H-beam: New economical construction steel leads the industry change

H-beamis a new type of economic building Steel.H-shaped steel has an economical and reasonable cross-sectional shape, good mechanical properties, and uniform extension at various points on the cross-section during rolling, with low internal stress. Compared with ordinary I-Beams, it has the advantages of large cross-sectional modulus, light weight, and metal saving, which can reduce the weight of building structures by 30-40%;

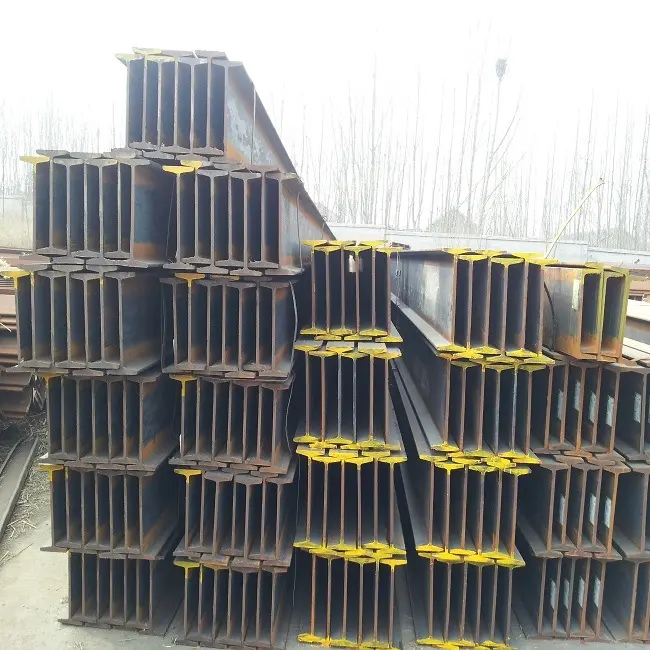

Due to the parallel inner and outer sides of its legs and the right angle of its leg ends, it can be assembled into a component, saving up to 25% of welding and riveting work. Commonly used for large buildings that require high load-bearing capacity and good cross-sectional stability (such as factories, high-rise buildings, etc.), as well as bridges, ships, lifting and transportation machinery, equipment foundations, brackets, foundation piles, etc. H-section steel is an economical section steel with superior mechanical properties, developed through the optimization of I-section steel, especially named after its section being identical to the English letter "H".

H-beam is a new type of economic building steel. H-shaped steel has an economical and reasonable cross-sectional shape, good mechanical properties, and uniform extension at various points on the cross-section during rolling, with low internal stress. Compared with ordinary I-beams, it has the advantages of large cross-sectional modulus, light weight, and metal saving, which can reduce the weight of building structures by 30-40%; Due to the parallel inner and outer sides of its legs and the right angle of its leg ends, it can be assembled into a component, saving up to 25% of welding and riveting work. Commonly used for large buildings that require high load-bearing capacity and good cross-sectional stability (such as factories, high-rise buildings, etc.), as well as bridges, ships, lifting and transportation machinery, equipment foundations, brackets, foundation piles, etc. H-beams are mainly used in industrial plants, civil buildings, municipal engineering, oil platforms, bridges, flatbed truck beams, power supports for electrified railways, steel structure bridges along railways, and other light and ultra light H-beams. They are very suitable for container, mobile housing, various garages, box type trains, electrical supports, various venues, and small villa manufacturing industries. Hot rolled H-beams have excellent mechanical properties and superior usability by reasonably allocating the aspect ratio of cross-sectional dimensions according to different applications. High structural strength. Compared with I-beams, the section modulus is larger, which can save 10-15% of metal under the same bearing conditions. The design style is flexible and rich. Under the same Beam Height, the spacing ofsteel structures can be 50% larger than that of concrete structures, making the building layout more flexible. The structure has a light weight. Compared with the self weight of concrete structures, the reduction of structural self weight reduces the internal forces in structural design, which can lower the requirements for foundation treatment of building structures, simplify construction, and reduce costs.

The steel structure mainly made of hot-rolled H-beams has a scientifically reasonable structure, good plasticity and flexibility, high structural stability, and is suitable for building structures that can withstand large vibration and impact loads. It has strong resistance to natural disasters and can significantly save labor and materials compared to welded H-beams. It can reduce the consumption of raw materials, energy, and labor, has low residual stress, and has good appearance and surface quality. Easy to machine, connect and install, and also easy to dismantle and reuse. The use of H-beams can effectively protect the environment. Steel structures mainly made of hot-rolled H-beams have a high degree of industrial production, which is convenient for mechanical manufacturing, intensive production, high precision, easy installation, and easy quality assurance. They can be built into real factories for building construction, bridge construction, industrial plant construction, etc. The development of steel structures has created and driven the growth of hundreds of emerging industries. The construction speed is fast, the footprint is small, and it is suitable for all-weather construction with little influence from climate conditions.