Quickly learn about the specifications and materials of square rectangular tubes

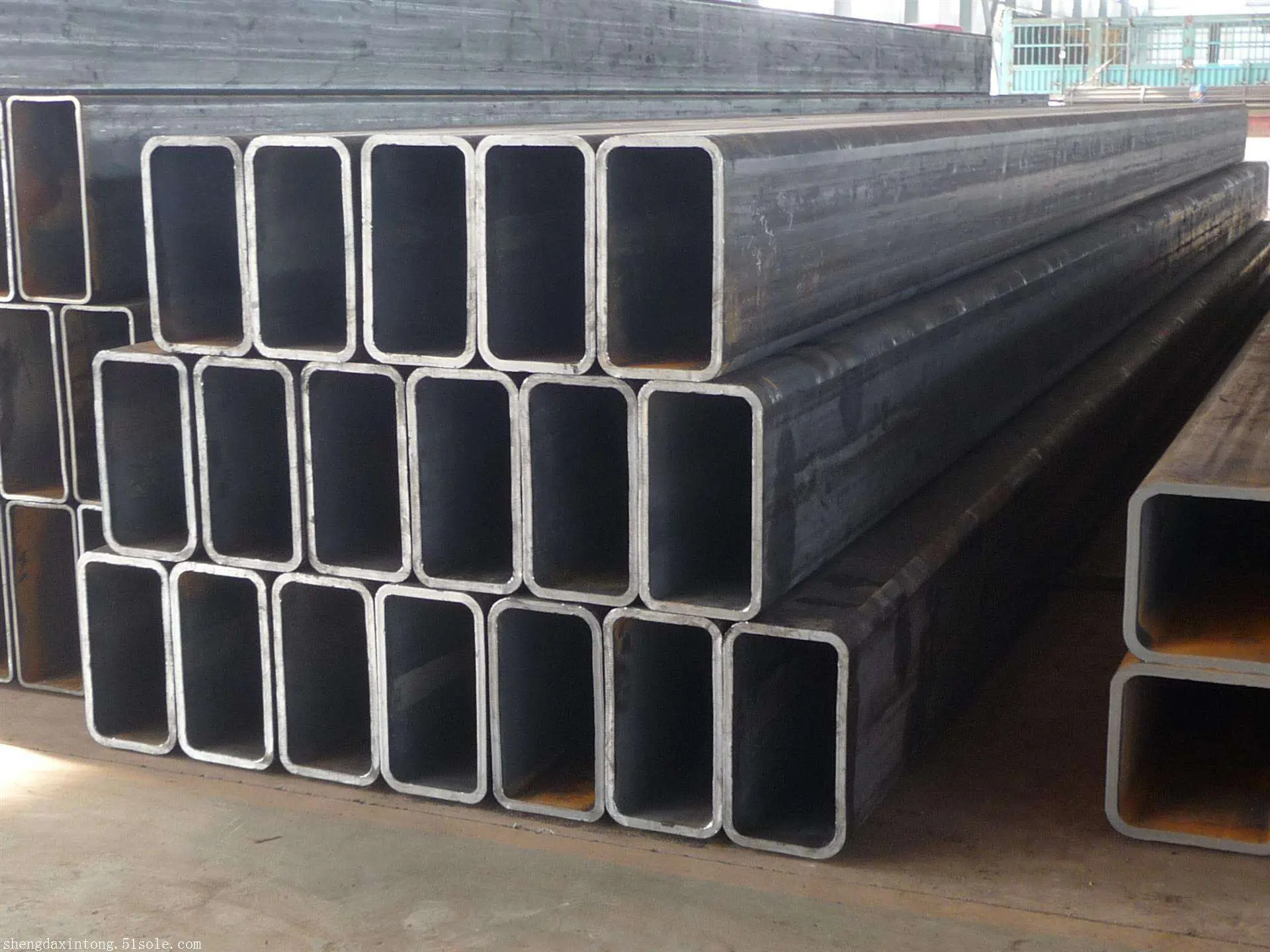

Square rectangular pipes are a term for square and rectangular pipes, which refer to Steel Pipes with equal and unequal side lengths. They are made from strip steel that has been processed and rolled. Generally, strip steel is unpacked, leveled, curled, and welded into round pipes, which are then rolled into square pipes and cut into the required lengths.

Definition and ClassificationSquare tube, as the name suggests, refers to a steel tube with a square cross-section. Rectangular tube, on the other hand, refers to a steel tube with a rectangular cross-section (including square). Based on material differences, square tubes and rectangular tubes can be divided into various types such as carbon structural steel square tubes, low-alloy high-strength structural steel square tubes, and stainleSs Steel square tubes. Among them, carbon structural steel square tubes are widely used in general structural components due to their low cost and good processing performance; low-alloy high-strength structural steel square tubes are used in applications that require higher standards because of their high strength, good weldability, and corrosion resistance; stainless steel square tubes are widely applied in decoration and food machinery fields due to their excellent corrosion resistance and aesthetic appearance.

1. Introduction to Square Tube Products

Square steel pipe is a type of hollow square section lightweight thick walled pipe, also known as steel cold-formed profiles. It is a square section channel steel with a specification made of Q235 hot-rolled or cold-rolled strip steel or coil as the raw material, processed and formed by cold bending, and then welded at high frequency. The specifications of the corners and the verticality of the edges of the hot-dip thick walled square tube, except for the increase in wall thickness, have reached or even exceeded the level of resistance welded cold-formed square steel tubes. Good comprehensive physical properties, weldability, cold and heat treatment characteristics, and corrosion resistance, with excellent low-temperature ductility.

