The difference between hot rolled steel plate and cold rolled steel plate

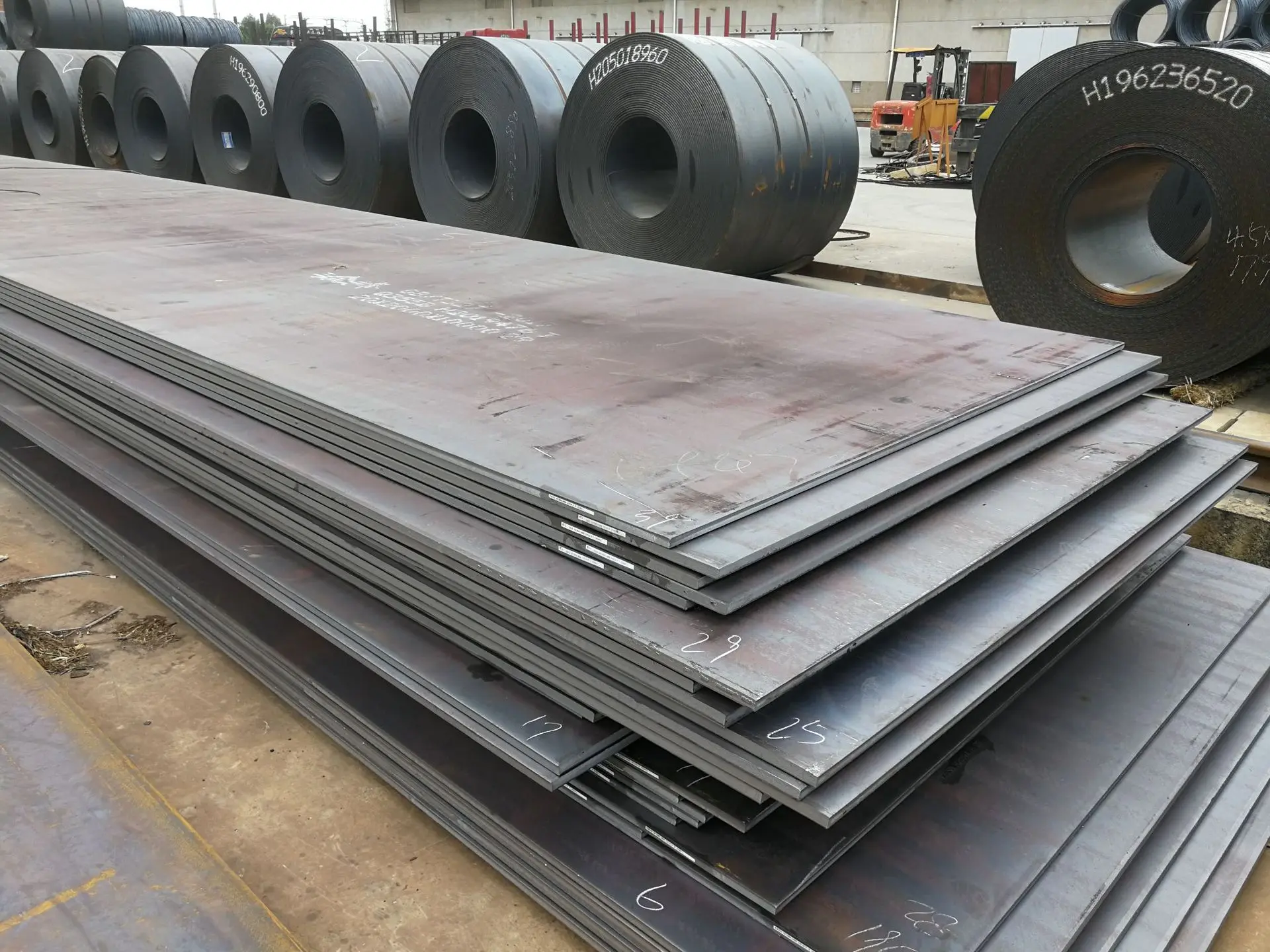

Hot rolled steel plate is a type of Steel produced by a hot rolling process.

The process involves heating the steel plate to a high temperature and then rolling it through rollers to form the final steel plate. The characteristic of Hot Rolled steel plate is that it is processed at a high temperature, which changes the structure of the steel and provides good mechanical and physical properties.

Hot rolled steel plate is an important material in industry and is widely used in many fields. The main feature of hot rolled steel plate is that the production process is carried out at a high temperature, producing a steel plate with high hardness and high toughness. Hot rolled steel plate has a variety of applications and plays an important role in the industrial industry.

