Understanding Steel Sheet Piles and Their Uses

Steel sheet pilesrefer to Steel used in bank protection projects, mining projects, and building foundation projects.

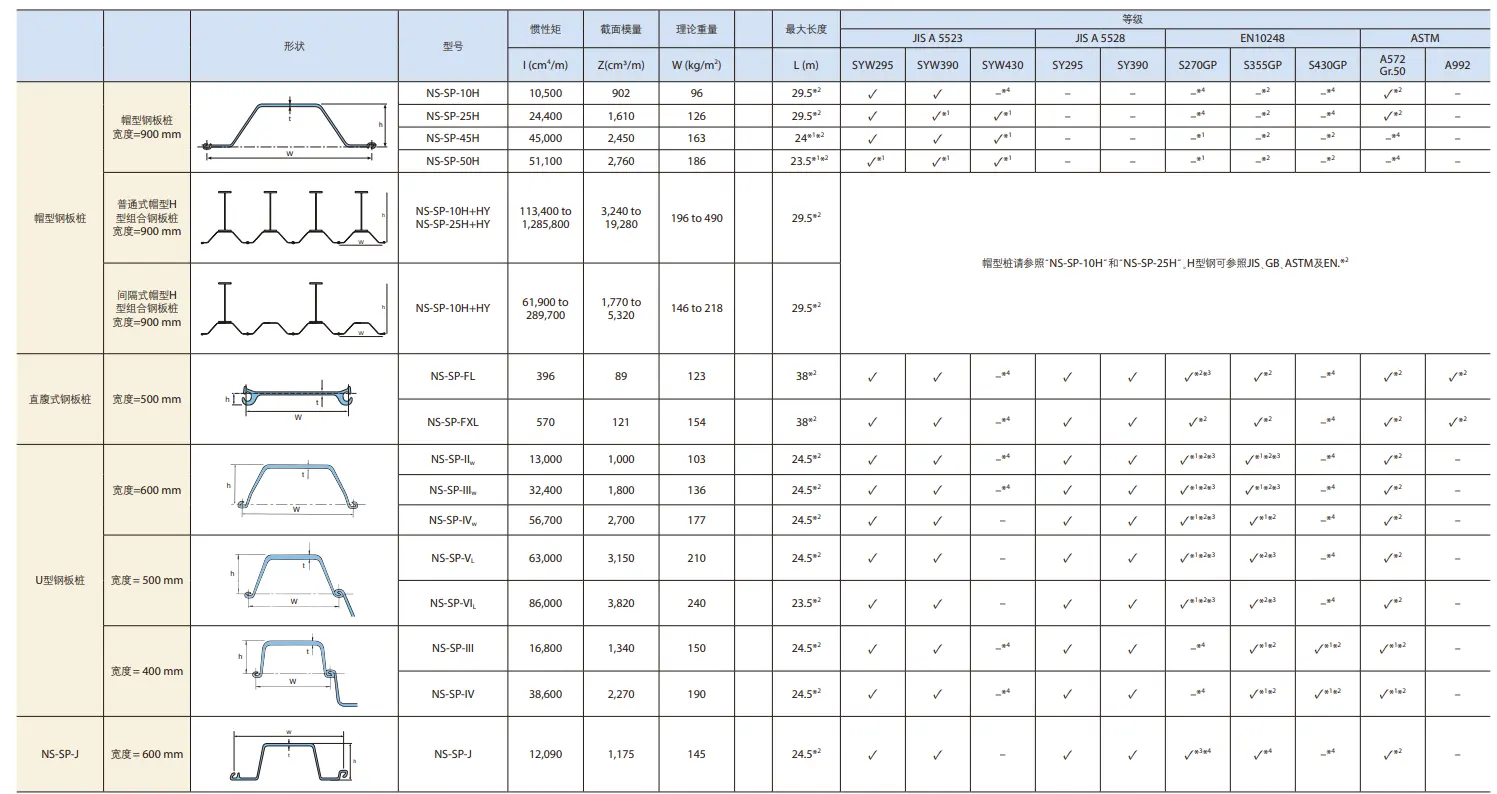

The steel strip is continuously cold-bent to form a plate for building foundations with a cross-section of Z, U or other shapes that can be connected to each other through locks.

Steel Sheet piles produced by roller cold-bending forming are one of the main products of cold-bent steel in civil engineering. The steel sheet piles are driven (pressed) into the foundation with a pile driver to connect them to form a steel sheet pile wall to retain soil and water.

Product use: The uses of steel sheet piles are mainly divided into permanent building structures, temporary building structures, and buildings for emergency rescue.

1. Permanent building structures: highways, railways, docks, embankment revetments, retaining walls, breakwaters, docks, shipyards, gates, downpipes, foundation reinforcement, prevention of collapse, water barriers

2. Temporary building structures: mountain closures, temporary revetments, river interruptions, temporary artificial islands, bridge cofferdams, Large Pipeline laying, temporary ditch excavation retaining walls, water retaining walls, and sand retaining walls

3. Emergency and disaster relief buildings: flood control, landslides, collapses, and quicksand.

Available grades: WBZ450, WBZ500, WBZ550, WBZ600.

Available models and specifications: W-I, W-II, W-IIIa, W-IIIb, W-IV, W-V

Applications: Anti-seepage and water-stopping projects such as embankments and cofferdams, as well as retaining walls, water retaining walls, and building foundation pit support, etc.

Advantages of steel sheet piles:

(1) Fast construction: significantly shorten construction period (masonry walls, concrete walls, etc.)

(2) Structural reliability during long-term use: using high-strength steel sheet piles can increase the safety factor and reduce wall deformation.

(3) Long piles can meet deep burial requirements: up to 38m.

(4) Green and environmentally friendly: can be removed and reused.

(5) Meet construction requirements in narrow spaces.

The following measures can be adopted for steel sheet pile corrosion protection:

(1) Design steel sheet piles under the premise of considering corrosion margin

(2) Concrete coating for corrosion protection:

(3) Steel sheet pile coating for corrosion protection: spray painting, organic lining, mineral lining, inorganic lining

(4) Electrical corrosion protection, impressed current cathodic protection (external power supply method) or sacrificial anode protection (attaching metal materials such as aluminum and magnesium to the steel plate as sacrificial anode).