Understanding Steel Truss Floor Decking in One Article

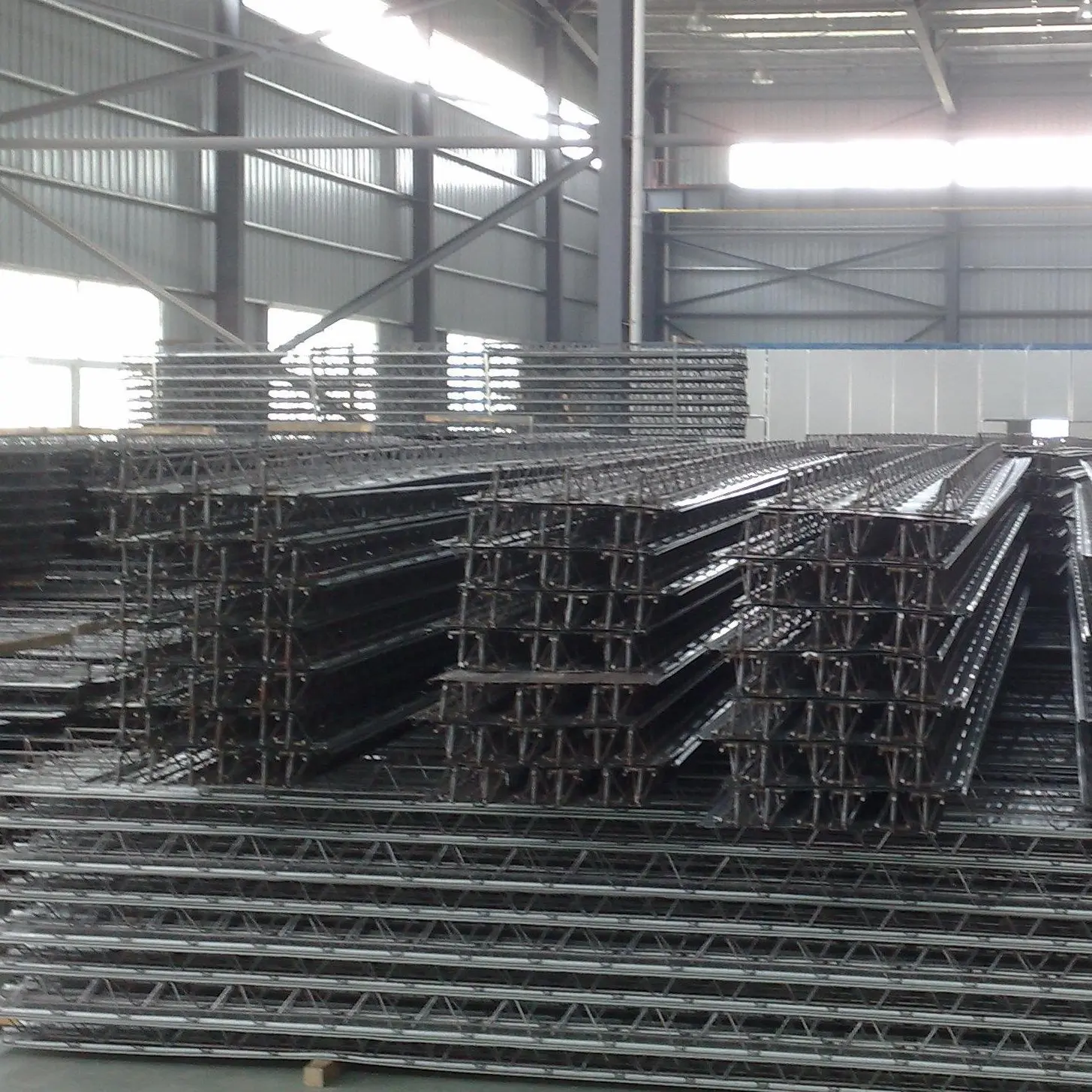

Steel bar truss floor deck is a kind of unsupported corrugated composite floor deck. The trussformed by connecting the upper chord, lower chord and web of Steel Bars by resistance spot welding iscalled steel bar truss.

The combined load-bearing plate formed by connecting the steel bar trussand the bottom plate by resistance spot welding is called steel bar Truss floor deck. Steel bar truss floor deck is a kind of unsupported corrugated composite floor deck; the steel bar truss is finalized and processed in the backstage processing yard. On-site construction requires that the corrugated plate be fixed on the steel beam with bolts first, and then the steel bar truss is placed for binding, and concrete is poured after acceptance.

Prospects for the promotion of reinforced truss floor slabs

(1) Since the reinforced truss floor slabs can be cut and positioned in the factory, there is less waste of steel bars, which saves materials. The floor slab only needs to be tied with distribution bars and connecting bars at the construction site, which can reduce the workload of steel bar tying by 60% to 70%, thereby improving the overall construction speed.

(2) The reinforced truss floor slab is directly supported on steel beams or concrete beams. It is not only the force-bearing bar of the concrete floor slab, but also the floor slab support frame and the formwork of the concrete floor slab. It saves the labor of setting up the support frame and supporting the formwork. It will be more popular in the current era of labor shortage, and it also reduces labor costs, speeds up the construction progress, and has a good effect on reducing economic costs and increasing efficiency.

(3) The stress performance of the concrete floor slab is improved. The deadweight of the concrete slab is completely borne by the steel bars, and no tensile stress is generated in the concrete. The tensile stress of the concrete in the negative and positive bending moment zones during the use period is significantly reduced, which reduces the crack width. The presence of galvanized steel plates prevents the exposure of cracks in the lower part of the floor slab, improving the performance and durability of the floor slab. The steel bars of the floor slab are wrapped in concrete and have reliable fire resistance. Experiments show that when the floor slab thickness is 100mm (the corresponding steel truss height is 70mm), the fire resistance time is 1.68h, and the galvanized steel plate does not need fire protection.

(4) The lower surface of the steel truss floor slab is flat and beautiful, and no corrugation is required. The utilization rate of the galvanized plate is 96%, and the thickness is 0.5mm. Compared with ordinary corrugated steel plates, the steel consumption per unit area is reduced, saving costs.

Advantages of steel truss plates

1. Convenient construction

The steel truss floor slab is light in weight and easy to carry, stack and install. The steel bar cutting, shaping, sizing and binding work are completed in the factory, reducing the workload on site. During the floor slab construction stage, the steel truss floor slab can be directly laid on the beam with the construction load, and the concrete can be poured after simple steel bar engineering.

2. High adaptability

The steel truss floor slab has lower requirements for the bottom plate thickness and galvanizing amount than other slabs. At the same time, the truss height and reinforcement amount can be adjusted to adapt to the large slab span to save construction costs.

3 .Cost saving

The steel truss floor slab can greatly shorten the construction period and reduce the on-site labor cost. For example, it saves the labor cost of scaffolding and formwork, and the amount of on-site steel bar binding is reduced by 60%~70%, which reduces labor and working hours.

4 .Reasonable force

The force mode of the steel truss floor slab is reasonable. The weight of the floor slab is borne by the steel bars, and no tensile stress is generated in the concrete, which reduces cracks in the use stage. The bottom formwork does not replace the stress-bearing steel bars during the use stage, and there is no need to consider anti-corrosion.