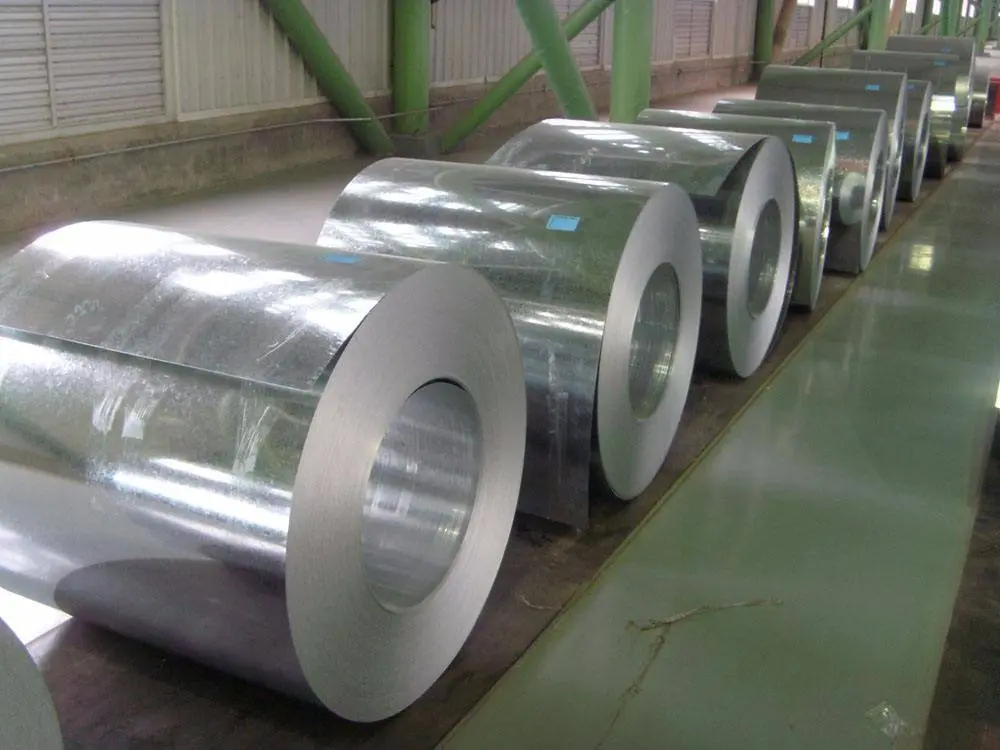

Latest Updates on Galvanized Steel Coils: Models, Materials, and Applications

1. Industry Overview

Galvanized steel coils remain a cornerstone of modern manufacturing and construction due to their superior corrosion resistance, durability, and cost-effectiveness.

With advancements in coating technologies and growing demand from emerging economies, the global Galvanized Steel market is projected to grow at a CAGR of 4.2% (2024–2030).

Galvanized Steel Coil is a corrosion-Resistant Steel product coated with a layer of zinc through a hot-dip or electro-galvanizing process. It is widely used in construction, automotive,

appliances, and manufacturing due to its durability and rust prevention.

2. Key Models & Specifications

Common International Standards:

-

European (EN 10346):

-

DX51D: Basic forming grade (general use).

-

DX52D, DX53D: Improved formability (automotive, appliances).

-

DX54D: Deep-drawing grade (complex shapes).

-

-

Japanese (JIS G 3302):

-

SGCC: Standard galvanized steel (construction, ductwork).

-

SGCH: High-grade (exterior panels, high-corrosion resistance).

-

-

American (ASTM A653):

-

CS Type A/B: Commercial steel (light forming).

-

FS Type A/B: Structural steel (heavy-duty applications).

-

Zinc Coating Grades:

-

Regular (Z60–Z100): Light-duty applications.

-

Heavy-Duty (Z180–Z275): Roofing, industrial use.

3. Material & Coating Technologies

-

Base Material: Cold-rolled steel (SPCC, DC01, etc.).

-

Coating Types:

-

Hot-Dip Galvanizing (HDG): Thicker zinc layer (30–275 g/m²), ideal for outdoor use.

-

Electro-Galvanizing (EG): Thinner, uniform coating (e.g., automotive panels).

-

- Innovations:

-

Magnesium-Aluminum-Zinc (Mg-Al-Zn) Alloy Coatings: Enhanced rust resistance for coastal areas.

-

Anti-Fingerprint Coatings: Used in appliances and electronics.

-

4. Major Applications

| Sector | Uses |

|---|---|

| Construction | Roofing, wall cladding, steel structures, solar mounting systems. |

| Automotive | Body panels, chassis parts, fuel tanks (EG-coated for paint adhesion). |

| Appliances | Refrigerators, washing machines, AC units (anti-fingerprint finishes). |

| Industrial | HVAC ducts, electrical enclosures, agricultural equipment. |

5.Application:

Galvanized sheet (roll) strip products are mainly used in construction, light industry, automobile, agriculture, animal husbandry, fishery and commerce.

The construction industry mainly uses it to manufacture corrosion-resistant industrial and civil building roof panels, roof grilles, etc.;

the light industry uses it to manufacture home appliance shells, civil chimneys, kitchen utensils, etc.;

the automobile industry mainly uses it to manufacture corrosion-resistant parts of cars; agriculture,

animal husbandry and fishery mainly use it for grain storage and transportation, meat and aquatic products freezing processing tools, etc.;

commerce mainly uses it as storage and transportation of materials, packaging tools, etc.

Email:manager@fsdsteel.com

Phone/Whatsapp:+86-18831507725