Common hot-rolled steel plate types and applications:

Standard:SS400-A36-Q235B-Q345B-Q235-A515-S45C hot-rolled steel plate

Use: used in shipbuilding, structural workshops, oil storage tanks, machinery, construction and other applications.

Russian grades: CT3, CT3πC, CT3Kπ, CT3Cπ… meet GOST 3SP/PS 380-94 standards.

Japanese grades: SS400,… meet JIS G3101, SB410, 3010 standards.

Chinese grades: SS400, Q235A, Q235B, Q235C, Q235D… meet JIS G3101, GB221-79 standards.

American grades: A570 GrA, A570 GrD… meet ASTM A36 standards.

Special high-strength, wear-resistant hot-rolled steel plates

Q345B, C45, 65r, SB410, 15X, 20X and other hot-rolled steel plates

Applications: used in machinery manufacturing, molds, machinery, boilers and other applications.

General specifications of common hot-rolled steel plates:

Thickness: 3mm, 4mm, 5mm, 6mm, 7mm, 8mm, 9mm, 10mm, 11mm, 12mm, 15mm, 16mm, 18mm, 20mm, 25mm, 30mm, 40mm, 50mm, 100mm, 300mm.

Width: 750mm, 1,000mm, 1,250mm, 1,500mm, 1,800mm, 2,000mm, 2,500mm.

Length: 6,000mm, 9,000mm, 12,000mm.

The above provides common types of hot rolled steel plates and their applications in different industries. The diverse hot rolled steel plate size specifications provide flexibility for their use in specific projects and production.

Common Types of Hot Rolled Steel Plates

Regular Hot Rolled Steel: This is a common hot rolled steel plate that is widely used in construction and industry. Its mechanical properties and strength are suitable for many different applications.

High-Strength Hot Rolled Steel: This type of steel plate has higher hardness and strength and is suitable for applications with higher mechanical properties requirements, such as bridges, heavy equipment and other construction projects.

Hardened Hot Rolled Steel: This type of steel is heat treated to increase hardness. It is often used in applications that require high strength and load capacity, such as structural construction and machinery.

Hot rolled steel plate prices

Factors affecting hot rolled steel plate prices

The price of hot rolled steel plates may be affected by many factors, including market supply and demand, raw material price fluctuations, production costs and changes in global economic conditions. These factors may cause price fluctuations and affect the competitiveness and profits of the hot rolled steel plate industry .

By definition, steel ingots or billets are difficult to deform and process at room temperature. They are generally heated to 1100-1250℃ for rolling. This rolling process is called hot rolling. The temperature of hot-rolled plate is high, so the deformation resistance is small and a large deformation amount can be achieved. Taking the rolling of steel plates as an example, the thickness of continuous casting billets is generally around 230mm, and after rough rolling and finishing rolling, the final thickness is 1-20mm. At the same time, due to the small width-to-thickness ratio of steel plates, the dimensional accuracy requirements are relatively low, and plate shape problems are not likely to occur, and the main focus is on controlling convexity. For those with organizational requirements, it is generally achieved through controlled rolling and controlled cooling, that is, controlling the start rolling temperature, final rolling temperature and curling temperature of finishing rolling to control the microstructure and mechanical properties of the strip.

Production process Types and uses

1. Structural steel is mainly used for the production of steel Structures, bridges, ships, and vehicles.

2. Weathering steel adds special elements (P, Cu, C, etc.) and has good corrosion resistance and atmospheric corrosion resistance. It is used in the production of containers, special vehicles, and also in building structures.

3. Automobile structural steel has high-strength steel plates with good stamping and welding properties, which are used in the production of automobile FRAME, WHEEL, etc.

4. Hot-rolled special steel is carbon steel, alloy steel, and tool steel for general mechanical structures. After heat treatment, it is used in the production of various mechanical parts.

5. Cold-rolled original plates are used to produce various cold-rolled products, including CR, GI, color-coated plates, etc.

6. Steel plates for steel pipes have good processing performance and compressive strength. They are used to produce high-pressure gas pressure vessels with a capacity of less than 500L filled with LPG, acetylene gas and various gases.

7. Steel plates for high-pressure vessels have good processing performance and compressive strength, and are used to produce high-pressure gas pressure vessels with a volume of less than 500L filled with LPG, acetylene gas and various gases.

8. Stainless steel plates Stainless steel has good corrosion resistance and is mainly used in the food industry, surgical equipment, aerospace, petroleum, chemical industry and other industries.

Email:manager@fsdsteel.com

Phone/Whatsapp:+86-18831507725