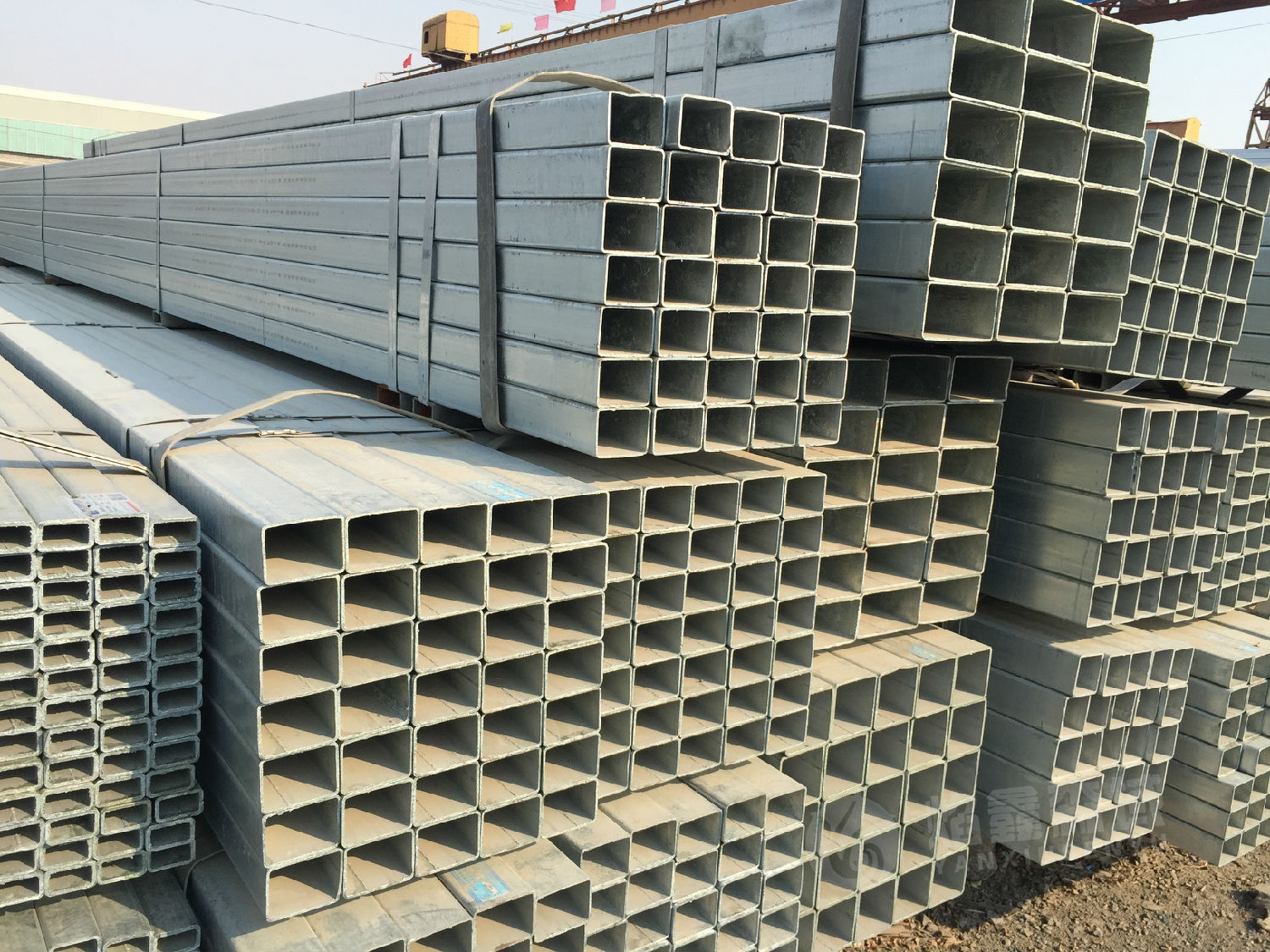

Square Tubes: A Versatile and Essential Material Driving Global Construction and Modernization

Square tubes, a versatile and indispensable material, are playing a pivotal role in global construction and modernization efforts. With their wide range of applications and adaptability, Square Tubes are categorized into four main types based on their cross-sectional shapes: profiles, plates, pipes, and metal goods. This classification simplifies their production, ordering, delivery, and management, making them a cornerstone of industrial and infrastructural development.

What Are Square Tubes?

Square tubesare materials formed by applying pressure to Steel ingots, billets, or other raw materials to achieve various shapes, sizes, and properties. They are a critical component in the construction and implementation of modern infrastructure, particularly in China's ongoing efforts toward its "Four Modernizations." Their versatility and durability make them a preferred choice across industries.

Production Methods of Square Tubes

Square tubes are primarily produced through pressure processing, which involves plastically deforming steel into the desired shape. The production methods are categorized into two types based on temperature: cold processing and hot working. Key techniques include:

-

Rolling

Rolling is a widely used method where metal billets are passed through rotating rollers to reduce their cross-section and increase their length. This process is divided into hot rolling and cold rolling, and is commonly used to produce pipes, plates, and profiles. -

Forging

Forging involves shaping metal billets using the pressure of a press or the impact force of a forging hammer. It is ideal for producing larger cross-sectional materials and is divided into free forging and die forging. -

Drawing

Drawing reduces the cross-section and lengthens the metal by pulling it through die holes. This method is primarily used for cold processing. -

Extrusion

Extrusion forces metal through a die to create products with uniform shapes and sizes. It is particularly useful for producing non-ferrous Metal Square tubes.

Ferrous, Steel, and Non-Ferrous Metals

Understanding the materials used in square tube production is essential. Here’s a brief overview:

-

Ferrous Metals

Ferrous metals, such as iron and its alloys (e.g., cast iron, steel, and ferroalloys), are the foundation of square tube production. Carbon is a key additive in iron-carbon alloys like steel and pig iron. Pig iron, produced by smelting iron ore, is used to create cast iron and steel. -

Steel

Steel is produced by melting pig iron in a steelmaking furnace and processing it into ingots, billets, or castings. Rolled steel is the most common form used in square tube manufacturing. While steel is a subset of ferrous metals, it is often referred to as "black gold" due to its immense industrial value. -

Non-Ferrous Metals

Non-ferrous metals, such as aluminum and copper, are also used in square tube production, particularly in specialized applications requiring lightweight or corrosion-resistant materials.

Applications and Market Trends

Square tubes are widely used in construction, manufacturing, and infrastructure projects. Their applications range from structural frameworks and machinery to furniture and decorative elements. As urbanization and industrialization accelerate globally, the demand for square tubes continues to grow.

Advancements in production technologies, such as improved rolling and extrusion techniques, are enhancing the quality and efficiency of square tube manufacturing. Additionally, the focus on sustainable and recyclable materials is driving innovation in the industry, ensuring that square tubes remain a vital component of modern development.

Email:manager@fsdsteel.com