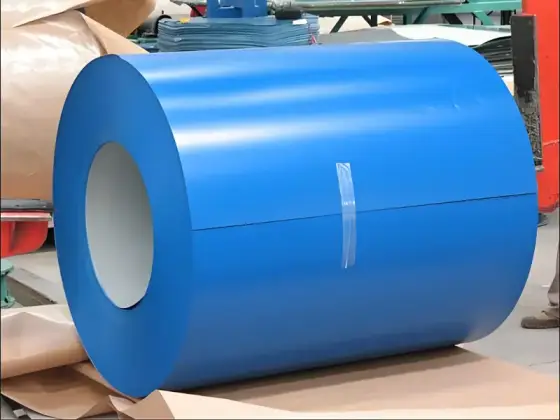

Overview of Color Coated Coil (Color Coated Steel Sheet)

The basic concept of color-coated steel coil: cold-rolled steel strip,galvanized Steel Strip (electrogalvanized and hot-dip galvanized), galvanized steel strip are used as substrates on continuous units.

After surface pretreatment (degreasing and chemical treatment), one or more layers of liquid coating are applied by roller coating. After baking and cooling, the resulting plate is a coated steel plate. At present, there are back (bottom) paint and surface (front) paint coating in China. Generally, there is one layer of back paint and two layers of top paint in China, and two layers of top paint and back paint in foreign business. Since the coating can have various colors, it is customary to call the coated steel plate a color-coated steel plate, also called color-coated coil, color Steel Coil, color-coated steel strip, etc.

Color-coated steel coil = cold-rolled plate + coating (electrogalvanized/hot-dip galvanized/galvanized steel strip) + paint coating

Classification of color-coated steel plates

The types of color-coated plates can be varied, and the specific types can be roughly classified according to the following methods.

According to the front state: color-coated products can be divided into ordinary coated steel plates, printed coated steel plates, embossed coated steel plates and film-coated steel plates, etc.;

According to the coating structure: color-coated products can be divided into 2/1, 2/2, 2/1M, 3/2, etc., */* represents the coating defective products on the front and back respectively;

According to the type of substrate: color-coated products can be divided into high-strength steel color-coated, stamped steel color-coated, general molding color-coated, etc. Specific grades include TDC51D, TDC52D, TS280GD, TS300, TS350, TS420, TS550, etc.;

According to the gloss of the coating: color coating products can be divided into high gloss color coating (gloss greater than 70 degrees), medium gloss color coating (gloss 40 degrees-70 degrees), low gloss color coating (gloss less than 40 degrees)

According to the type of coating: color coating products can be divided into polyester (PE) color coating, high weather resistance (HDP) color coating, silicon modified polyester (SMP), fluorocarbon (PVDF) color coating, etc.;

According to the purpose: color coating products can be divided into color coating for exterior buildings, color coating for interior buildings, color coating for steel windows, color coating for furniture, color coating for home appliances, etc.;

According to the coating characteristics and functions: color coating products can be divided into antistatic color coating, self-cleaning color coating, heat insulation color coating, antibacterial color coating, anti-scratch color coating, etc.

Introduction to color-coated plate substrate (coating)

The intrinsic quality of color-coated plates depends first on the quality of the coating substrate used in the production of color plates, as well as the thickness and process of the coating.

The types of substrate coatings can be divided into the following categories:

1. Cold rolling is directly used as a color-coated substrate after degreasing, cleaning and chemical conversion, and then painted and baked. The disadvantage is that it is easy to rust and has no anti-corrosion ability.

2. Electrogalvanizing is used as a color-coated substrate after cold rolling, electroplating and treatment, and then painted and baked at high temperature. The disadvantage is that because it is cold electroplating and the coating is thin, the adhesion between the coating and the cold plate is not good enough. After a period of use, it is easy to dezincify and itch, which leads to a weakening of anti-corrosion ability. The advantage is that the coating is thin, so the surface gloss is good. It is mostly used in the field of home appliance steel windows and is suitable for indoor use.

3. Hot-dip galvanizing is to treat the cold plate, and then the steel plant uses high-end hot-dip technology to plate a certain thickness and weight of zinc-silicon alloy on both sides of the cold plate, making it have high anti-corrosion and antioxidant capabilities. Because it is hot-dip, the adhesion between the cold plate and the coating is good, the attached coating is thicker and there can be zinc flowers on the surface. After the hot-dip galvanized surface is polished, it is degreased and cleaned by the color coating production line, chemically converted, and finally a certain thickness of paint is coated and baked on the surface to make it a finished product of the color-coated coil. The color-coated coil with hot-dip galvanizing as the substrate has a wide range of uses and is also the most used product at home and abroad. It is mostly used in many fields such as outdoor steel structure buildings, mechanical packaging, and home appliances.

The coating weight is more Z50 grams per square, Z80 grams, Z100 grams, Z120 grams, Z140 grams, Z180 grams, Z200 grams Z220 grams, Z275 grams... It can be selected according to customer needs.

4. Hot-dip aluminum-zinc coating is to treat the cold plate, and the steel mill uses high-end hot-dip plating technology to plate a certain thickness and weight of aluminum-zinc alloy on both sides of the cold plate. The content of each component is standard: 55% aluminum, 43.5% zinc, and 1.5% silicon. It becomes alloy steel wrapped by aluminum-zinc alloy, and its anti-corrosion and anti-oxidation ability is doubled compared with the previous hot-dip galvanizing. Hot-dip aluminum-zinc undergoes the same process as hot-dip galvanizing (degreasing, cleaning, chemical conversion, etc.) and finally a certain thickness of paint is coated and baked on the surface to make it a finished product of aluminum-zinc color-coated coil.

The coating weights are: AZ30g, AZ50g, AZ70g, AZ80g, AZ100g, AZ120g, AZ150g