Specifications and models of patterned boards

Patterned plate coilis a Metal Coil with special patterns, which is usually used in interior decoration, building facades, furniture manufacturing and other fields. According to different patterns and manufacturing processes, patterned plate coils can be divided into many categories

.

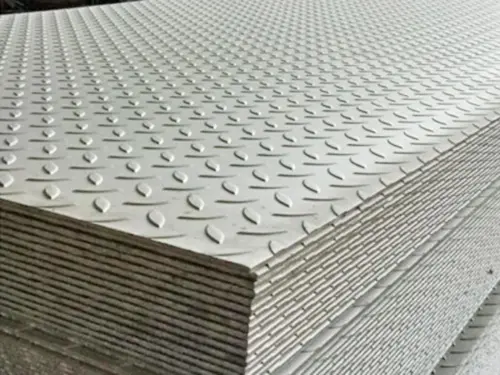

First, according to the shape and texture of the pattern, patterned plate coils can be divided into many types, such as convex patterned plate coils, concave patterned plate coils, hollow patterned plate coils, etc. These different types of patterned plate coils have their own characteristics and can be selected and applied according to different decoration needs.

Secondly, according to different manufacturing processes, patterned plate coils can be divided into two types: cold-rolled patterned plate coils and hot-rolled patterned plate coils. Cold-rolled patterned plate coils are processed by cold rolling at room temperature, and the surface is smooth and uniform; hot-rolled patterned plate coils are processed by hot rolling at high temperature, and the surface is rough and has obvious grain structure.

In addition, according to the style and characteristics of the pattern, patterned plate coils can also be divided into many specific categories, such as geometric patterned plate coils, plant patterned plate coils, animal patterned plate coils, etc. These different patterns can be combined with different processes and materials to meet the personalized needs of different customers.

Finally, according to the different materials, patterned plate rolls can be divided into stainleSs Steel patterned plate rolls, aluminum plate patterned plate rolls, color-coated plate patterned plate rolls and other materials. Different materials have different characteristics and uses, and can be selected according to specific decoration requirements and environmental conditions.

In short, patterned plate rolls have a variety of classifications, which can be classified and selected according to pattern shape, manufacturing process, pattern style, material and other aspects. Different types of patterned plate rolls have their own characteristics, which can provide diversified choices and solutions for different decoration needs.

Patterned plate rolls are a kind of coils with special patterns, usually made of metal or plastic. They have a variety of uses and can be used in architectural decoration, furniture manufacturing, automobile manufacturing, electronic product packaging and other fields.

First of all, patterned plate rolls can be used for architectural decoration. In architectural decoration, they are usually used for the decoration of walls, ceilings, doors and windows and other parts. Because the surface of the patterned plate rolls has special patterns and colors, it can add beauty and artistic atmosphere to the building. In addition, patterned plate rolls are also resistant to mildew, corrosion, and durability, making them suitable for indoor and outdoor decoration.

Secondly, patterned plate rolls can also be used in furniture manufacturing. In furniture manufacturing, they are usually used for the decoration of desktops, cabinets, door panels, and other parts. Patterned plate rolls can be customized with different patterns and colors according to design requirements, which can add a unique style and personality to furniture. Compared with solid wood, patterned plate rolls are lighter, easier to clean, and have stable molding, so they are widely used in furniture manufacturing.

In addition, patterned plate rolls can also be used in automobile manufacturing. In automobile manufacturing, they are usually used for the decoration of car bodies, doors, interiors, and other parts. Because patterned plate rolls have a certain material strength and surface hardness, they can effectively increase the pressure resistance and wear resistance of automobiles. In addition, patterned plate rolls can also choose different patterns and colors according to the design requirements of automobiles, which can provide a rich design selection space for automobiles.

Finally, patterned plate rolls can also be used for electronic product packaging. In electronic product packaging, they are usually used for the packaging of shells, panels, and other parts. Since the patterned plate roll has certain characteristics such as moisture-proof, shock-proof, and heat-insulating, it can effectively protect the safety and stability of internal electronic products. In addition, the patterned plate roll can also be customized with different patterns and colors according to product requirements, which can provide personalized packaging effects for products.

In general, the patterned plate roll has multiple uses and can play an important role in architectural decoration, furniture manufacturing, automobile manufacturing, electronic product packaging and other fields. With the continuous advancement and innovation of production technology, it is believed that their application areas will continue to expand and provide more possibilities for all walks of life.

The patterned plate roll is a common building material, usually made of metal materials such as iron and steel. To melt the patterned plate roll, a series of steps and processes are required. Below I will introduce the melting process of the patterned plate roll.

1. Material selection: First, you need to select the appropriate metal material. Generally speaking, the commonly used materials for patterned plate rolls are low-carbon steel, stainless steel, etc. These metal materials have excellent wear resistance, corrosion resistance and strength, and are suitable for the manufacture of patterned plate rolls.

2. Melting furnace: Put the selected metal materials into the melting furnace for melting. The melting furnace generally uses high-temperature equipment such as electric arc furnace and induction furnace to heat the metal material to a high temperature state and melt it into liquid metal.

3. Casting: Pour the molten metal liquid into the mold of the patterned plate roll for casting. The mold is usually a pre-designed patterned plate roll shape and size, and the metal liquid is poured in and waits for it to cool and form.

4. Quenching treatment: The patterned plate roll after casting needs to be quenched to increase its hardness and strength. Quenching treatment is to place the patterned plate roll in a quenching agent and cool it rapidly, thereby changing the crystal structure of the material and increasing its hardness.

5. Surface treatment: Finally, the quenched patterned plate roll also needs to be surface treated to improve the appearance quality and corrosion resistance. Surface treatment generally includes sandblasting, polishing, galvanizing and other processes.

Through the above steps, the smelting process of the patterned plate roll can be completed. After a strict production process, the manufactured patterned plate roll has excellent performance and quality, and can be widely used in construction, engineering, machinery manufacturing and other fields.