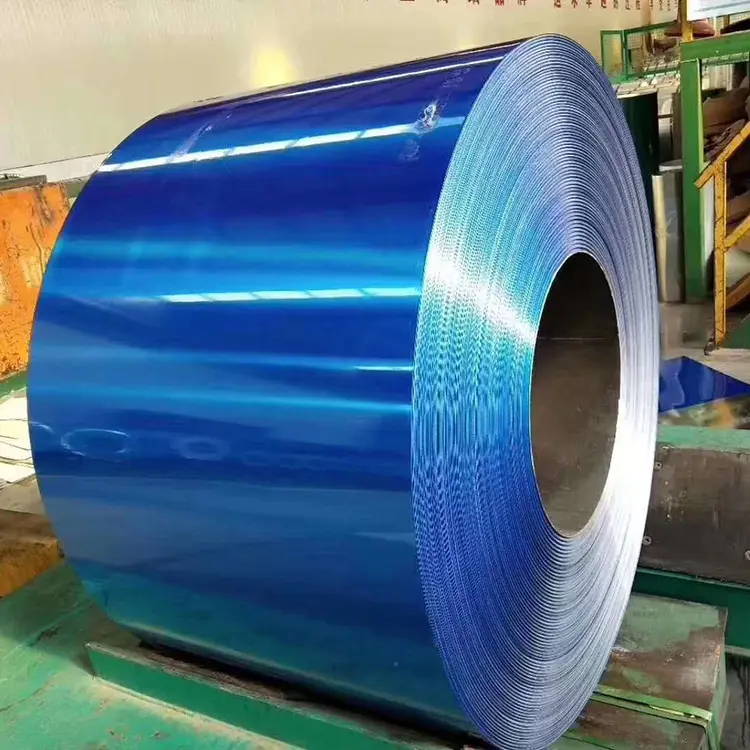

How Does the Galvanized Coil “Transform” into a Color – PPGI Coil?

Color-coated steel coils are widely used in many fields such as construction and home appliances due to their rich colors and excellent performance.

But do you know that its "predecessor" is galvanized steel coils? The following will reveal to you how galvanized Steel Coils are produced into color-coated steel coils.

The difference between galvanized steel coil and color-coated steel coil

Galvanized steel coil is a steel coil with a layer of zinc on its surface, which mainly plays a role in rust prevention and extends the service life of steel. Color-coated steel coil uses galvanized steel coil as the base material, and after processing, an organic coating is applied on its surface. This not only retains the rust prevention performance of galvanized steel coil, but also increases the beauty and weather resistance.

Key production steps

(1) Pretreatment process

Degreasing: Remove surface oil, dust and other impurities through alkaline solution or chemical degreasing agent to ensure better combination of subsequent coating and substrate.

Chemical conversion treatment: Use chromium or chromium-free passivation treatment to form a chemical film on the surface of the galvanized layer to enhance the adhesion between the substrate and the paint.

(2) Painting process

Primer coating: Primer is applied by roller coating and other methods. Its main function is to prevent rust and can effectively isolate moisture and oxygen from the contact with the galvanized layer.

Topcoat: Choose topcoats of different colors and performances according to your needs to give the color-coated coils rich colors and provide weather resistance, wear resistance and other protection.

(3) Baking and curing

The painted Steel Strip enters the baking furnace and is baked at 180℃-250℃. The high temperature solidifies the resin in the paint into a film, forming a strong coating. The baking time and temperature need to be precisely controlled.

(4) Post-processing

Some color-coated steel coils will undergo post-processing such as embossing and laminating. Embossing increases the surface beauty and friction, and laminating protects the coating surface from scratches.

Advantages and applications

Color-coated steel coils are both beautiful and practical:

Construction field: used for factory exterior walls and roofs, with a variety of colors and durability

Home appliance field: such as refrigerator and air conditioner shells, which are both beautiful and wear-resistant

The transition from galvanized steel coils to color-coated steel coils requires precise process processing. Each production link is crucial, and together they create the excellent performance of color-coated coils, adding color and convenience to modern industry and life.