Unveiling the Galvanized Color Coated Coil Production Line: A Technological Journey from Steel Coil to "Color Armor"

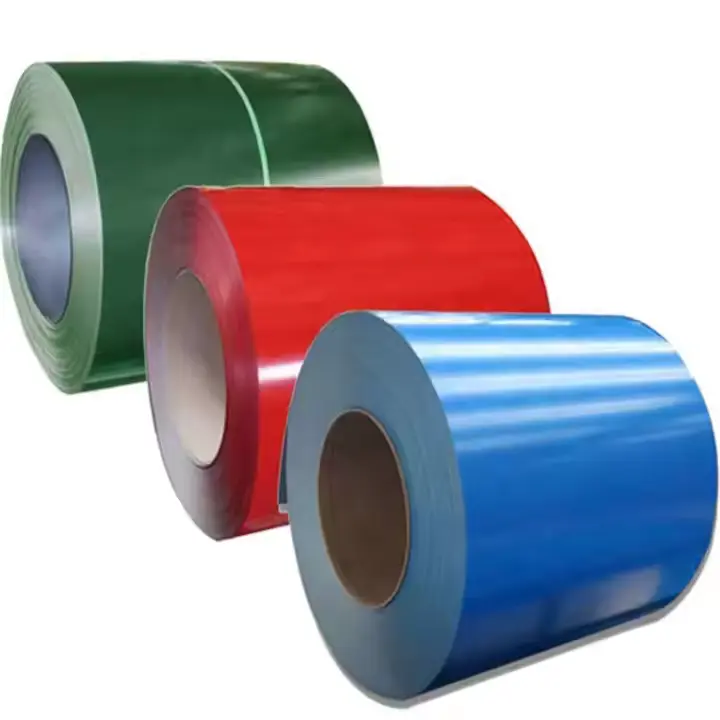

In building roofs, home appliance panels, and even modern art installations, colorful galvanized coated coils are becoming representatives of industrial aesthetics.

How was this material that combines anti-corrosion and decorative properties born? This article will take you into an intelligent Factory and fully analyze the six core production processes ofgalvanized color coated coils.

1、 Raw material preparation: strict selection of cold-rolled steel coils

Substrate requirements: Use SPCC (cold-rolled Carbon Steel) or DX51D+Z (galvanized substrate) with a thickness of 0.2~1.2mm and a surface cleanliness level of Sa2.5.

Pre plating of zinc layer: Some production lines directly use hot-dip galvanized steel coils (with a zinc layer weight of 80-275g/m ²) to enhance the subsequent bonding strength.

2、 Core production process flow

1. Degreasing and cleaning (key pretreatment)

Using alkaline solution (pH 9-11) to remove oil, combined with electrolytic degreasing and high-pressure water spray, to ensure zero residue on the surface.

2. Chemical conversion coating (increases adhesion)

Chromation treatment (or environmentally friendly chromium free passivation) forms a nanoscale phosphate film, which improves the salt spray resistance of the coating by 50%.

3. Initial/Primer Coating

Process: Precision roller coating (coating accuracy ± 1 μ m) or electrostatic spraying

Material: Epoxy resin primer (thickness 5-8 μ m), baking temperature 200-220 ℃

4. Topcoat coating (color and functional layer)

Mainstream coatings:

PVDF (polyvinylidene fluoride): weather resistant for over 20 years, used for landmark buildings

PE (polyester): High cost-effectiveness, suitable for household appliance casings

Technological breakthrough: Some production lines adopt digital printing technology to achieve 3D effects such as wood grain and stone grain.

5. Curing and baking

Three stage oven (preheating → curing → cooling) with precise temperature curve control (± 2 ℃) to ensure complete cross-linking of the paint film.

6. Post processing and detection

Film protection: PE protective film prevents scratches during transportation

Intelligent quality inspection:

Laser thickness gauge (coating thickness error ≤ 0.5 μ m)

Colorimeter (Δ E < 1.0)

3、 Technological upgrade highlights

Environmentally friendly coating technology: the proportion of water-based coatings has been increased to 60%, and VOC emissions have been reduced by 80%

Intelligent temperature control system: AI algorithm based dynamic adjustment of oven temperature, reducing energy consumption by 15%

Defect AI detection: Deep learning identifies defects such as pinholes and holiday coatings with an accuracy rate of over 99.7%

4、 Application scenario extension

Performance requirements for typical applications in the field

Wind pressure resistance and self-cleaning coating for the curved roof of the airport terminal building

Antibacterial coating and smooth touch on high-end refrigerator panels for household appliances

Transportation new energy vehicle battery shell insulation high temperature resistance (200 ℃+)

5、 Industry Trend Outlook

Personalized customization: The proportion of small batch (starting from 100 meters) orders with multiple colors has increased by 25% annually

Functional coatings: New products such as photovoltaic reflective coatings (improving power generation efficiency by 5%) and thermochromic coatings have emerged

Application of Color Coated Steel Coil

1. Construction field: Color coated steel coils are widely used in various fields such as building roofs, wall panels, doors and windows, roof trusses, partition walls, and ceilings. Color coated steel coils not only have aesthetic properties, but also have good waterproof, fireproof, and thermal insulation properties, making them an excellent building material.

2. In the field of household appliances: Color coated steel coils are widely used in the production of household appliance casings, such as refrigerators, air conditioners, washing machines, microwave ovens, and electric ovens. Color coated steel coils have the characteristics of wear resistance, corrosion resistance, easy cleaning, and aesthetics, which can meet the requirements of the home appliance industry for appearance and performance.

3. In the field of transportation: Color coated steel coils can be used to make components such as car body shells, roofs, chassis, and frames. Color coated steel coils have the characteristics of lightweight, high strength, corrosion resistance, wear resistance, and aesthetics, which can improve the safety and aesthetics of transportation vehicles.

4. Furniture field: Color coated steel coils can be used to make furniture such as office furniture, kitchen furniture, bookshelves, and wardrobes. Color coated steel coils have the characteristics of beauty, wear resistance, easy cleaning, and corrosion resistance, which can meet the requirements of the furniture industry for material appearance and performance.

5. In the field of electronic devices: Color coated steel coils can be used to make electronic device casings such as TV casings, audio casings, and computer casings. Color coated steel coils have the characteristics of beauty, wear resistance, corrosion resistance, and electromagnetic interference resistance, which can improve the safety and aesthetics of electronic devices.