0102030405

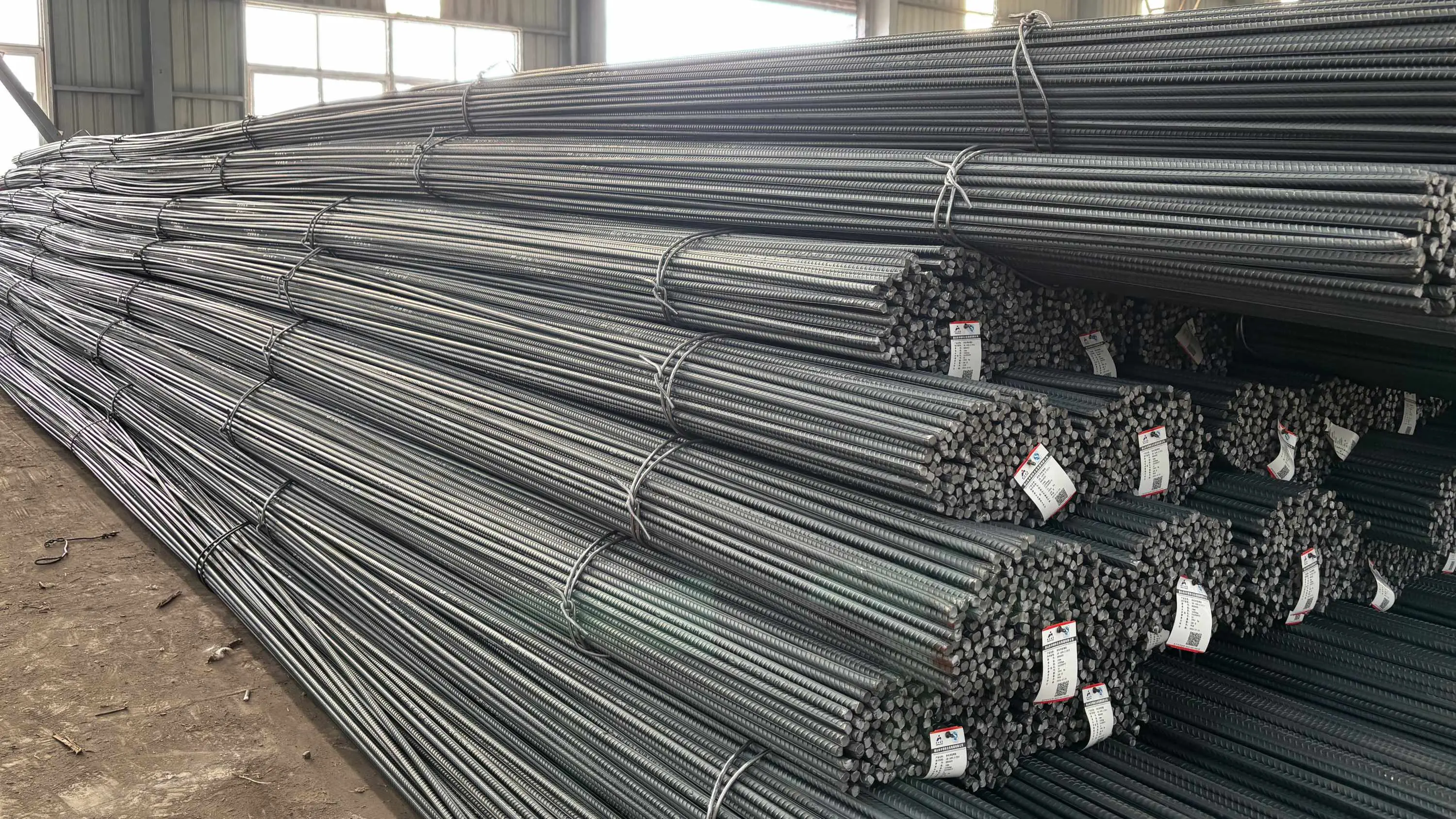

Introduction and Export Trend of Rebar

2025-01-13

Rebar is the common name of hot rolled ribbed Steel Bar, its cross section is usually circular, the surface has two longitudinal ribs and transverse ribs evenly distributed along the length, the transverse rib section is crescent shape, and does not intersect with the longitudinal rib.

