Hot-Rolled Steel Sheets: Versatile Applications and Market Trends

Hot-rolled steel sheets, produced by rolling Steel ingots or continuous casting slabs at high temperatures, remain a cornerstone material across diverse industries. With a typical thickness of 1.2mm or above, these sheets are celebrated for their exceptional plasticity, weldability, and cost-effectiveness, making them ideal for structural and welded components.

Production Process

The manufacturing of hot-rolled steel involves multiple stages: cutting (head, tail, and edges), straightening, leveling, and precision processing to produce final products such as hot-rolled steel plates, leveled coils, and slit strips. Further treatment, including acid washing to remove oxide layers and oil coating, yields hot-rolled pickled Steel Coils—a cost-efficient alternative to cold-rolled sheets that has gained significant market traction.

Key Applications of Hot-Rolled Steel

-

Structural Steel

Used in construction frameworks, bridges, ships, and vehicle manufacturing due to its durability and ease of shaping. -

Weathering Steel

Enhanced with elements like phosphorus (P) and copper (Cu), this variant offers superior corrosion resistance for containers, specialized vehicles, and architectural structures. -

Automotive Structural Steel

High-strength sheets with excellent stamping and welding properties, critical for producing chassis, wheels, and other automotive components. -

Specialized Hot-Rolled Steel

Carbon, alloy, and tool steels undergo heat treatment to manufacture precision machinery parts. -

Cold-Rolling Base Material

Serves as raw material for cold-rolled products, including CR (cold-rolled), GI (galvanized), and color-coated sheets. -

Steel Plate for Pressure Vessels

Engineered for high-pressure applications, such as LPG and gas containers (under 500L capacity), combining formability with robust strength. -

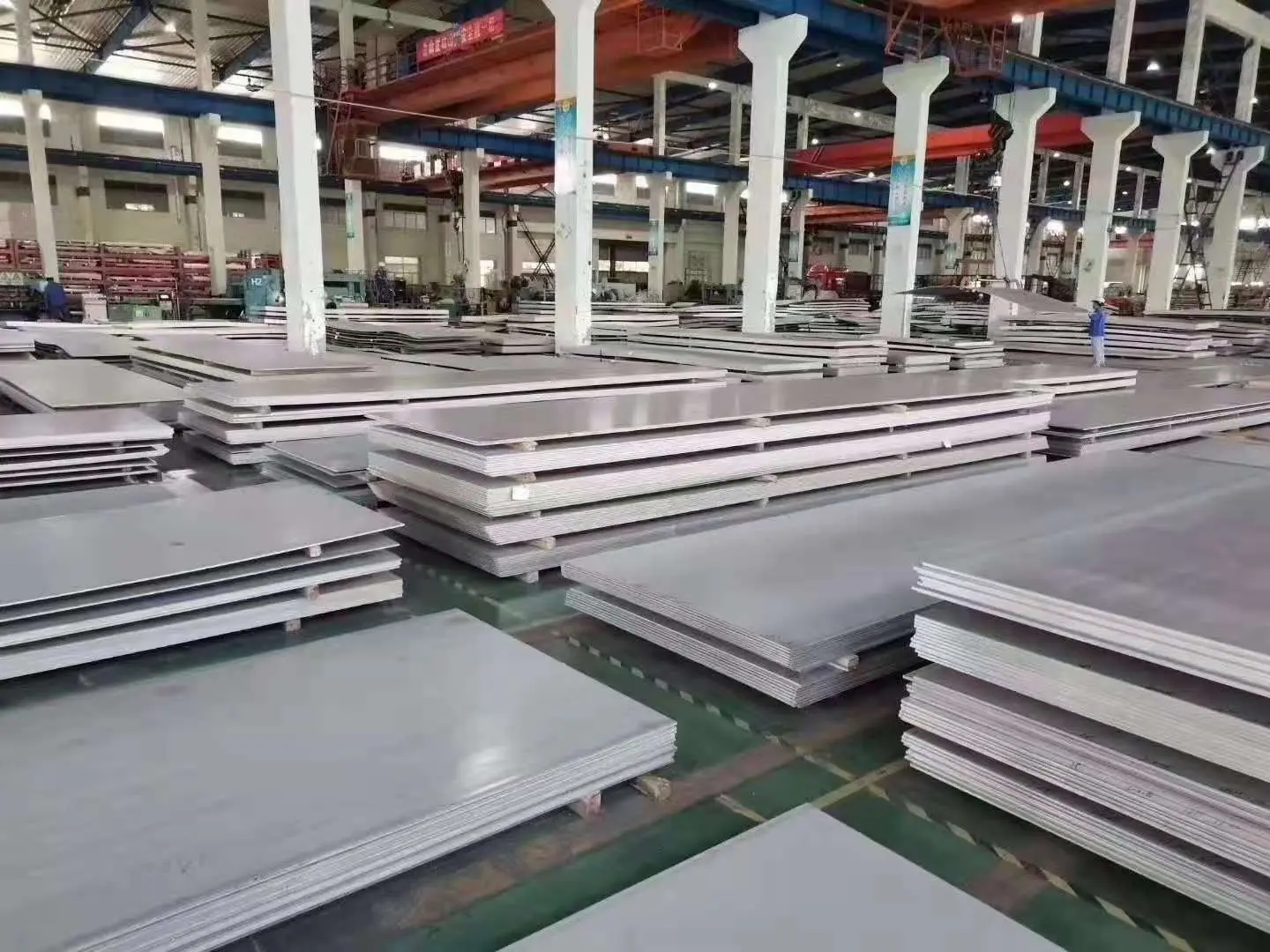

Stainless Steel Sheets

Corrosion-resistant solutions for the food, medical, aerospace, and chemical industries.

Hot-Rolled vs. Cold-Rolled Steel

-

Hot-rolled steel (thickness ≥2.0mm) boasts superior ductility and weldability but lower hardness. Its surface may show oxidation marks, limiting high-precision uses.

-

Cold-rolled steel (0.3–3.0mm) offers higher strength, hardness, and smoother surfaces, ideal for thin, precision parts. However, its reduced toughness and unpredictable failure modes under overload require cautious engineering.

Contect Us for More Information

Email:manager@fsdsteel.comPhone/Whatsapp:+86-18831507725