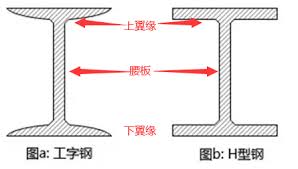

The difference between I-beam and H-beam

H-beam is flat, I-Beam is slanted. Of course, the difference between the two is not just the difference in the inner side of the flange (also called "leg"). H-beam can be divided into piles, columns and beams according to the width ratio of the flange to the web, whileI-beamis basically used as a beam. H-Beam Has the widest application range in steel structure buildings.

1. Whether it is ordinary or light type, the I-beam has a relatively high and narrow cross-sectional size, so the moment of inertia of the two main sleeves of the cross section is quite different. Therefore, it can generally only be used directly for members that are bent in the web plane or to form a lattice load-bearing member. It is not suitable for axially compressed members or members that are bent perpendicular to the web plane, which greatly limits its application range.

2. H-shaped steel is a high-efficiency and economical cutting profile (others include cold-bent thin-walled steel, corrugated steel plates, etc.). Due to the reasonable cross-sectional shape, they can make the steel more efficient and improve the cutting capacity. Unlike ordinary I-shaped steel, the flange of H-shaped steel is widened, and the inner and outer surfaces are usually parallel, which makes it easy to connect with other components with high-strength bolts. Its size constitutes a reasonable series, and the models are complete, which is convenient for design and selection. (Except for I-beams used for crane beams)

3. The flanges of H-beams are of equal thickness, with rolled sections and combined sections consisting of three plates welded together. I-beams are all rolled sections. Due to poor production technology, the inner edge of the flange has a slope of 1:10. The rolling of H-beams is different from that of ordinary I-beams, which only use one set of horizontal rollers. Since its flanges are wide and have no slope (or the slope is very small), a set of vertical rollers must be added for simultaneous rolling. Therefore, its rolling process and equipment are more complicated than ordinary rolling mills. The maximum height of rolled H-beams that can be produced in China is 800mm. If it exceeds this height, it can only be a welded combined section.

I-beam HW HM Hn The difference between H-beam

HW HM HN H is the general name for H-beam, H-beam is welded; HW HM HN is hot-rolled

HW is the height and flange width of H-beam are basically equal; mainly used for steel core columns in reinforced concrete frame structure columns, also known as rigid steel columns; mainly used for columns in steel structures

HM is the ratio of H-beam height to flange width is roughly 1.33~~1.75. Mainly used in steel structures: used as steel frame columns and frame beams in frame structures that bear dynamic loads; for example: equipment platforms

HN is the ratio of H-beam height to flange width is greater than 2; Mainly used for beams;

The use of I-beams is equivalent to HN-shaped steel;

1. Whether it is ordinary or light, the I-beam has a relatively high and narrow cross-sectional size, so the moment of inertia of the two main sleeves of the cross section is quite different. Therefore, it can generally only be used directly for members that are bent in the web plane or to form a lattice-type load-bearing member. It is not suitable for axially compressed members or members that are bent perpendicular to the web plane, which greatly limits its application range.

2. H-shaped steel belongs to high-efficiency and economical cross-sectional profiles (others include cold-bent thin-walled steel, corrugated steel plates, etc.). Due to the reasonable cross-sectional shape, they can make the steel more efficient and improve the bearing capacity. Unlike ordinary I-shaped steel, the flange of the H-shaped steel is widened, and the inner and outer surfaces are usually parallel, which can be easily connected with other components with high-strength bolts. Its size constitutes a reasonable series, and the models are complete, which is convenient for design and selection.

3. The flanges of H-shaped steel are of equal thickness. There are rolled sections and combined sections composed of three plates welded together. I-shaped steels are all rolled sections. Due to poor production technology, the inner edge of the flange has a slope of 1:10. The rolling of H-shaped steel is different from that of ordinary I-shaped steel, which only uses one set of horizontal rollers. Because its flange is wide and has no slope (or the slope is very small), it is necessary to add a set of vertical rollers for rolling at the same time. Therefore, its rolling process and equipment are more complicated than ordinary rolling mills. The maximum height of rolled H-shaped steel that can be produced in China is 800mm. If it exceeds this height, it can only be a welded combined section.

Contect Us for More Information

Email:manager@fsdsteel.com

Phone/Whatsapp:+86-18831507725