The basic concept of color-coated corrugated board

Color coated corrugated board is a type of corrugated board made by rolling and cold bending aluminum plates into various waveforms, also known as corrugated aluminum plates, profiled aluminum plates, aluminum tiles, etc. It has the characteristics of light weight, rich color, convenient and fast construction, earthquake resistance, fire resistance, rain resistance, long service life, and maintenance free.

The application advantages of color coated corrugated board:

1. Lightweight: The density of color coated corrugated board is low, only one-third of that of Steel;

2. High strength: Color coated corrugated board can achieve high strength through ingredient configuration, processing, and heat treatment methods;

3. Corrosion resistance: It has strong rust prevention ability, and the formed oxide layer can prevent metal oxidation and corrosion. It has good acid and alkali resistance;

4. Diverse and aesthetically pleasing surface treatments: capable of anodizing, electrophoresis, chemical treatment, polishing, and painting;

5. Color coated corrugated board has good plasticity and is easy to process;

6. Good conductivity: non-magnetic and low spark sensitivity, can prevent electromagnetic interference and reduce flammability in special environments;

7. Easy installation: The color coated corrugated board can be connected by various methods such as riveting, welding, and adhesive bonding;

8. The material used for color coated corrugated board is environmentally friendly and recyclable.

Color coated corrugated board, with its excellent characteristics, is widely used in industrial and civil buildings, warehouses, special buildings, large-span steel structure houses' roofs, walls, and interior and exterior wall decorations, hotels, restaurants' indoor ceilings, airports, train stations, airport terminals, music halls, sports venues, theaters, and more; It is also suitable for roofs, walls, and interior and exterior wall decorations of industrial and civil buildings, warehouses, special buildings, and large-span steel structure houses.

Characteristics of color coated board:

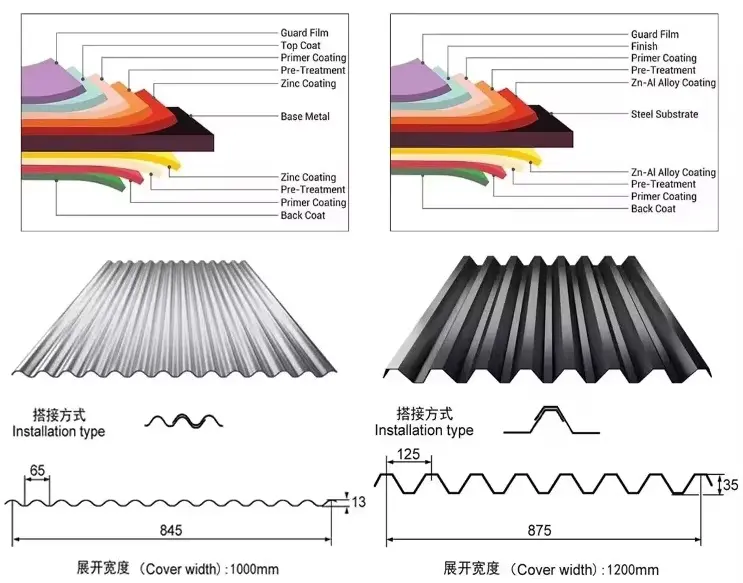

Color coated Steel Plate is a composite material that combines steel materials with organic materials, thus it has the advantages of both: high mechanical strength and good formability of existing steel plates. There are also coating materials with good decorative properties and corrosion resistance.

Application of color coated board:

1. Construction industry: Color coated panels are usually processed into corrugated or Sandwich Panels for application in construction.

2. In addition, doors and windows, rolling shutter doors, and interior decorative ceilings are used.

3. The home appliance industry mainly uses color coated boards to make shells. Such as refrigerator door shell, refrigerator side panel, freezer door body, washing machine shell, microwave oven shell, air conditioning side panel, water heater shell, etc.

The physical properties of the surface of the color coated plate coating include:

The thickness, integrity, hardness, gloss, and color of the coating film.

Main uses of color coated board:

Roofs, roof components, balcony panels, window sills, newsstands, warehouses, rolling shutter doors, heaters, rainwater pipes, etc. in the construction industry

Household appliances such as refrigerators, washing machines, switch cabinets, air conditioners, microwaves, bread makers, copiers, vending machines, electric fans, vacuum cleaners, etc

Furniture industry lampshades, wardrobes, tables, bookshelves, counters, signs, medical equipment, etc

The transportation industry includes car ceilings, car shells, cabin panels, tractors, trams, containers, highway walls, ship compartments, etc

Other aspects include instrument casings, trash cans, billboards, clocks, photographic equipment, measuring instruments, etc

The use of color coated panels in the market is mainly divided into three parts: construction, home appliances, and transportation. Among them, the construction industry accounts for the largest proportion, followed by the home appliance industry, and the transportation industry only accounts for a small part. Color coated panels for construction are generally made of hot-dip galvanized steel plates and hot-dip aluminum zinc coated steel plates as substrates, mainly processed into corrugated panels or sandwich panels that conform to polyurethane. They are used to construct roofs, walls, and doors of industrial and commercial buildings such as steel structure factories, airports, warehouses, and freezers. Home appliance color plates are generally made of electroplated zinc and cold plates as substrates, used in the production of refrigerators and large air conditioning systems, freezers, bread makers, furniture, etc. In the transportation industry, electroplated zinc and cold plate are generally used as substrates, mainly for oil pans, automotive interior parts, etc.

Color coated steel plate and color coated coil are made of galvanized steel plate as the substrate. In addition to zinc protection, the organic coating on the zinc layer plays a covering and isolation role, which can prevent rusting of the steel plate. The service life of coated steel plate is longer than that of galvanized steel plate. It is reported that the service life of coated steel plate is 50% longer than that of galvanized steel plate.