High efficiency, environmental protection, stable and reliable - steel sheet piles

Steel sheet pilesare a type of Steel structure with linkage devices on the edges that can be freely combined to form a continuous and tight retaining wall or water retaining wall.

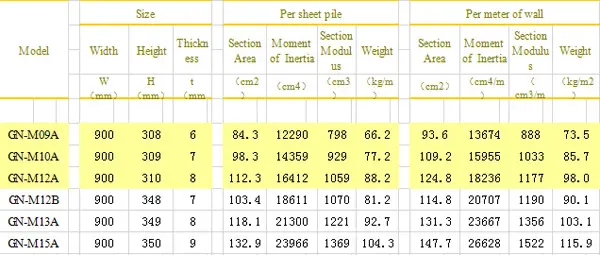

M-type steel sheet pileshave the world's largest effective width of a single Steel Sheet pile - 900mm. Compared with the existing sizes of 400mm and 600mm, the number of pile blocks, the number of locks, and the amount of water seepage can be greatly reduced on the same construction length, and the construction period and construction costs can be shortened.

[Features of Z-type steel sheet piles]

1. Economical

The Z-type steel sheet pile can build a continuous wall with a large cross-section shape through the lock design at both ends. Compared with the cross-section of general steel sheet piles such as U-type steel sheet piles, it is a lighter weight, higher cross-sectional performance, and more efficient product. It is for this reason that the cost of materials can be greatly reduced when the cross-sectional performance is the same.

2. Shorten the construction period

Z-type steel sheet piles with larger cross-sectional shapes can reduce the number of construction roots when the construction length is the same, thereby reducing the time for taking and piling steel sheet piles and shortening the construction period.

3. Water-stopping property

For Z-shaped steel sheet piles with a larger cross-sectional shape, the number of roots can be reduced when the length of the construction is the same, and the lock part that will cause a little leakage will also be greatly reduced, and the leakage amount will be effectively suppressed. In addition, the gap between the lock of GQNS-Z type and the existing cold-bent steel sheet pile is smaller, which can play a better water-stopping property.

4. Reliability of the structure

The lock position of the Z-shaped steel sheet pile is located outside the central axis, and it will not be affected by the longitudinal shear force generated near the central axis during bending deformation, and the lock will not be disengaged. It is a reliable product that will not reduce the interface performance due to disengagement.

Product features of steel sheet piles

High strength and durability

Steel sheet piles are made of high-quality steel and have extremely high bending and compression resistance. They can withstand complex soil pressure and water pressure and are suitable for deep foundation pit support, retaining walls, cofferdams and other engineering scenarios.

Convenient and efficient construction

Compared with traditional concrete support, steel sheet piles are installed quickly and can greatly shorten the construction period. Its modular design supports rapid insertion and removal, which is particularly suitable for emergency projects or temporary support needs.

Reusable and environmentally friendly

Steel sheet piles can be recycled multiple times to reduce the generation of construction waste, which is in line with the modern green construction concept. According to estimates, its recycling rate exceeds 90%, significantly reducing the carbon emissions of the project.

Strong adaptability

Whether it is soft soil foundation, sandy stratum or underwater construction, steel sheet piles can provide stable support effects. In addition, by combining different models (such as U-type, Z-type, and straight-line types), it can meet diverse engineering needs.

Wide range of applications

Municipal engineering: subway, undergRound Pipe gallery, bridge foundation support

Water conservancy engineering: river regulation, embankment reinforcement, port terminal construction

Industrial and civil construction: basement excavation, temporary enclosure

Transportation infrastructure: road and railway subgrade support