The raw materialof Rebar is usually: carbon structural steel or low alloy structural steel.

The production area is divided into: ironmaking area, main steelmaking area and finishing area, and each area is connected with each other.

Production technology: mainly after rolling waste heat treatment technology, fine grain steel bar production technology, slitting rolling technology, no pass rolling technology.

Classification by performance: In the Chinese standard (GB1499), the rebar is divided into 3 grades according to the strength level, which are HRB335, HRB400 and HRB500. In the Japanese standard (JISG3112), the rebar is divided into five types according to the comprehensive performance, which are SR235, SR295, HRB335, HRB400, HRB500.

According to the production method classification: can be divided into hot rolled rebar and cold rolled rebar. Hot rolled rebar is rolled with continuous casting slab or preliminary rolling slab as raw material, which is widely used in building concrete structure. Cold-rolled rebar is made of hot-rolled steel coil, which is acid-washed to remove the oxide and then cold-rolled.

Classification by use: divided into ordinary steel bars for reinforced concrete and heat treated steel bars for prestressed concrete.

Characteristics and application

Features: It has the advantages of high strength, good plasticity, strong gripping force between concrete and can withstand the external force more effectively.

Application: Widely used in highways, railways, Bridges, culverts, tunnels, flood control facilities and building foundations, beams, columns, walls and plates and other structures, is an indispensable important material in civil engineering.

The raw materialof Rebar is usually: carbon structural steel or low alloy structural steel.

The production area is divided into: ironmaking area, main steelmaking area and finishing area, and each area is connected with each other.

Production technology: mainly after rolling waste heat treatment technology, fine grain steel bar production technology, slitting rolling technology, no pass rolling technology.

Classification by performance: In the Chinese standard (GB1499), the rebar is divided into 3 grades according to the strength level, which are HRB335, HRB400 and HRB500. In the Japanese standard (JISG3112), the rebar is divided into five types according to the comprehensive performance, which are SR235, SR295, HRB335, HRB400, HRB500.

According to the production method classification: can be divided into hot rolled rebar and cold rolled rebar. Hot rolled rebar is rolled with continuous casting slab or preliminary rolling slab as raw material, which is widely used in building concrete structure. Cold-rolled rebar is made of hot-rolled steel coil, which is acid-washed to remove the oxide and then cold-rolled.

Classification by use: divided into ordinary steel bars for reinforced concrete and heat treated steel bars for prestressed concrete.

Characteristics and application

Features: It has the advantages of high strength, good plasticity, strong gripping force between concrete and can withstand the external force more effectively.

Application: Widely used in highways, railways, Bridges, culverts, tunnels, flood control facilities and building foundations, beams, columns, walls and plates and other structures, is an indispensable important material in civil engineering.

Overall trend: Global rebar exports as a whole show an increasing trend year by year, but there are certain fluctuations in different regions and time. In 2018, global rebar exports reached about 120 million tons, an increase of about 5% over 2017.

Main export regions: Asia is the world's main production and export of rebar, export volume accounts for most of the world's total export volume, China, India and Japan and other countries are the main export countries in Asia. Europe and North America are also important rebar export regions, and the volume of exports is also increasing year by year. In addition, in recent years, the export volume of rebar in South America and Africa has also shown a growth trend.

Trade friction and policy impact: China's steel products have been subjected to trade remedy original trial investigations significantly increased, as of October 2024 has reached 23 cases. The EU's pilot carbon border adjustment mechanism (CBAM) and similar policies being developed in more countries will put pressure on Chinese steel exports. The China Iron and Steel Association adheres to the principle of "encouraging high-end, restricting low-end, and combating illegal", promotes export tax rebates, cracks down on illegal exports, responds to international trade frictions selectively and systematically, and maintains the share of steel exports.

Contact Us for More Information

Email:manager@fsdsteel.com

Phone/Whatsapp:+86-19133613100