What are the commonly used specifications for color coated steel plates? Does it mainly refer to width and thickness?

Color coated steel plates and strips refer to composite materials made by applying one or more layers of organic coatings on the surface of metal substrates after passing through a color roller coating machine.

The purpose of coating is to apply coatings on the surface of objects using various methods to form a dry protective film, which has properties such as resistance to atmospheric corrosion and pollution to protect the substrate. At the same time, it endows the object with advantages such as color, luster, pattern, smoothness, three dimensionality, and good contact, making the object beautiful.

In addition, in special circumstances, there are also products produced for the purpose of electrical insulation, fire prevention, antibacterial, insect proof, bonding, labeling, color adjustment, temperature indication, etc.

Core coating process

Coating: Coating thickness control is a key parameter in the production process of color coated plates. There are two control methods for coating thickness: one is to use pressure sensors, and the other is to use magnetic rulers for control.

We use magnetic ruler+pressure sensor technology, with magnetic ruler control between the feeding roller, measuring roller, and coating roller, and pressure sensor control between the coating roller and the strip Steel. The position values between each roller and the pressure values between the coating roller and the strip steel are displayed on the operation screen, and the thickness is controlled within ± 1 μ.

Roller coating is a coating method that forms a certain thickness of wet coating on a roller, and then transfers part or all of this wet coating to the coated object. It is suitable for the production of flat or strip coatings, characterized by fast speed and high production efficiency.

Width: 1200mm 1150mm 1000mm 950mm

Thickness: 50, 75, 100, 150, 200, 250mm

Length: Sized according to engineering requirements and transportation conditions

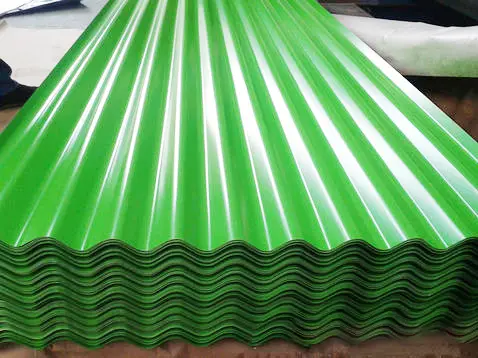

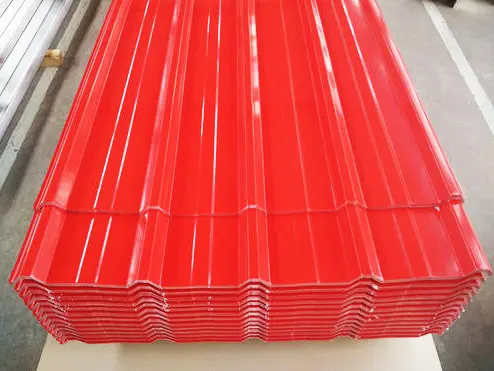

Varieties: H-board, flat board, tongue and groove board, Corrugated Sandwich Panel

Color coated steel plate refers to a type of steel plate with an organic coating. Color steel plates are divided into single panels, color steel composite panels, floor support panels, etc. Widely used on the walls and roofs of large public buildings, public factories, prefabricated houses, and integrated houses.

The substrate of color steel plate is cold-rolled substrate, hot-dip galvanized substrate, and electroplated galvanized substrate. The types of coatings can be divided into polyester, silicon modified polyester, polyvinylidene fluoride, and plastic sol. The surface state of color steel plates can be divided into coated plates, embossed plates, and printed plates. Color steel plates are widely used in industries such as building appliances and transportation. For the construction industry, they are mainly used for roofs, walls, and doors of industrial and commercial buildings such as steel structure factories, airports, warehouses, and refrigeration.

Color steel plate coating is a product made of cold-rolled steel plate, galvanized steel plate, surface chemical treatment, coating (roll coating) or composite organic film (PVC film, etc.), and then baked and cured. Some people also refer to this product as "pre roll coated color steel plate" or "plastic color steel plate". Color coated steel plate products are produced by manufacturers in rolls on a continuous production line, also known as color coated steel plate coils.

Color steel plate not only has the high mechanical strength and easy formability of steel materials, but also has good decorative and corrosion resistance of coating materials. Color steel plate is a highly regarded emerging material in the world today.

With the advancement of technology, the enhancement of environmental awareness, and the improvement of people's living standards, color steel plate movable houses are increasingly showing strong vitality and broad market prospects, and are favored by industries such as construction, home appliances, electromechanical, transportation, interior decoration, office equipment, and others.

The color steel plate activity room has the advantages of lightweight, high strength, thermal insulation, beauty and durability, and is a high-end building that integrates construction and decoration for quick installation.

Color steel plate activity room construction cleaning is widely used in large-span factories, warehouses, office buildings, villas, rooftop floors, air purification rooms, cold storage, shops, vending booths, and temporary buildings. Light colored steel plate sandwich panels with a weight of less than 14KG per square meter can effectively reduce structural loads and lower the cost of prefabricated housing structures.