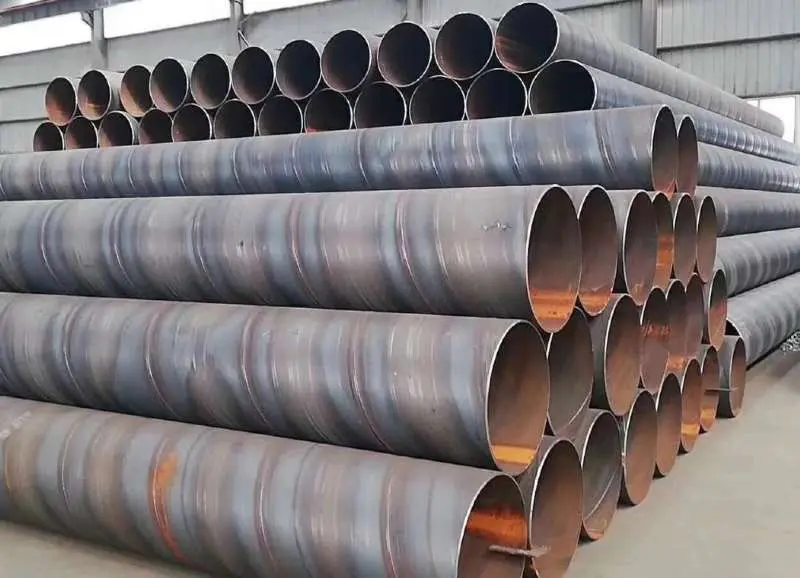

Spiral Steel Pipe: Revolutionizing Infrastructure with Advanced Manufacturing Technology

Spiral steel pipe, also known as spiral seam steel pipe or spiral welded steel pipe, is a steel pipemade of steel plate rolled and made by spiral welding process. The weld of this Steel Pipe is distributed in a spiral shape

1. Structural features: Spiral steel pipe is rolled from steel plate, and the weld is distributed in a spiral shape. Compared with straight seam steel pipe, spiral steel pipe has better bending resistance and pressure bearing capacity.

2. Material characteristics: Common materials for spiral steel pipes are carbon steel, alloy steel, etc., which have good mechanical properties and corrosion resistance. In addition, it can also be customized according to customer needs, such as galvanizing, spraying and other surface treatments.

3. Process characteristics: The production process of spiral steel pipe is relatively simple, the equipment investment is low, and the production efficiency is high. At the same time, the quality of the weld of spiral steel pipe is easy to guarantee, and the quality control in the production process is relatively easy to achieve.

Spiral steel pipe is widely used in petroleum, natural gas, chemical industry, water treatment, construction and other fields. Specifically, it can be used to transport fluid media such as petroleum and natural gas, and can also be used to make chemical equipment, water treatment equipment, building structures, etc. In addition, spiral steel pipe can also be used in marine engineering, bridge construction and other fields.

Advantages:

(1) High structural strength: Spiral steel pipes have high bending resistance and pressure bearing capacity, and are suitable for various complex engineering environments.

(2) Simple production process: The production process of spiral steel pipes is relatively simple, with high production efficiency, which can meet the needs of large-scale production.

Spiral pipes are divided into single-sided welding and double-sided welding. The pipe body should ensure that the water pressure test, tensile strength of the weld and cold bending performance meet the requirements. The strength of spiral pipesis generally higher than that of straight seam Welded Pipes.Spiral pipes can use narrower strip steel to produce welded pipes with larger diameters, and can also use the same width of strip steel to produce welded pipes with different diameters. However, compared with straight seam pipes of the same length, the weld length increases by 30~100%, and the production speed is lower. Therefore, smaller diameter welded pipes are mostly welded by straight seam welding, while large diameter welded pipes are mostly spiral pipes.

Common materials for spiral pipes are: Q235B, 16Mn, Q345B, L245, L290, X42, X46, X60, X80, etc.

Spiral pipes are mainly used in pipeline engineering fields such as petroleum, chemical industry, natural gas, heating, water supply, sewage treatment, piling, dredging, bridges, steel structures, military industry, shipbuilding, pharmaceuticals, papermaking, water supply and drainage, hydropower stations, etc.