Innovations and Challenges in Galvanized Corrugated Steel Sheet Production

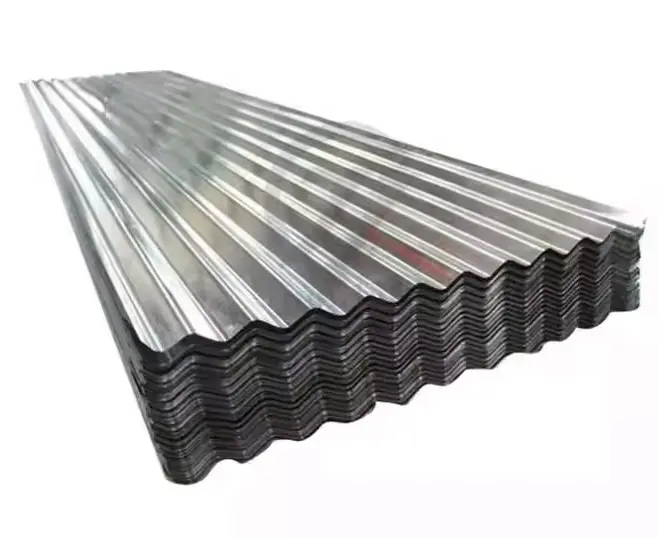

Galvanized corrugated steel sheets, known for their durability and aesthetic appeal, are widely used in construction, packaging, railway vehicles, agricultural machinery, and daily necessities. These sheets, typically ranging in thickness from 0.25 to 2.5 mm, are produced through a continuous hot-dip galvanizing process, which ensures a robust zinc coating that offers excellent atmospheric corrosion resistance, good weldability, and cold-forming properties.

Despite their widespread application, the production of galvanized corrugated steel sheets is not without challenges. Recent advancements and ongoing issues in the manufacturing process have been brought to light, highlighting both the technological strides and the areas needing improvement.

1. Zinc Pot Roller Marks:

One of the significant issues in galvanized sheet production is the occurrence of scratches caused by zinc pot rollers. These rollers, including sink rolls, correction rolls, and stabilizer rolls, operate in a unique position within the zinc bath, making it difficult to equip them with motors for synchronized movement. Consequently, most zinc pot rollers are passive, relying on friction between the Steel surface and the roller to maintain speed synchronization with the strip. However, variations in zinc bath composition and roller usage can lead to insufficient friction, causing relative sliding between the strip and the sink roll, resulting in scratches.

2. Air Knife Streaks:

Streaks can form on the steel surface when the air knife nozzles become partially blocked, leading to uneven zinc coating thickness. These streaks often occur due to sudden changes in air knife pressure during significant variations in production line speed, causing zinc splashes that clog the nozzles. Other contributing factors include improper air knife distance, uneven heating of the strip, and insufficient tension. To mitigate this, operators are advised to control the amplitude during line speed changes, adjust the air knife distance for poor strip shape, and ensure proper tension and stabilizer roll settings to maintain strip flatness through the air knife nozzles.

3. Bare Spots:

Bare spots, or areas where the zinc coating fails to adhere, are another concern. These defects arise when the base metal's surface is not adequately cleaned of oxides and rolling scale before galvanizing. High-strength steels, which contain alloying elements like C, P, and Si, are particularly prone to oxide formation during heat treatment, leading to poor wettability and bare spots. The presence of Si in the base metal exacerbates this issue, significantly impacting the coating's uniformity.

4. Pitting:

Pitting defects, characterized by thinner coating layers in certain areas, are caused by the abrasion of the solidifying zinc layer as it passes through the air knife and minor zinc equipment. These pits are typically the result of small droplets impacting the coating layer. As the coating passes through the air knife, solid particles are blown out, leaving behind pits that cannot be leveled by the surrounding coating due to its semi-solid state.

Innovative Applications:

Despite these challenges, galvanized corrugated Steel Sheets continue to be a versatile material, used not only for structural purposes but also for decorative applications. Their wide range of colors and aesthetically pleasing patterns make them ideal for custom designs, such as advertising billboards and lightboxes.

Conclusion:

The production of galvanized corrugated steel sheets is a complex process that requires precise control and continuous improvement. Addressing the issues of roller marks, air knife streaks, bare spots, and pitting is crucial for enhancing product quality and expanding the material's applications. As technology advances, the industry is poised to overcome these challenges, ensuring that galvanized corrugated steel sheets remain a preferred choice for various industrial and decorative uses.