2. Main uses of square tube

The main uses of square steel pipes include engineering construction, CNC equipment, steel construction and other new projects, shipbuilding industry, solar power station support frames, steel structure engineering, power construction engineering, power plants, modern agriculture and chemical CNC equipment, curtain wall glass, chassis, airports, boiler construction, highway guardrails, buildings, high-pressure vessels, oil storage tanks, highway bridges, power equipment, lifting and conveying machinery, and other high load welded components.

3.Classification of Processing Techniques

Square steel pipes are classified according to production processes: hot-rolled seamless square pipes, cold drawn seamless square pipes, extruded seamless square pipes, and welded square pipes.

The welded square tube is further divided into:

(a) Divided by processing technology - arc welded square steel pipe, resistance welded square steel pipe (high-frequency, low-frequency), gas welded square steel pipe, furnace welded square steel pipe.

(b) Classified by welding - straight seam welded square steel pipe, spiral welded square steel pipe.

4.Material classification

Square steel pipes are classified by material into plain carbon steel square steel pipes and low-alloy square steel pipes. Ordinary carbon steel is divided into Q195, Q215, Q235, SS400, 20 # steel, 45 # steel, etc; Low alloy is divided into Q345, 16Mn, Q390, ST52-3, etc.

Classification of Production and Manufacturing Standards

Square steel pipes are divided into national standard square steel pipes, Japanese standard square steel pipes, British standard square steel pipes, American standard square steel pipes, European standard square steel pipes, and non-standard square steel pipes according to production and manufacturing standards.

5.Classification of section styles

Square steel pipes are classified according to their cross-sectional styles:

(1) Simple section square steel pipe - square steel pipe, rectangular pipe

(2) Complex cross-section square steel pipes - flower shaped square steel pipes, open shaped square steel pipes, wavy shaped square steel pipes, irregular shaped square steel pipes.

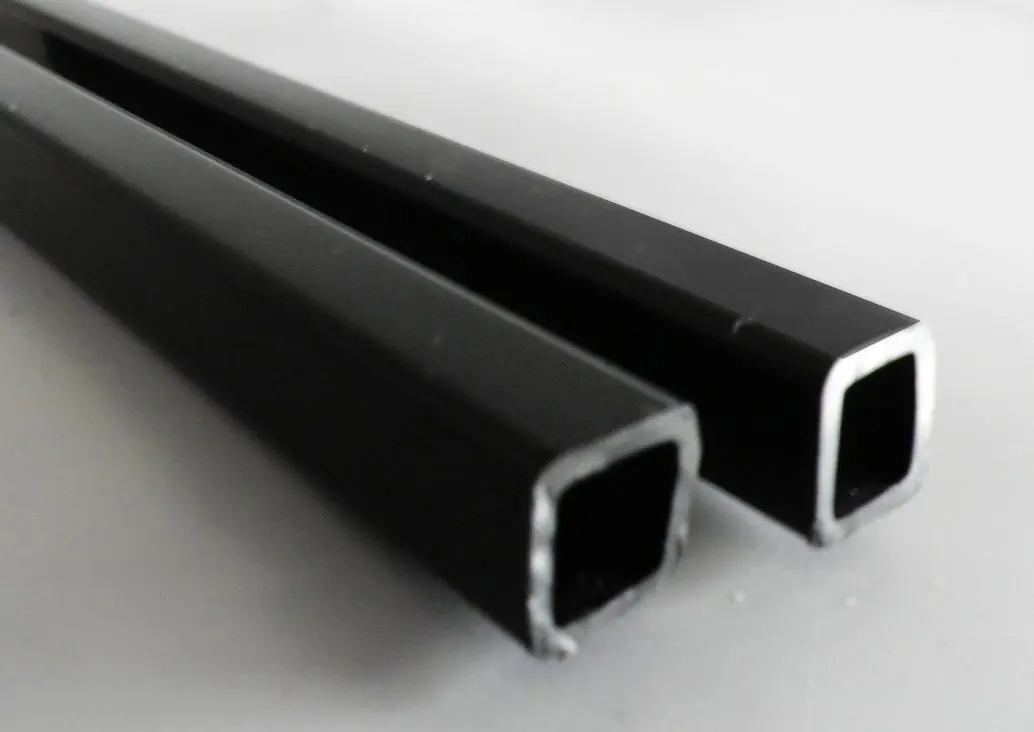

6.Surface treatment classification

Square steel pipes are divided into galvanized square steel, electroplated galvanized steel pipes, oil coated square steel pipes, and acid washed square steel pipes according to surface treatment.

Main purpose classification

Square steel pipes are classified according to their main uses - decorative design square steel pipes, CNC equipment square steel pipes, CNC equipment industrial square steel pipes, chemical plant square steel pipes, steel frame structure square steel pipes, shipbuilding square steel pipes, vehicle square steel pipes, steel column beam square steel pipes, and unique main purpose square steel pipes.

Wall thickness classification

Square and rectangular pipes are classified by wall thickness - ultra thick walled square pipes, thick walled square pipes, and thick walled square steel pipes.