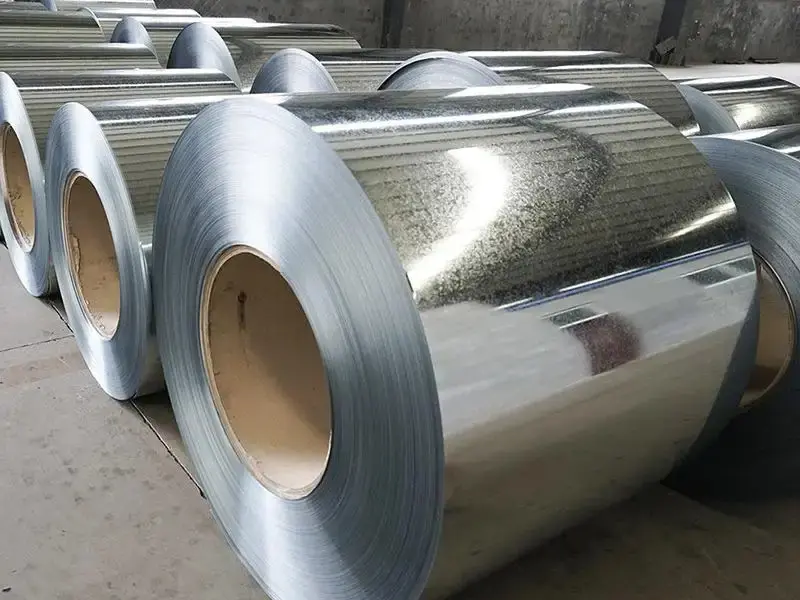

The galvanizing process, simply put, is to coat a layer of zinc on the metal surface to protect the metal from corrosion. This seemingly simple operation, however, contains many complex technical details. Currently, hot - dip galvanizing and electro - galvanizing are the two most common galvanizing processes.

Electro - galvanizing, on the other hand, uses the principle of electrolysis to deposit a layer of zinc on the metal surface. This process can precisely control the thickness of the zinc layer, and the formed zinc layer is uniform, fine, and has a high surface quality. Therefore, electro - galvanizing is highly favored in industries with high requirements for appearance and precision, such as automotive parts manufacturing and household appliance shell production. Components such as car door handles and rear - view mirror brackets, after being treated by electro - galvanizing, not only have excellent anti - rust capabilities but also maintain a bright appearance, enhancing the overall texture and market competitiveness of the products.

Whether it is hot - dip galvanizing or electro - galvanizing, the pre - treatment work in the early stage is of vital importance. Before galvanizing, metal workpieces must go through strict steps such as cleaning, degreasing, and pickling to remove impurities such as oil stains, rust, and oxide scale on the surface. Only in this way can the good adhesion between the zinc layer and the metal surface be ensured.

With the continuous progress of science and technology, the galvanizing process is also constantly innovating. New galvanizing additives are emerging in an endless stream, which can further improve the quality and performance of the zinc layer; automated galvanizing production lines are gradually becoming popular, which not only improves production efficiency but also reduces errors caused by manual operations, making the quality of galvanized products more stable and reliable.

As the main force in industrial rust prevention, the galvanizing process plays an important role in various industries. From large - scale buildings to small electronic products, it silently protects metal products, extends their service life, and improves their performance. It is believed that in the future, with the further development of technology, the galvanizing process will continue to break through and innovate, injecting new vitality into the development of the industrial field and promoting various industries to a higher level.

Contact Us for More Information

Email:manager@fsdsteel.com

Phone/Whatsapp:+86-19133613100