The difference between C-shaped steel and channel steel

In Steel structure engineering, channel steel andC-shaped steel are two common Types Of Steel, which are widely used in different parts of building structures. As a cost estimator, it is important to understand the difference between these two types of steel in order to select the right material and calculate the cost accurately. This article will introduce their differences in characteristics, applications, and specification representation in detail.

1. Difference in cross-sectional shape

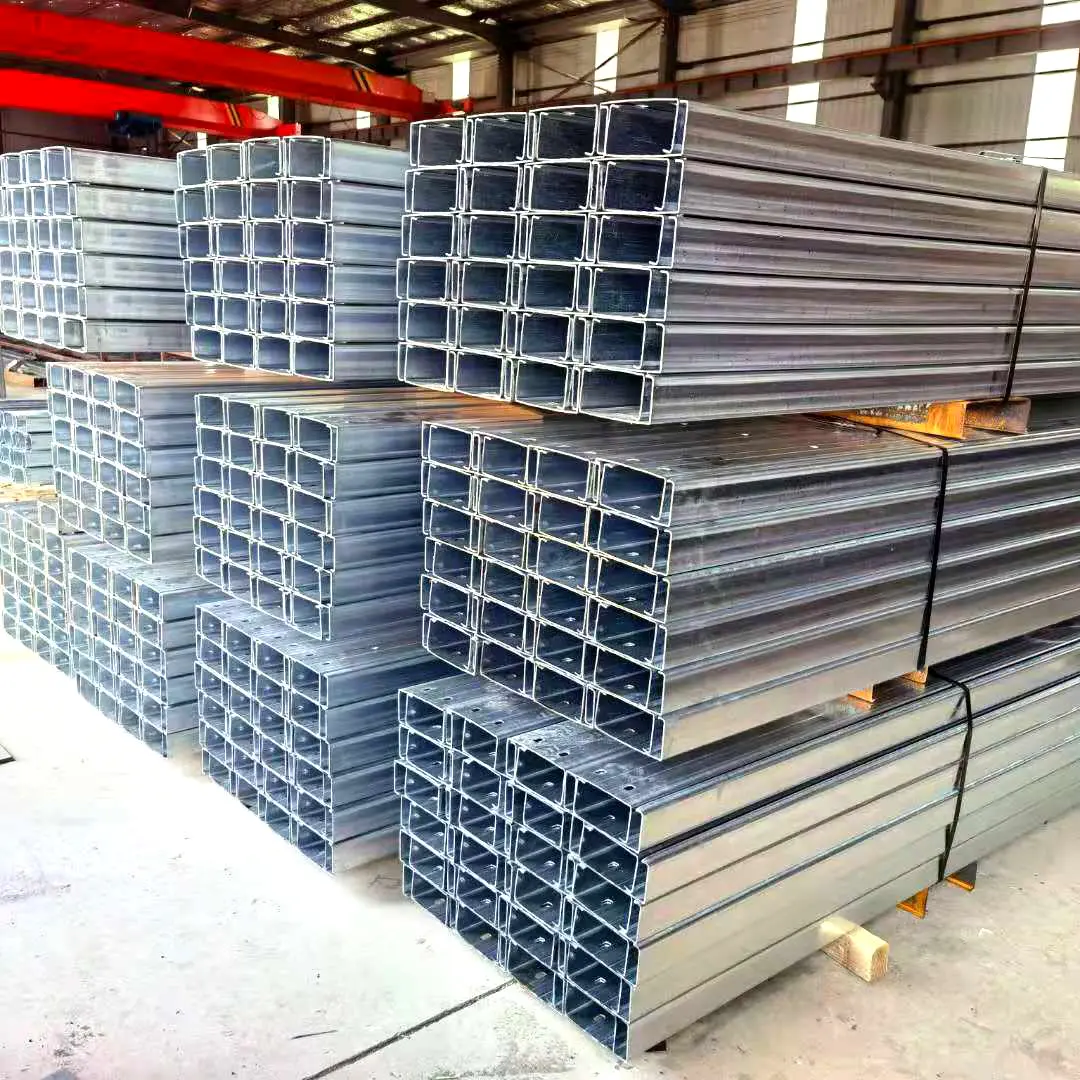

The cross-sectional shape of C-shaped steel is similar to the letter "C". This design gives it a higher advantage in terms of load-bearing capacity and rigidity, and is suitable for constructing beam-column structures for large buildings.

In contrast, the cross-section of the channel steel is "U"-shaped, with parallel flanges on both sides and a web extending up and down in the middle. This structure gives it higher bending and shear resistance, making it suitable for bearing larger bending moments and shear forces.

The difference between the two is that the straight edge is channel steel, and the rolled edge is C-shaped steel.

2. Differences in processing technology and output

C-shaped steelis usually made of thin Steel Plates by cold bending, and its shape is relatively regular, while channel steel is generally hot-rolled, and its two legs are tilted outward. The processing technology of C-shaped steel is relatively simple, and the output is relatively high; the production process of channel steel requires more complex processes, such as cold bending, welding, hot rolling, etc., so the production output is relatively low.

3. Differences in uses and applicable fields

Due to its light weight and high load-bearing capacity, C-shaped steel is often used in purlins, wall beams, roof trusses, brackets and other fields of steel structure buildings. Channel steel has a large cross-sectional area, high bending strength and shear resistance, and is often used in load-bearing components such as beams and columns in building structures

4. Stress characteristics and economy

C-shaped steel is less stressed and is suitable for non-load-bearing enclosure structures, while channel steel is more stressed and can be used as the main load-bearing components such as beams and columns. In terms of price, the production cost of channel steel is higher than that of C-shaped steel, so under the same specifications and quality, the price of channel steel is usually higher than that of C-shaped steel.

5. Differences in expression

C-shaped steel is expressed as C250×75×20×2.5, where 250 represents height, 75 represents width, 20 represents hem width, and 2.5 represents the thickness of the steel plate. The specifications of channel steel are often directly indicated by numbers, such as "channel steel No. 8". The numbers here represent specific size standards, which facilitate communication and understanding within the industry. Specific size parameters can be found in relevant national standards or specifications. In summary, channel steel and C-shaped steel each have their own characteristics and applicable scenarios. As a cost estimator, understanding these differences is crucial for accurately estimating project costs and selecting appropriate building materials. Correctly selecting steel can not only ensure structural safety, but also optimize cost-effectiveness.